Plastic pollution in the ocean is an international crisis. Estimates are that more than 8 million tons (16 billion lb) of plastics enter the ocean each year, according to the Ellen MacArthur Foundation (EMF). On the current track, there could be more plastics than fish (by weight) in the ocean by 2050.

If there’s one thing we all can agree on it is that no one wants plastics in the ocean. The world’s attention is on this issue and everyone has a role to play. According to Steve Russell, v.p. of the plastics division for the American Chemistry Council (ACC) in Washington, D.C., to fix plastic pollution, we need to solve the right problem. Most of the plastics currently in the ocean are from poorly managed municipal solid waste on land, with about 50% coming from growing economies that do not have systems in place to collect and manage the waste.

There are many companies partnering with governments and nonprofits to prevent waste from reaching the ocean. One big initiative looking to tackle plastic debris specifically from Southeast Asia is Closed Loop Ocean, of which ACC is a partner.

Closed Loop Ocean, an initiative of Closed Loop Partners, N.Y.C., in partnership with Ocean Conservancy of Washington, D.C., is designed to fund waste infrastructure solutions in Southeast Asia, with a focus on investments to improve collection, sorting and recycling markets, particularly across the plastics value chain. At the Our Ocean 2017 conference, Ocean Conservancy and its partners—including the Trash Free Seas Alliance, Closed Loop Partners, ACC, PepsiCo (Purchase, N.Y.), 3M (Maplewood, Minn.), Procter & Gamble (Cincinnati), and the World Plastics Council—announced an initiative to raise more than $150 million for a new funding mechanism to prevent plastic waste from leaking in to the ocean.

“It’s an exciting time in this space, as there is a lot of interest and motivation to do something,” Russell says. “Folks are looking to address this urgent need.”

And there is plenty of movement happening in this area—most particularly, efforts that seek to extract value from the waste plastic. You might have seen the terms “ocean-bound plastic” or “recycled beach plastic,” which are general terms to describe the processes to make a new product out of plastic that was captured before it reached the ocean.

It’s not just a feel-good initiative—though there is that component—or a question of impressive technological breakthroughs, which have indeed been achieved; these companies are also seizing a business opportunity on the sustainability front. The concept is proven but the demand needs to follow for this to become a sustainable business.

CAPTURING OCEAN-BOUND PLASTIC

In 2011, Method, a San Francisco cleaning-products maker, joined forces with HDPE recycler Envision Plastics, Atlanta, to produce prototype bottles out of a novel and new plastic material, ocean PCR (post-consumer recycle). A year later, Method launched its liquid-soap bottles made from 100% post-consumer HDPE, 10% of which was collected from the beaches of Hawaii.

The package captured the imagination of the world. Sandra Lewis, director of business development with Envision Plastics, says the company received all kinds of outreach from people wanting to produce their own ocean-plastic product. “How sad is it that everyone is so excited and wanting to participate, and I had to keep telling them no, over and over again,” she says.

But while the Method package was a proof of concept that the material from the beach could be repurposed into a package, there’s a host of obstacles that come with it. The Method process was limited by collection, processing and degradation issues from the plastic that was gathered on the beach itself. In addition, because of the different types of plastic mixed together, ocean plastic is a gray resin, which can be limiting in the packaging market that often seeks colors. It seemed like this might be a one-off project for Envision.

But then Envision considered a study by the University of Georgia that researched how much mismanaged plastic waste is making its way from land to the ocean. The study found between 4.8 and 12.7 million metric tons (10.6 to 28 billion lb) of plastic entered the ocean in 2010 from people living within about 31 miles of the coastline.

In addition, it emerged that the mismanaged waste and solid-waste disposal was the biggest contributor. For instance, developing nations like Haiti don’t have trash disposal. So, any plastic disposed of within 30 miles or so of the coastline will probably end up in the ocean.

Suddenly Envision had a “light-bulb moment.” Says Lewis, “If we can go into communities and intercept plastic before it reaches the beach or shorelines, we can overcome all those obstacles that were preventing us from helping people who want to use ocean plastic. Getting it before means we don’t have quality problems.”

