20 Good Things to Come Out of 2020—Part 3

Processors and resin makers step up; biobased/renewable PP makes commercial strides; BOPE makes inroads as monolayer contender; and, performance PP for engineering applications & sustainability 'shines'.

Diverse Processors Step-Up for PPE

Through 2020, we saw so very many examples of plastic processors stepping up to meet the need for PPE and other hygienic and medical equipment. In the majority of cases on which we reported, these were not the type of products typically manufactured, and their production nearly always entailed some innovative equipment conversion and also collaboration with other manufacturers. Among my favorites were an automotive parts and packaging manufacturer and a global thermoformer that serves the medical, telecommunications, automotive, and electronic industries.

Resin Makers Do Their Part In Donating Resin

Resin makers faced their own host of challenges through 2020, ranging from labor shortages to unplanned feedstock and resin production shutdowns including weather-related disruptions. On one hand, this translated to higher prices for processors, particularly as we moved into the latter part of the year. On the other, several resins suppliers stepped up their efforts to help meet the need for PPE, and more often than not, this entailed the donation of resin. Among my favorites, was a group of ‘live-in mode’ resin supplier employees for whom their community did drive-bys to show their support! Others included collaborative efforts with manufacturers and industry institutes.

Roadway to Biobased/Renewable Feedstocks and Resins Widens

Just as mechanically and chemically recycled-content resins and compounds are here to stay and advance in quality, so to is the drive toward biobased/renewable feedstocks and resins, albeit more slowly. Some of the news we reported on in 2020 showed significant promise in terms of commercial realization. To me, the highlight was the commercial production of certified renewable polypropylene.

Also encouraging is support for bioplastics such as PHA from the government, and new patented bioplastics from universities looking for commercial partners for tougher more versatile medical implants.

BOPE Grows in Stature as Another Monomaterial Contender for BOPP & BOPET

Biaxially oriented polyethylene film technology (BOPE), whether based on LLDPE or HDPE, is making inroads as a recyclable monomaterial contender with multilayer BOPP or monolayer BOPET films. We first reported on this technology in the latter half of 2019, as we approached the 2019 K show in Düsseldorf. There, SABIC launched a new LLDPE for BOPE, showcasing standup pouched suitable for confectionary and snacks; frozen, fresh and dried fruit and vegetables; and packaging for personal-care products.

In 2020, we reported on a new HDPE for BOPE from Nova Chemicals and its collaboration with several organizations across the supply chain. The company sees HD-BOPE as having greater potential in that it’s more easily recyclable and can enable higher recycling rates for flexible packaging and help brand owners achieve their circular-economy commitments.

PP Moves Forward in Performance & Sustainability

As one materials/additives editor, it is difficult not to have some if not quite a bit of ‘affection’ for polypropylene. We have seen some very noteworthy advances in the PP arena over the years, ranging from clarified PP for packaging and consumer goods to reinforced PP compounds to recycled-content grades and now biobased grades.

So, it was a true pleasure to have some of the prominent players in the business weigh in for our September 2020 feature on how new performance PP is not only tackling ‘engineering’ applications but also the all-crucial sustainability issue.

Read Part 1, Part 2, Part 4 and Part 5 of 20 Good Things to Come Out of 2020.

Related Content

Best Practices for Purging PHA and PHA/PLA Blends

Because bioplastics are processed at lower temperatures, purging between jobs requires a different process and purging agents than those applied for traditional resins.

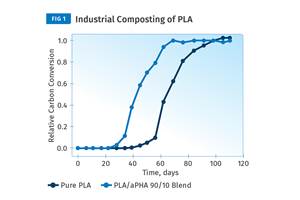

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreHonda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More