TOOLING: Let’s Get Serious About Mold Cooling

Cooling is crucial to the molding process yet frequently overlooked. Here are some insights to consider.

Cooling is crucial to the molding process but doesn’t get the attention it deserves. It’s true that lately we’re hearing and reading more about newer technologies like conformal cooling. But the basic methods of cooling—the techniques we have used for years—often are not utilized as well as they could be. (And in the case of conformal cooling, issues with plugged lines from improperly treated water would be a big maintenance concern.) So for this column I would like to provide some insight from the trenches on cooling options and considerations.

Readers of this column know how I transitioned from being a moldmaker in the first half of my career to the molding side in the second half. They are two completely different worlds, and without living on both sides it can be difficult to understand the impacts each has on the other. In the case of cooling, for example, when I was a moldmaker I really didn’t realize how important it was and how it can affect the ability to mold quality parts. So in the mold shop we never got real creative about trying to maximize cooling in difficult areas. But when dealing with problems on the molding side, the desire to be innovative indeed was there. So over the years I have developed a better understanding of options for cooling and what methods should be considered.

Flow volume in gal/min (GPM) and getting proper turbulence in the water flow are very critical to achieving proper cooling, which affects cycle time, the process window, and part quality. Many have heard about the “Reynolds number,” which refers to where the water flow will transition from laminar flow to turbulent flow. If you do not have adequate GPM, have a restriction, or are looping smaller cooling lines in a series with larger cooling lines, you won’t hit that Reynolds number for turbulent flow, and inadequate cooling will result.

Most in the industry use a fluid temperature-control unit (TCU) with centrifugal pumps, which may be unable to maintain GPM if the mold has smaller cooling lines or restricted areas. There are, however, TCUs with positive-displacement pumps that reportedly will maintain a constant flow of GPM up to their maximum flow and pressure ratings. I personally was not aware of this style of TCU until recently when I met with Scientific Molding guru John Bozzelli, a fellow Plastics Technology columnist. He expressed his frustration that the positive-displacement type of TCU is not promoted more widely.

There are many ways to plumb your cooling lines, but you must consider how your choice affects flow. In one approach, a manifold on the mold allows one connection for “In” and one for “Out” on each mold half. Or you can use a series of plumbing lines to reduce the number of connections to equal the number of connections the molding machine has available via the TCU or manifold on the machine.

Or you can opt for an internal flood system, which typically has one main large cooling channel feeding the cross lines. I am not a fan of this approach: If you do not have adequate GPM, the water will flow along the path of least resistance and some cooling lines could receive little or no flow. Also, if you have a plugged line you’d never know it unless it is revealed by poor part quality or you are using a thermal-imaging camera on a regular basis. The same goes for an external manifold, but in this case you can verify each circuit individually if there is a concern. When running water in a series you would know right away if there are any restrictions when verifying flow at setup.

One thing that I learned over the years is that many mold designers fail to take into account the plastic material being molded. I’m not a polymer engineer but I can say with conviction that some materials need molds designed with a greater emphasis on cooling in order to reduce cycle time and eliminate issues with sticking, blow out, warpage, and other quality concerns.

I first started to understand this years ago when we had a sprue-sticking issue with glass-filled nylon. The sprue bushing had some erosion at the nozzle seat, which was contributing to the sticking issue. We had the sprue bushing replaced with a new one. When the tool ran again, the issue was worse than before! It started up all right for the first shot or two, then got worse. This didn’t make any sense, so we covered all our bases by checking the sprue pullers, carriage alignment, and nozzle-tip orifice. Still unable to resolve the issue, we pulled the tool to try to understand what had changed.

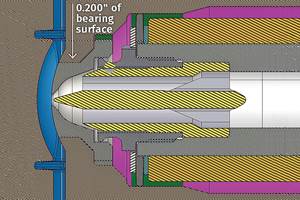

When we removed the new sprue bushing I noticed that the diameter had been relieved to within 0.500 in. at the end. I asked the tool maker why this was done and he responded, “Because it was a tight fit.” Things started to click in my head: This change reduced the amount of contact the sprue had with the cavity block. So in theory it would retain more heat because the contact surface was relieved and was the only area where heat could be transferred. We then installed another new sprue bushing with no relief, which increased the contact area to allow heat transfer to the cavity block. The sticking issue was eliminated.

As this example suggests, it is very important that your molds have cooling near and around the sprue bushings. The same is true with cavity details that cause issues such as blow-out and sticking.

Also, the type of mold steel or alloy needs to be considered when running plastic materials that potentially cause wear and erosion. With abrasive glass-filled materials, for instance, a protective coating should be applied to prevent erosion whenever using special alloys such as Ampco, MoldMax, or Moldstar. These alloys provide much higher thermal conductivity to transfer the heat, but they can be less wear resistant than other mold steels.

Hardened steels are less conductive than untreated steels such as P-20. Hardened H-13 is 15-20% less conductive than P-20, which must be considered when designing adequate cooling channels. From a maintenance perspective, I would still prefer hardened steel to the standard P-20 when running abrasive materials.

It’s the same for cores and inserts. If you are able to get a cooling channel into the detail, a higher-conductivity alloy is not necessary. Bubblers are, in my opinion, the most effective way to provide cooling in tight areas. Many overlook this option. There is also a time and place for heat pipes, but they are not as effective as flowing water. I’ve proven this a few times. But heat pipes definitely have a big impact compared with no cooling at all. I have heard many molders express concerns about plugging issues in small bubblers. This can be a problem when you are not properly treating your water. I myself went through a very frustrating stretch with plugged water lines, so we were acid-flushing tools on a regular basis. With a simple change in water treatment our issues were eliminated.

Next month I will get into more detail on cooling options and some considerations in the design of cooling components.

ABOUT THE AUTHOR

Randy Kerkstra has been in the plastics industry for more than 26 years, occupied frequently with troubleshooting injection molding. He is currently a tooling manager for a large, multi-plant molding and manufacturing company. Contact:kbmoldingsolutions@gmail.com.

Related Content

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreHow to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More