Envision chose to go straight to at-risk areas around the world to recover the plastics before they enter the ocean. At-risk areas are defined as places where there’s no formal waste system in place for a population living around 30 miles from the coastline. The key is to intercept the plastic before it reaches the beach or enters a waterway.

The company partnered with those on the ground in the at-risk communities to gather HDPE packaging. Envision created a proprietary scorecard to qualify the on-the-ground partners. For example, the partners must abide by set environmental, safety, social and human-rights standards. Envision goes on-site to make sure they know how to properly sort the plastic and load it into containers.

Haiti is one of the countries Envision is working with and there are about 9000 registered collectors who are paid to gather the HDPE material. This showcases that the ocean-bound plastic initiative benefits more than just the ocean, Lewis says. Envision also has a third-party auditor that goes in every country to verify that the collectors are complying with its standards.

THE PROCESS

Envision tracks the material all the way through and immediately inspects the bale when it is received, with no compromise on bale specifications that Envision requires for PCR material gathered from the U.S. Envision keeps the ocean-bound plastic separate from its domestic PCR supply to continue to trace it. After that, it is handled just like standard PCR reprocessing: After bale breaking and hand sorting to ensure there aren’t contaminants, the material is ground into flake, which then passes through an extensive washing process. From there, the material is extruded, filtered and pelletized to eliminate all contaminants. The final step is putting the material through Envision’s patented devolatilization process to remove odor and absorbed chemicals. The ocean-bound material comes out a very high quality and doesn’t have an odor, Lewis says. The material even has a new name: OceanBound Plastic.

“All the obstacles we had before—the bad quality, gray color—are eliminated with this process,” Lewis says. One recent development for Envision is a bottle produced from 100% ocean-bound content, a reported world’s first. The bottle is made entirely from Envision’s OceanBound Plastic and features a silver metallic, pearlescent-effect finish. Envision collaborated with materials designer and colorant supplier Techmer PM, Clinton, Tenn., and blow molder Classic Containers, Ontario, Calif., make such a product possible.

Steve Loney, director of market development for Techmer PM, said that Primal Group, a brand that provides natural personal-care products, was launching a new product range and wanted the bottles to convey a message of sustainability by repurposing waste material. “They basically wanted to create a 100% ocean-bound plastic bottle,” Loney says. “In the past, it hadn’t been 100% ocean-bound, but we were able to overcome some challenges to produce this beautiful silver metallic bottle.”

Techmer PM faced several obstacles, as Primal Group wanted a specific color and reflective finish on the bottle, designed for their new plant-science-inspired personal-care range, ViTA. Typically, an extrusion grade of polyethylene would be needed in the masterbatch as a carrier for the colorant. “But that wasn’t an option in this case because of wanting a truly 100% ocean-bound package,” Loney says. “We made some design changes and manufacturing changes for us to overcome it.”

The high-viscosity OceanBound Plastic supplied by Envision Plastics is a fractional-melt resin that makes it difficult to incorporate the colorant’s metallic particles without shearing them and ruining the ultimate visual effect. Working with officials at Envision’s Chino, Calif., facility, Savvas Roubanis, a sales engineer at Techmer’s Rancho Dominguez, Calif., plant, led the efforts to devise a solution using Techmer PM’s proprietary dispersion technology.

“Compounding of the recipe required additional process design to assure the metallic and pearlescent-effect pigments could be smoothly compounded into Envision’s OceanBound Plastic,” Roubanis says. “In the end, we were able to fully disperse and develop the color and its appearance to the approval of the Primal Group.”

OCEAN-BOUND PLASTICS SUPPLY CHAIN

Envision Plastics also worked with Dell Technologies, Round Rock, Texas, on its first ocean-bound plastic packaging pilot in 2017 using the material as part of a new global packaging system for the Dell XPS 13 2-In-1 laptop. For this project, 25% ocean plastic gathered from Haiti was mixed with other recycled HDPE from sources like bottles and food-storage containers.

In 2017, Dell pledged to increase the annual use of ocean-bound plastic 10-fold by 2025. The company also committed to open-source its supply chain to encourage and enable broad usage of ocean-bound plastics.

