What’s New in Mold Simulation

Seamless integration with CAD and FEA structural analysis is a common theme among the major software products.

Over the past year or so, injection molding simulation (or mold analysis, flow analysis) has advanced on several fronts. Seamless integration with CAD and FEA structural analysis is a common theme among the major software products, along with increases in speed, accuracy, and ease of use, plus a variety of new features that provide additional information on a part’s aesthetics, manufacturability, cost of manufacturing, and even environmental impact.

SIMULATION IN THE CLOUD

Through its Autodesk labs research/beta site , Autodesk has allowed customers to experiment for free with a dramatic new capability: simulation “in the cloud”—i.e., using a remote computer via the internet—Autodesk calls this “infinite computing” because it allows access to remote supercomputers to analyze huge simulation models with many millions of mesh elements that would be impractical for many Autodesk Moldflow users to analyze. “Now you can rent a supercomputer for 1 second,” said Brian Matthews, vp of Audesk Labs at last November’s Autodesk University conference in Las Vegas. “It’s not just about doing things better, cheaper, faster, but doing what you couldn’t do at all before.” With cloud computing, intended to be a future commercial service from Autodesk, simulation of very large models, or multiple interations of a simulation, can be performed without tying up a user’s computer for long periods of time. It’s all performed offline and out of sight.

As a demonstration of cloud computing, Autodesk created what’s said to be the largest Autodesk Moldflow model ever—a 3D solid model of a chip-mount connector with 23 million tetrahedral elements. In the real world, a model with 6 million elements is considered very big and would take most users two days of continuous computer time to solve. This “largest ever” model ran “in the cloud” for less than 40 hours.

AUTODESK MOLDFLOW UPDATE

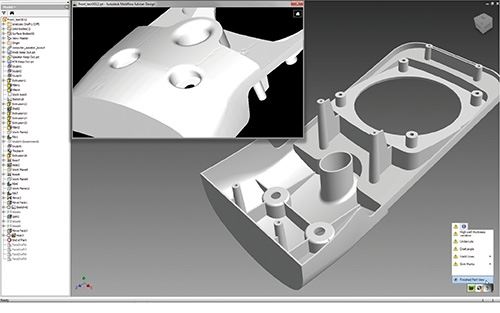

Autodesk has made quite a few upgrades to Autodesk Moldflow Insight and Moldflow Adviser in the 2011 and 2012 releases. Tighter integration with other Autodesk design and simulation products is one thrust. For example Autodesk Moldflow Adviser technology is now embedded in the Autodesk Inventor Tooling design package. Users can perform a quick manufacturability analysis without leaving the Inventor CAD environment. Autodesk Moldflow is also closely integrated with Autodesk Simulation (formerly Algor) finite-element structural analysis software. Autodesk Simulation can now take the fiber orientation simulation from Moldflow to predict anisotropic properties in a molded part.

A third example is Moldflow integration with Autodesk’s Showcase 3D “photorealistic” rendering software. This allows users to visualize the degree to which sink marks and weld lines will present a noticeable aesthetic defect in plastic parts. Users now can see the magnitude of the defect rather than just obtain a numerical indicator. They can also experiment with colors and textures to see how well such defects could be camouflaged.

Integration with Autodesk Inventor Fusion in the 2012 release allows analysts to optimize part or mold geometry without requiring access to the original CAD system in which the part/mold was designed. Even if you do have such access, sorting through the tree history to modify or suppress features can be laborious. With Autodesk Inventor Fusion, you can directly modify geometry from virtually any CAD system to change wall thickness and modify or add/remove ribs and bosses, etc.

NEW SIMULATION FEATURES

Among the numerous enhancements of Autodesk Moldflow Insight and Adviser is a new interface that is more consistent with other Autodesk products. It’s described as more “task oriented,” with toolbars that change according to the task at hand, showing only those tools relevant to the task, and the tools are arranged left to right in a logical order corresponding to the normal sequence of activities. A new View-Cube makes it easier to turn a model and view it from any angle. A new Design Adviser in Autodesk Moldflow Adviser checks a model for undercuts, draft-angle problems, or excessive variations in wall thickness.

Also new is a material-data quality indicator in the Moldflow materials database. Three color-coded levels (Gold, Silver, Bronze) of data quality indicate the level of confidence a user can have in the data, related to the completeness of a data set, extensive use of supplemental data, or unverified test results. Separate quality indicators are provided for filling, packing, and warpage. There are speed improvements for analyzing large models and for cooling analysis. Improved 3D flow simulation now boasts more accurate flow-front temperature calculation and jetting prediction, as well as taking into account gravity effects.

