Wittmann’s 40th Anniversary Gala Unveils New Products

New machinery, robots, and auxiliaries demonstrate continued momentum of technical development—and preview some K 2016 exhibits.

Starting with a single product, a water regulator, in 1976, Wittmann Group has grown into a global power in injection machinery, robots, and a wide range of auxiliaries—including water-manifold regulators. Still family-held, Wittmann Group (wittmann-group.com) now employs 2050 people at 36 locations worldwide and is closing in on a goal of 400 million Euros annual revenue for 2017.

In June, 1650 customers and business partners gathered in Vienna, Austria, to help founder Werner Wittmann and his two sons, Michael and Thomas, celebrate this achievement. The company showed how far it has come, and where it is going, with 10 injection machinery demonstrations and exhibits of its full product line—10 injection machines and work cells, plus 65 robots and auxiliaries—including many new developments in all categories, the fruit of devoting 6% of revenues to R&D. Wittmann also offered plant tours to show off its latest expansions, including a new tech center, completed this year, for demonstrating large machines at Kottingbrunn, Austria.

INJECTION MACHINERY NEWS

One important development highlighted in the machinery exhibits was the brand-new Unilog B8 controller, which will also star at October’s K 2016 show in Dusseldorf. It is distinguished by its larger,

21.5-in., full-HD screen with multi-touch (gesture) functions such as wiping and zooming, as on a tablet or smartphone. The swiveling screen is divisible into sections to display more than one page at once. In addition, the Unilog B8 retains some hardware keys for frequently used functions. Exhibited for the first time in Vienna on an all-electric EcoPower 110, the new control will be available soon after the K 2016 show.

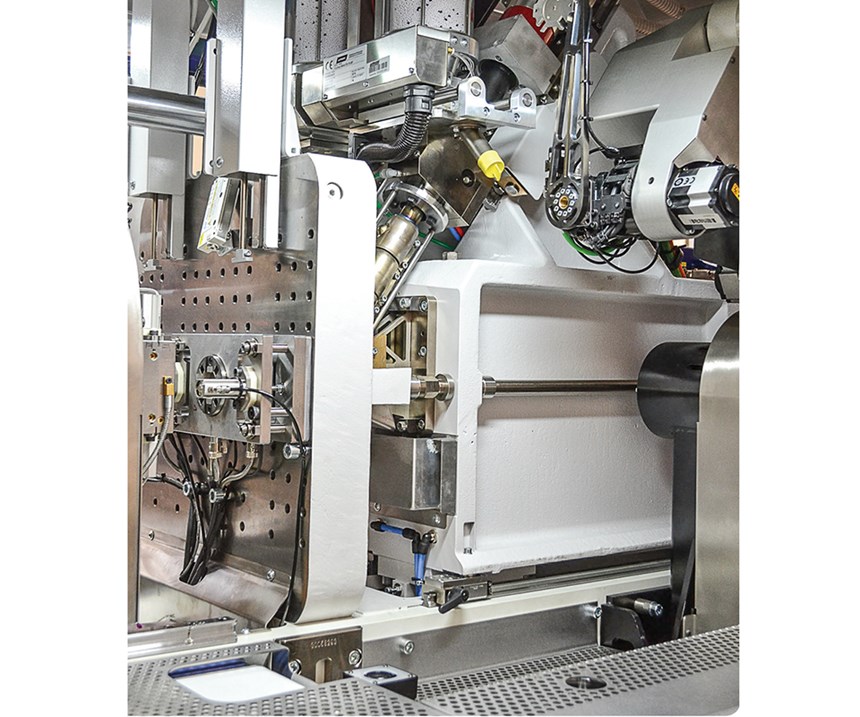

The Wittmann Battenfeld MicroPower all-electric micromolding system was shown for the first time in a two-component version, molding an electronic connector for a disk player out of conductive and non-conductive acetal (POM) in shots of 3 mg and 90 mg, respectively. The 15-metric-ton (m.t.) press has two parallel injectors and a high-speed rotary table. It will also be exhibited at K 2016.

A second MicroPower demonstration featured the first use of a hot runner in this machine. It molded 0.05 g PBT connectors in eight cavities. The hot runner was developed together with the customer. It holds 4-5 g and has an open hot tip. The value of a hot runner in micromolding, where scrap often cannot be reused, is evident in the previously mentioned exhibit, where the sprue weighs 140 mg—50% more than the part.

Last year at the Fakuma 2015 show, Wittmann Battenfeld introduced the medical version of its EcoPower all-electric machine adapted for clean rooms (see Nov. ’15 Keeping Up). In Vienna, the company announced that its SmartPower servohydraulic press is also available in a clean-room version.

A sign of Wittmann Battenfeld’s renewed effort to stimulate interest in its Cellmould microcellular foam process was the demonstration for the first time on a Smartpower servohydraulic machine. It was shown on one of the new, larger models (240 m.t.). Another first was the combination of Cellmould with the BFMold (Ball-Filled Mold) tooling concept for hot/cold molding in order to produce a high-gloss surface on the foamed part.