During the 2018 Re-focus Sustainability & Recycling Summit at NPE2018, Oliver Campbell, Dell’s director of worldwide procurement & packaging, detailed the ocean-bound plastic supply chain and emphasized that it could be applied to other industries. “I really want to stress that this is not a novelty or a vanity-type project,” Campbell told Plastics Technology. “We took a cold business eye to it about how to solve multiple problems—how to use ocean plastic, intercepting plastic before it goes into the oceans, and how to make it economically feasible. We believe we’ve done that.”

Campbell says that Dell will expand use of ocean-bound plastics to the rest of its XPS NB line this year. And in 2019, Dell plans to use the material in additional products. While the initial project focused on Haiti, the company is shifting to Southeast Asia, specifically Indonesia and India, due to how much marine debris is accumulated there, as well as a cost benefit. “Many people believe that sustainability costs more, and we are here to say that if it’s done correctly, it costs less and can also be a brand advantage,” Campbell says. “This is something customers love and a big win for planet.”

To expand on the ocean plastic project, Dell and Lonely Whale, an ocean conservation group based in N.Y.C. and Seattle, have formed a collaborative and open-source initiative called NextWave, together with General Motors, Detroit; Trek Bicycle, Waterloo, Wis.; flooring company Interface, Atlanta; sustainable furniture company Van de Sant in The Netherlands; office-furniture design company Humanscale, N.Y.C.; skateboard company Bureo, Ventura, Calif.; and furniture company Herman Miller, Zeeland, Mich. NextWave convenes leading technology and consumer-focused companies to develop a commercial-scale ocean-bound plastics supply chain.

NEEDING A HOME FOR THE MATERIAL

Envision felt so sure of the potential for ocean-bound plastics that the company committed to collecting 10 million lb of HDPE from at-risk zones over the next two years. “Instead of just little one-offs and one-time runs with a little bit of ocean plastic, we decided that we’re making this commitment in an effort to bring comfort to brands, so they can commit too,” Lewis says. “We’re approaching the one-year mark and we are right on track, close to having to collect and recycle 5 million lb, but we have sold only about 10% of that.”

Ocean-bound plastic costs more than both virgin and domestic PCR. But Lewis says if more companies expand use of the material, it will eventually get cheaper. “There’s definitely interest out there, but it takes time for companies to make changes and adopt it. We do have a lot in works and are optimistic,” she says. “But we also have a little bit of anxiety about it as we have stuck our necks out there and made the commitment.

We have put a lot of money in it, but more importantly, this program has created jobs. I can’t even think about it not being successful come a year from now when our two-year commitment is over when we have done 10 million lb. If the world doesn’t value that, we can’t keep doing it.”

P&G INITIATIVE IN EUROPE

TerraCycle, Trenton, N.J., specializes in reprocessing hard-to-recycle waste such as coffee capsules, cigarette butts, and industrial waste. TerraCycle collects, converts and sells more than 100 waste streams in over 20 countries around the world that were originally destined for landfills. It was only natural for the company to venture in the beach waste space. Sarah Teeter, the company’s global project manager of beach plastic, says TerraCycle offers unique recycling solutions to give these waste streams a second life. TerraCycle engages with organizations that are already conducting beach cleanups. Previously, material gathered by these groups would be landfilled because of contamination of the material through exposure of the elements.

“We’re working with NGOs (nongovernmental organizations), municipalities and other beach cleanup efforts, and instead of sending material to landfill we are offering a free recycling solution for a more circular option,” she says.

The recovered material is shipped to one of TerraCycle’s warehouses where the staff manually sorts non-compliant items that are considered contaminants, such as organic matter, flexible plastic bags and films, rope, and fishing nets. Once that work is complete, the rigid plastic waste is sent to another processing facility where it is separated by type, cleaned and converted into a usable new format.

