Vision Inspection Integrated with Press Control

Machine-operator access to 100% quality inspection of micro-part dimensions is available with the new PowerVision option from Wittmann Battenfeld, Torrington, Conn.

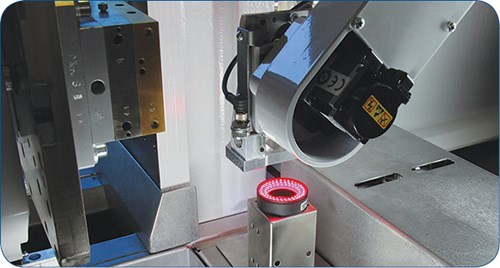

Machine-operator access to 100% quality inspection of micro-part dimensions is available with the new PowerVision option from Wittmann Battenfeld, Torrington, Conn. At the Fakuma show in Germany next month, the company will exhibit a 15-metric-ton MicroPower micromolding system with a Wittmann W8VS2 SCARA robot, In-Sight Micro digital camera from Cognex Corp. (Natick, Mass.), and Cognex In-Sight Explorer vision software integrated with the MicroPower’s Unilog B6 control and the robot’s R8.2 control. The MicroPower press is equipped with a rotary mold table on the ejector side so that molded parts can be inspected outside the molding area without interrupting the cycle.

Related Content

-

Servo-Hydraulic Injection Molding Machine With an Electric Injection Unit Premieres

Fakuma 2024: Wittmann Battenfeld says the 2K SmartPower Combimould features a new electric injection unit option.

-

Innovative Micro-Molding From Minnesota Machine Shop

Machine shops are natural inventors, but not necessarily suited to supporting and marketing a product. This Minnesota shop with an invention related to micromolding will share it through licensing.

-

Precision Processing Requires Precision Equipment

Moretto offers plastics processors and micromolders for a broad suite of auxiliary solutions targeted specifically for precision processing.