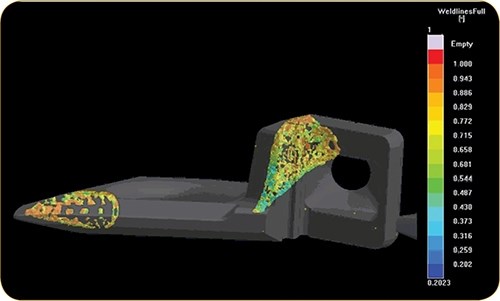

Also improved is weld-line calculation, gate location analysis, injection time prediction, runner-balance analysis, and 3D fiber orientation—which now accounts for orientation effects in the runner. The 2012 release takes this further with improved prediction of short-fiber distribution throughout the thickness of a part and enhanced prediction of long-fiber orientation, taking into account entangling interactions between the fibers.

There’s also new transient mold cooling analysis in Autodesk Moldflow Insight, which no longer assumes constant mold temperature throughout the cycle and from cycle to cycle. It predicts how certain areas of a mold may heat up or cool down during the cycle, and can predict how long it takes mold temperature from startup to reach a stable equilibrium temperature.

Another novel introduction in Autodesk Moldflow Adviser and Insight 2012 is Fill Preview technology, which shows how a part will fill and where weld lines will occur in near real time. The filling pattern updates instantaneously as you move or add gates to a model. Fill Preview is available even before a part is meshed, so you save time by not generating a new mesh for each design iteration. Autodesk Moldflow Adviser Design 2012 includes a new CAD plugin that provides instantly updated indicators of how design changes affect manufacturability, cost, and environmental impact (carbon footprint, energy and water consumption, and recyclability).

Finally, a new optimization analysis in Autodesk Moldflow Insight uses Design of Experiments methods to automatically create a set of simulations to test the limits of every possible configuration of input parameters that you describe by specifying your quality criterial. It then launches all the simulations at once, showing you how each input variable—wall thickness, packing pressure, cooling channel size, etc.—affects critical quality results.

Developmental enhancements in the Project Scandium Technology Preview on Autodesk Labs include improved crystallization modeling to predict part stiffness, shrinkage, and warpage; and venting analysis to predict the pressure buildup due to entrapped air and its effect on the filling pattern.

VISI FLOW ENHANCEMENTS

Like Autodesk, Vero USA, Wixom, Mich., offers injection molding simulation as part of a suite of CAD/CAM/CAE software. VISI Flow v.18 is part of the VISI 18 release last year. It accomplished the full integration of VISI Flow with the firm’s CAD/CAM software so that simulation can be launched from within the CAD environment. New functionality resulting from this integration is a “reverse module,” which allows the deformed part model resulting from VISI Flow warpage analysis to be overlayed onto the original CAD model in order to create a new pre-warped shape with “reverse windage” that is intended to cancel out the warpage effects. Also new is the ability to export the warped model to FEA structural analysis software such as Ansys, Cosmos, or Abaqus.

The new VISI Flow Mesh Wizard has feature recognition for cooling channels and runners and can automatically mesh them in much less time than before. Also new is simulation of overmolding and thermosets such as LSR. Since there has been a scarcity of relevant LSR material data for injection molding simulation, Vero offers to test five LSR grades of the customer’s choice and add those data to the VISI Flow database for that customer.

What’s more, VISI Flow 18 includes a new “Virtual Resin Laboratory” that uses intelligent software to derive data for material grades not already included in the database. The software also calculates an Energy Usage indicator to highlight the energy cost for molding a particular part with a particular material. It also calculates a Recyclability Index for that part and material. A new insert-molding tool can calculate core-pin deflection during molding and the resulting thin and thick areas in the part.

VISI Flow 18 includes a new shell-only meshing option devised mainly for the automotive industry. It enables simulation of just a “skin” of a part in the early design phases when a solid design is not yet available.

This summer, Vero will release VISI Flow 19, with a host of usability and accuracy improvements. These include simplified model preparation and a “transparent mesh” that allows users to look inside the model to better understand part filling. Also, a graphical section can now be cut through the filling analysis result to give a close-up, interior view of the action and analysis variables. Filling analysis is said to benefit from improved flow balancing and fine-tuning of melt compressibility at the end of the filling phase. Holding analysis is improved by fine-tuning the pressure fluctuation length and adding a new variable (Solid Fraction) to better estimate part ejection time. The thermal-analysis module has removed any restriction on the number of circuits, and new circuit management includes automatic setup of cooling circuits, ability to specify different fluids through the circuit layout, and the possibility of running calculations with only selected cooling lines.

