In the early days of the pandemic, there was a specific moment when the speed and the breadth of the oncoming crisis became clear. While making a last-minute supermarket run to stock up before a threatened lockdown, I listened to the news in my car with updates on the virus’ early spread. Shopping complete and back in my vehicle, the station again announced the number of positive cases in my state, but it was double the figure I heard on may way to the store. I doubt if I had been shopping for more than 30 minutes. At this point, total cases where I live were still well below 100, but they wouldn’t be for long.

Tracking the figures as they grew became a grim habit, but, like rubbernecking a traffic accident, I couldn’t look away. So frequent were my visits that my web browser would autofill the addresses of the various virus-tracking sites after typing only a few letters of the URL.

In our psyches, coronavirus became all encompassing because it was all encompassing in the real world. I’m a stickler for the use of literally, so I don’t say this glibly, but COVID-19 literally affected every aspect of our lives over the last year—work, home, family, friends, politics, sports, you name it. As I write this, news reports still contain grim hospitalization and fatality figures, but they also contain hopeful numbers like vaccine efficacy and and total dose deliveries.

In that hopeful spirit with only days left in 2020, Plastics Technology’s editors are looking back and taking stock of COVID-19’s effects and potential lasting impact on our world. Not the negative consequences, but the positive ones.

So, in the never-let-a-good-crisis-go-to-waste sense, we’ll catalog 20 positive outcomes from the exhausting year that was 2020. As my editor, Jim Callari, wrote in his latest column for our January 2021 issue:

I’ve learned a lot about myself over the past year. I’m more flexible, adaptable, optimistic, and open to change then I ever thought I was before. Good things. But I’m ready to get back to the old normal.

Here’s to the “good things” of 2020 that will be part of a new normal.

Remote Control

At my very first NPE back in 2003, I remember visiting an auxiliary equipment supplier whose big news was the ability for users to remotely connect to equipment. This was not the first or the last time such connectivity was promoted, but the promise of remote access seems to have finally been fully realized in 2020. Processors who had never or rarely availed themselves of the capability, did so this year as travel restrictions precluded on-site visits from equipment suppliers.

This molder utilized ERP to keep production running from home, but others have used equipment connectivity for everything from training and maintenance to new machine startup and installation.

Automation Makes a Move

At the onset of the crisis when social distancing forced processors to minimize people on the plantfloor, automation was an obvious means to do so. As the pandemic progressed, and it became apparent that much of the personal protective equipment (PPE) and cleaning supplies in desperate demand were not made in the U.S., a renewed reshoring push brought some of this production stateside. To keep it here, many processors installed automation to boost their productivity and competitiveness. The extreme version results in lights-out production—No people? No social distancing challenges—which I highlighted at Medical Components of America and the Plastikos family of companies. The robotics industry reported record results in 2020, and I think those figures will only keep rising.

New Ways to Meet Up

As someone for whom travel has been an integral part of my professional life, whether it’s attending a conference or trade show or visiting a processor to tell their story with an in-person perspective, 2020 hasn’t been a banner year for my mileage. In fact, my only time on a plane—back in January—was actually for a personal trip to watch my daughter’s soccer tournament. For a while, events were simply canceled, moved or sometimes moved and then cancelled anyways. Then online platforms allowed for virtual events, including Plastics Technology’s own Tech Days series.

Is there Zoom, WebEx, GoTo Meeting and FaceTime fatigue? Definitely, and the first time a live event becomes a safe option, I have no doubt it will be extremely well attended, but I don’t think any of us will be uninstalling any of those programs any time soon, and that’s mostly positive. For me, the ability to occasionally attend a press event or technical conference remotely, without getting on a plane, is welcome change, especially if in the past the only option would have been skipping something entirely if I couldn’t make travel work.

Plastics’ Public Perception

Not very long ago, plastics were headed towards near-anathema status in public perception. Forget just banning bags or straws, all single-use plastics were in the cross hairs in many parts of the world. The backlash was not without cause, plastics pollution, and the need for better end-of-life-options are real issues that the industry is actively engaged with at all levels. In 2020, however, plastics ubiquity became a positive, whether it was in the face shields health care workers donned, take-out containers that kept restaurants afloat, or in the syringes that will deliver COVID-19 vaccines, plastics’ essential role to modern, hygienic life became clear. We have countless examples of plastics contribution in the pandemic, from face shields and test kits to syringes and face masks. PR work remains for the industry, but I think the general public might step back from the ban-all-plastics-forever brink.

Common Cause

Finally, the industry’s efforts to collaboratively respond to the pandemic were nothing short of inspiring. Facing a collective challenge, all segments of our industry asked what they could do to help and then set about doing those things. Consortiums formed, innovative solutions were found, weekend shifts were added, emergency production of new components was launched and so much more.

In our July issue, I highlighted MGS Manufacturing’s extraordinary response to the testing-kit demand the pandemic produced. Paul Manley, MGS’ president spoke about the pride his company’s efforts had engendered in him. “I’ve been a part of MGS for 24 years now,” Manley told me, “and truly, I’ve never been more proud to be a part of the organization than in the last couple of months, seeing how so many people have responded so admirably.”

Much of what the industry did in 2020 is more than admirable and worthy of prideful reflection as we head into 2021.

20 Good Things to Come Out of 2020—Part 2

20 Good Things to Come Out of 2020—Part 3

20 Good Things to Come Out of 2020—Part 4

20 Good Things to Come Out of 2020—Part 5

Making a list of 20 positive things to come out of 2020 isn’t as hard as you might think.

Read Next

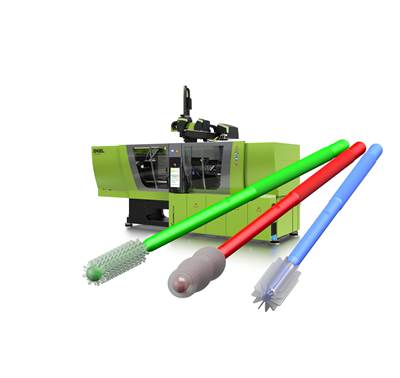

Covid-19 Test Swab Production Cell Introduced

Cell includes a mold, molding machine and robot with the ability to create 320 test swabs per minute and 460,000 test swabs per day.

Read MorePlastic Food Packaging and Sustainability During COVID-19

Bob Maughon, executive vice president, technology & innovation for SABIC, discusses the role of plastic food packaging and sustainability in light of today’s public health climate.

Read More3D Printing Providing Opportunities During COVID-19

A look at two companies working on 3D-printed PPE equipment.

Read More