Unilever, Alpla, MuCell Combine On New Bottle-Foaming Tech

Dove liquid soap bottles foamed using MuCell technology debut in Europe. U.S. launch is expected soon.

Foamed HDPE soap bottles have landed in Europe. And they’re on their way to North America soon, too.

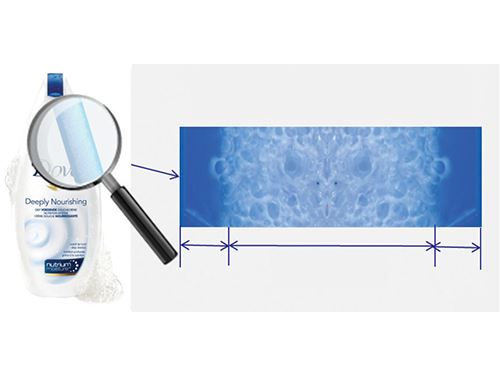

A collaboration between personal-care products giant Unilever, global blow molder Alpla Packaging, and technology licensor MuCell Extrusion LLC led to last year’s European launch of Dove Body Wash bottles that are extrusion blow molded in HDPE with a foamed core layer sandwiched between solid skins. As a result of foaming, each bottle uses at least 15% less material than a typical solid structure. Alpla, which has 152 processing plants in 40 countries, is producing the foamed Dove bottles in Lubeck, Germany.

In 2013, 33 million Dove Body Wash Bottles were sold across Europe. The shift to foaming for that product line alone is expected to reduce the firm’s HDPE consumption by more than 600,000 lb/yr. Unilever says it intends to use this technology across other product lines in the future, and when the program is running full throttle, it could cut material consumption by as much as 59.4 million lb/yr.

Unilever, whose U.S. personal-care business is in Trumbull, Ct., and is headquartered in London, has ordered an undisclosed number of MuCell extrusion blow molding systems to be used at various Alpla facilities worldwide. At press time, one was running in Lubeck, and a second was due to start up shortly.

“This is a long-term collaborative effort between Unilever, Alpla, and MuCell,” remarks Rene Plattner, Alpla regional technical manager for its business with Unilever. “We are taking this brand-by-brand, region-by-region, and machine-by-machine.”

Neither Unilever nor Alpla are strangers to foaming. In 2007, in fact, Unilever worked with Trexel, Woburn, Mass., formerly a sister company of Mucell Extrusion (also in Woburn), to foam injection molded PP margarine tubs. Veriplast International of France—now known as Coveris—molded the tubs. Alpla, meanwhile, started using chemical blowing agents about 20 years ago, Plattner points out.

“We looked at chemical foaming for this bottle project, and still believe that it is an extremely viable technology,” recalls Frederic Dreux, Unilever’s global packaging capabilities leader for rigid plastics. “But we felt for this particular project the MuCell technology would be ideal to reduce material consumption while maintaining product performance.” Consumer studies conducted by Unilever with the Dove bottle revealed that foaming and lightweighting had no impact on perception or preference.

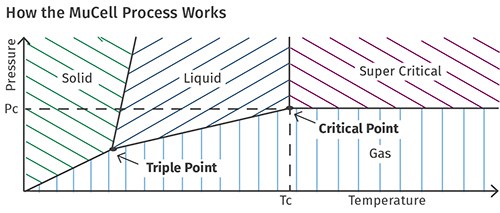

MuCell Extrusion’s technology is based on direct injection of nitrogen or carbon dioxide in its supercritical fluid state. This allows for a single-phase gas/polymer solution. Microcellular structure and controlled product density is achieved by the accurate control of gas concentration in combination with the proper release of extrusion pressure.

This project marks the first time the technology has been applied to extrusion blow molded bottles, though it has been used in Japan to blow mold automotive ducts. Unilever has exclusive rights to the technology in packaging, but only through the end of this year.

Says Paul Howells, Unilever’s v.p. of packaging R&D, “We’re always on the search for new technologies that can help us achieve our ambition to build a more sustainable business and halve our environmental footprint. Working with our two partners, we’ve created a unique technology that will transform our portfolio.”

He adds, “But there’s only so much that Unilever can achieve on its own; and by opening up access to other manufacturers we will really start to see an impact. We very much hope that our peers in the industry will take advantage of this technology, too, and apply it to their products.”

Project discussions between the three parties started around K2010, and Alpla since then has focused on fine-tuning the foaming technology at its R&D facility in Austria, Alpla’s Plattner recalls. “Even with our experience in chemical foaming, this technology was quite new to us. We had to develop a new processing infrastructure from feeding to extrusion to the die head to the blowing station.”

Working with MuCell and its EBM machine builder, Alpla made proprietary changes to extruder screws and barrels and did quite a bit of trial-and-error work to perfect the blowing process.

“That was the biggest challenge,” says Plattner. “With a three-layer structure containing a middle layer of foam, precision in the areas of blowing speed and pressure are crucial to avoid deforming the bottle.” He remarks that the technology is not suited to every bottle design. “Thus far we have found it unsuitable for bottles with sharp corners.”

Adds Unilever’s Dreux, “The objective is to obtain a consistent, regular foam structure by maximizing the number of bubbles and minimizing their size. The bubbles need to form at the right moment in the extruder head.” Dreux indicated that the formulation includes a specialty nucleating agent for the foam.

Unilever would not be specific as to when the technology will launch in the U.S., nor which particular brand will be involved. “Several different brands and bottles are being considered,” says Dreux. Alpla indicated that when the decision is made, it will be supplying bottles from its plant in Jefferson City, Mo.

Notes Mark Lindenfelzer, MuCell Extrusion president, “While consumers won’t see any difference in the bottles, the impact on the environment will be very real. We’re delighted to be part of this development and believe that it marks a real shift for manufacturers who want to behave responsibly.”

Related Content

Services to Help Blow Molders Convert to rPET

Sidel launches “RePETable” range of services as “one-stop” solution to efficient adoption of rPET for bottle production.

Read MoreLighter, Higher Performance Base Design for Premium rPET Bottles

Sidel’s StarLITE-R Premium base for thicker rPET bottles ensures bottle stability in high-speed production, while saving energy.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreFirst Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More