Also new is a color-coded “rainbow” chart that indicates quality categories (Easy, Acceptable, Difficult, Not Advisable, Excessive) for molding conditions such as pressure, temperature, shear stress, frozen skin, etc. Molding suggestions are provided, such as reducing injection speed or increasing the molding temperature.

NEW RELEASE OF MOLDEX3D

CAD integration is also part of what’s new in Moldex3D software for filling, packing, cooling, and warpage. It can now be accessed from within Pro-engineer, SolidWorks, and Unigraphics. Building on its earlier integration with FEA structural analysis in Abaqus, Ansys, Nastran, etc., the newest Moldex3D release (R10.0) also is integrated with Code V for plastic optics manufacturing. Code V can now read in warped shape and refractive distribution predictions from Moldex3D to make necessary corrections.

Improving the user experience is a primary focus of brand-new release 10.0. By fully utilizing today’s multi-core, parallel-computing CPU architecture, automated mesh generation is now two to three times faster, as is graphic rendering. Analysis results format has been changed to reduce file size by 40-50% for faster loading. Moldex3D is now also ready for Private Cloud Computing. Jobs can be scheduled for remote uploading to remote computing “farms” and results are automatically downloaded to the user.

New simulation modules can handle injection-compression and gas- or water-assist molding. The new version also enhances simulation accuracy for crystalline polymers with high cooling rates to better estimate packing, shrinkage, and warpage. Expanded viscoelasticity models improve predictions of residual stress and optical performance. Also, warpage prediction is improved with better modeling of mold-temperature distribution and consideration of changes in heat-transfer coefficient at different molding stages.

Moldex3D is a product of CoreTech in Taiwan. Moldex3D Northern America, Inc. is in Northville, Mich. (moldex3d.com). It is also represented by Compuplast with offices in Mississauga, Ont., and Williamsville, N.Y.

SIGMASOFT ADDS MORE VERSATILITY

Sigmasoft simulation software from Sigma Engineering GmbH in Germany is available from Sigma Plastic Services, Inc., Schaumburg, Ill. (3dsigma.com). Developments in the past year have made the software faster overall, making it more useful for analyzing more complex parts. A new release this fall will utilize multi-core processor technology to significantly reduce simulation times.

The current version 4.8 also has several functional enhancements. One is the new Composer and Viewer communication tools, which allow simulation results to be shared among members of a design and development team who don’t have access to the simulation software. The Sigmasoft user can compose a presentation with Composer and share it with the Viewer tool, which other team members can download for free.

Increased accuracy in simulating flow is accomplished with new math models. One is an extensional viscosity model to supplement the usual shear-rate-dependent viscosity model. According to Sigma Plastic Services president Christof Heisser, extensional viscosity is important where there is a large and abrupt change in flow-channel width (greater than a factor of 2). Also, amorphous polymers show significant extensional viscosity effects, Heisser says. Some polymers show a brief increase in viscosity (extensional thickening), followed by a decrease, with increasing extensional rate. This phenomenon is now modeled in Sigmasoft.

Also new in v4.8 is a special viscosity model for very highly filled materials, such as metal or ceramic powder molding compounds. These molten materials behave like a solid when not flowing and being sheared.

Sigmasoft v4.8 now simulates the ejection stage of the cycle to model the deformation of the part and its internal stresses and strains. The loading on ejector pins can also be modeled to predict fatigue, wear, and failure effects.

Another significant addition is the Variotherm option for heat/cool thermal cycling of the mold, a special technique that has aroused considerable interest of late. Sigmasoft has also embedded a virtual temperature controller for hot runners and electrically heated molds. Using tuning algorithms similar to those in actual controllers, the program can find the thermal equilibrium of the mold. One application of this is to determine how many cycles it takes to reach a steady state from startup and then to select a steady-state cycle as the baseline for simulation rather than an earlier cycle when conditions are unstable.

In addition, Sigmasoft v4.8 now can export simulation results to Digimat non-linear micromechanical material modeling software from e-Xstream Engineering. This can be used to transfer the 3D geometry of a weld line into finite-element analysis tools.

Related Content

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreUsing Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More