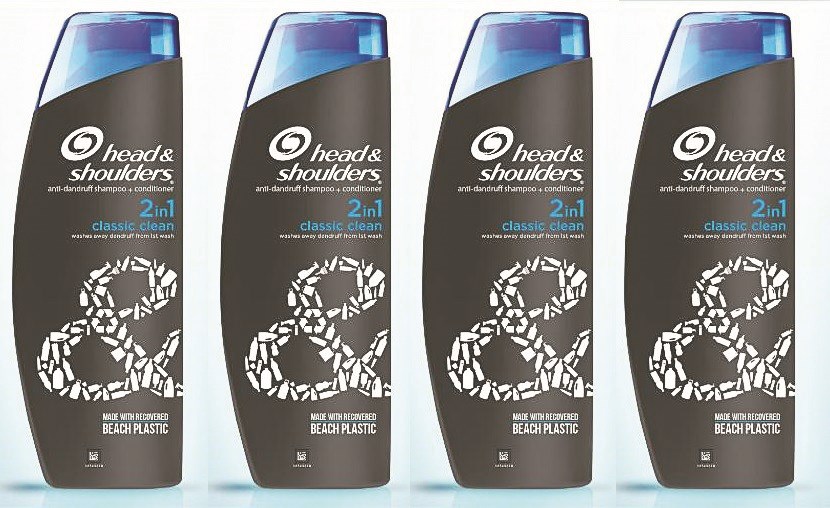

Teeter says that P&G came to TerraCycle in late 2016 with the intention to raise awareness of the marine debris epidemic. The company hoped to recycle plastic that came from beaches into a limited-edition Head & Shoulders shampoo bottle offered in France.

“We thought it was doable to collect beach plastic to convert the material into viable resin that could be used for the Head & Shoulders bottle,” Teeter says. “Since then we have been able to build up a global network of collectors and a successful supply chain to produce a viable resin with this material. There were a lot of technical challenges along the way that we were able to overcome thanks to our in-house R&D group and the technical teams within P&G and their their bottle molders.”

For this project, TerraCycle and P&G worked with Paris-based waste-management company Suez for the different stages of processing, including mechanically sorting the material to separate HDPE, PET, etc. The plastics are shredded, washed and dried to produce a clean regrind. The beach-plastic HDPE regrind is then blended with virgin HDPE and additives. The result is a shampoo bottle made from 25% beach plastic, which was launched in 2017. The Head & Shoulders bottle was awarded the United Nations Momentum for Change Lighthouse award in 2017 for its efforts in tackling the global issue of beach plastic waste.

That beach-plastic bottle is just the start. Since then, P&G announced it will introduce 25% recycled plastic across 500 million bottles sold annually for its hair-care brands. P&G also launched its second ocean-plastic package, the “Fairy Ocean Plastic” bottle made completely from ocean plastic and other PCR. The company again partnered with TerraCycle on that project.

Virginie Helias, v.p. of global sustainability at P&G, says that one of the reasons the consumer-products company launched such an ambitious plan was to increase the awareness of recycling. She also said the extra cost associated with producing this material is not passed on to the consumer.

“There’s no cost to pass on to consumers because we want to do something for the environment and it’s very important to appeal to the mainstream audience,” she says. “It’s the number-one shampoo bottle and it’s not a niche initiative. There is an increased cost in collection and a very manual process with extra cleaning and processing cost, but we are taking it on.”

As this initiative is launching in Europe, P&G wants to bring the beach-plastic packaging to North America as well, but there needs to be more supply. “As supply comes available, we will be able to do it in regions such as North America, Western Europe and Asia,” Helias says.

TerraCycle’s Teeter says Unilever of the U.K. is also interested in bringing the ocean-plastic story to its REN Skincare brand. The company’s new 100% recycled bottle contains 20% reclaimed ocean plastic, which Teeter says is a “natural fit” as the product’s ingredients are from the ocean. This package is also easily recyclable.

Additional products in the range, including hand and body lotions, in the new hybrid recycled/ocean-plastic packaging will be phased in across REN Clean Skincare’s full global distribution by early 2019.

“We hope to see this incorporated in many different products at different scales,” Teeter says. “There is a lot of material out there, so while this might seem like a drop in the bucket, it is one solution to the large problem of marine debris.”

Related Content

Coinjection Technology Showcases Recycled Material Containment

At Fakuma, an all-electric PXZ Multinject machine sandwiches a black core made of mechanically recycled PC/ABS within an outer layer made of chemically recycled ABS.

Read MoreNova Chemicals Attains FDA Letter for Mechanically Recycled LLDPE

RLLDPE product will be marketed for applications including food packaging.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More