ROBOTS & AUXILIARIES

Wittmann is expanding its W8 pro range of servo robots into larger sizes. While previous models handled payloads of 20-35 kg (44-77 lb), the new W853 pro and W863 pro can carry 50 and 75 kg (110 and 165 lb) respectively.

On the smaller end of the size range, Vienna saw the debut of a prototype of the compact WL80 servo robot, designed for pick- and-place applications on 30-60 ton machines. It has a 4.4-lb payload capacity and R8 control. Designed particularly for the Asian market, it comes with optional pneumatic C wrist-flip axis and optional sub-arm for three-plate molds.

Meanwhile, Wittmann’s WS80 servo sprue picker, introduced in 2014 (see Dec. ’14 Fakuma Close Up), is now available with Net8 control for use on any brand of injection machine.

A new standard option for Wittmann robots is the integrated control of machine-vision cameras from Cognex Corp., Plymouth Meeting, Pa. (cognex.com). The camera can be controlled from the robot Teachbox pendant. It provides the ability to guide the robot to accommodate slight variations in part position.

The latest in Wittmann’s mold-temperature-control units (TCUs) is the Tempro plus D120 Large, a high-end unit with new 5.7-in. color touchscreen, connector for a mold sensor, mold-purging function, and interface to Wittmann’s Flowcon plus flow controller and to the injection machine control. These interfaces and the ability to integrate the TCU control into the Unilog B8 control is an example of Wittmann’s version of Industry 4.0, which it calls Wittmann 4.0 (see April ’15 Keeping Up).

The new unit is a high-capacity direct-cooling, single-zone TCU with a 4-kW (5.4-hp) pump, capable of a maximum flow rate of 280 l/min (74 GPM) and max. pressure of 5.9 bar (86 psi), suiting it to molds with multiple cooling circuits. Heater capacity of 36 kW allows water temperatures up to 120 C (248 F).

Also new is dual flow-monitoring capability on Tempro plus D units. Ultrasonic flow measurement is available on two independent cooling circuits per zone, rather than just one. In addition, Wittmann’s Flowcon plus electronic, multichannel water-flow controller, which was introduced last year with its control integrated into the Unilog machine control, is now available in a stand-alone version with net8 control platform on a handheld touchscreen pendant.

Also new at the Vienna event was the G-Max 12 beside-the-press granulator, said to be “the first remote-controlled granulator.” It comes with a handheld pendant and 3-meter cable that allows control of a unit inside a guarded area without opening a safety gate and interrupting production. It can also communicate with the injection machine—for example, an optional special shutdown function turns the granulator off to save energy when the press is shut down.

The unit has a 1.5-kW (2-hp) motor, cutting-chamber dimensions of 7.8 x 6.7 in., and throughput capacity of 50-70 kg/hr (110-184 lb/hr). It is said to combine the cooling advantages of an open rotor with a staggered knife configuration that takes small bites, suiting it to thicker parts. It has a belt drive instead of gear-motor direct drive, so it is less susceptible to damage from sudden jams.

Also shown in Vienna was a prototype of the new MAS 4 HD, a 5.4-hp unit with 16.5 x 7.5 in. cutting chamber, suitable for up to 242 lb/hr. It has a standard three-knife rotor, plus new automatic belt tensioning for its drive.

Among the latest developments in materials handling are the Feedmax basic G203 and G206 vacuum receivers for central loading systems with 3- and 6-liter volumes, respectively, as well as the 15-liter Feedmax plus G315. The “basic” units have a lower-cost flapper discharge valve, while “plus” models have a positive-discharge bell. A new option is a slide gate, which enhances the material-line seal because it won’t jam on a pellet.

Wittmann’s new net5 TeachBox touchscreen control pendant allows central control of integral loaders as well as vacuum receivers. One TeachBox can handle 24 loaders and two pumps. When plugged into any one loader in a system, it provides visibility of all the loaders via CANbus communications.

Also new is the CS filter station for smaller systems. This economical system employs filter cartridges with cyclone separation. The filter requires mechanical cleaning, as there’s no blowback function.

New to the U.S. is the Codemax coupling station for distributing materials from multiple sources to multiple processing stations. RFID tags on the coupling cap won’t let an operator send the wrong material to the wrong machine. The RFID cards are now modular, making the system easily expandable.

Further developments in the Gravimax 14 gravimetric blender (176 lb/hr), which was shown in prototype at NPE 2015, were displayed in Vienna. A new optional static loader plate lets you remove a bin for a material change without dismantling the loader. The new OPC-UA "open," cross-platform communication protocol is optional for integrating the blender with ERP and MES systems.

An upgraded version of the Gravimax G56 blender, shown in prototype at Fakuma 2014, is a six-component model for up to 1760 lb/hr. Drain stubs and hinged windows for easy cleaning are both standard.

(For more Wittmann news and K preview, see Keeping Up section.)

Related Content

Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

Read MoreHow to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreThe Importance of Mass Balance in Chemical Recycling

Approaches to mass balance can dramatically impact calculations of recycled content.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More