Wittmann Battenfeld Explains the What & Why of Industry 4.0

Wittmann 4.0 will be the guiding them of the Wittmann Battenfeld exhibit.

There’s a lot going on at the Wittmann Battenfeld exhibit (Booth W3742): six injection molding work cells for medical, packaging, automotive, construction, and consumer electronics; two new injection machines; new robots; and auxiliaries galore for drying, blending, material conveying and loading, mold-temperature control, and granulating. But for David Preusse, president of Wittmann Battenfeld USA, the most important goal for his company at NPE2018 is to communicate two main things:

First, to help clear the air and cut through the bewildering buzz of marketing messages about “Industry 4.0,” the “Internet of Things,” and “Smart Factories,” so that American processors can understand what is happening and why this is probably the most important technical trend they will encounter in their careers in plastics.

And, second, to explain why, in his view, Wittmann Battenfeld is ahead of the pack in implementing this technological revolution.

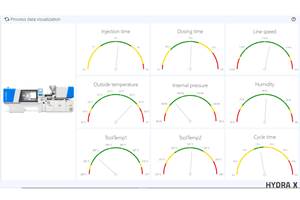

Preusse eagerly looks forward to the “smart factory” in which, for example, it is possible to set up all equipment in a cell—molding machine, robot, dryer, blender, chiller, etc. from a single point. “Now, instead of running around to a bunch of different controllers in a molding cell, everything is on the injection machine controller, all alarm conditions are central and uniform, and any of these alerts can be seen in real time on the user’s phone or MES system.” Job changes would be quicker and freed from errors such as forgetting to turn on or correctly set the temperature controller. In such a plant, “one may not need to gown up to enter a medical clean room when remote controls are accessible nearby.” And imagine sensors all over a machine “to make the machine smarter about its own health conditions—not unlike monitors on our cars today that tell us when our tires are low on air, so we can refill them at the next gas stop instead of getting stuck with a flat tire.” What’s more, “4.0 systems are tied into the customers’ MES system for better production planning; and it’s easy to have your supplier online in real time with Web Services to provide support, advice, spare parts, or troubleshooting.”

These are just a small sample of the benefits anticipated from Industry 4.0, and Preusse’s big point is that you can see them in action right now in Wittmann’s booth. Not just in the molding work cells—one of which integrates the press controller with a robot, TCU, blender, dryer, hot-runner controller, etc. There’s also a simulated live molding cell in which visitors can modify the equipment configuration to experience Wittmann’s “Plug and Produce” capability.

According to Preusse, what puts Wittmann in a unique position to carry the ball for Industry 4.0 ahead of the rest is its product line of injection machines and most of the common auxiliaries needed to operate a molding cell. “Most molders buy equipment from many different suppliers,” Preusse notes, and it would be a Herculean task to try to integrate them on their own. While a number of machine suppliers are working together in various industry associations to develop uniform data-exchange guidelines, that will take some time to complete. But Wittmann Battenfeld has its own hardware and software ecosystem in which it has been able to institute uniform communications protocols, which it calls Wittmann 4.0.

The heart of that system, says Preusse, is the Smart Link router. “It provides data security throughout the system. Only devices that identify themselves with a security certificate are allowed access to the production cell. The next issue it solves is that configurations of auxiliary equipment are ever changing on the shop floor. Each mold, for example, requires a different set of temperature controllers, dryer, blender, robot tooling, etc. The Smart Link router provides immediate and effortless changeover by keeping track of all the devices’ IP addresses. And Wittmann 4.0 stores the setup data for all these devices in the injection machine controller.”

Related Content

Four Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreBeyond the Work Center: Using MES for Data-Driven Decisions Across Manufacturing Operations

Move past “is the job running” and “will it finish on time,” and apply MES to inform workflows ranging from accounting, inventory control, planning, material logistics, quality assurance, engineering and shipping.

Read MoreManufacturers’ Superpower: ‘X-Ray Vision’ into Your Processes

Meet a ‘new’ name (to North American processors) in MES software, which provides a simple, modular way to achieve visibility into your production operations.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More