A Window of Opportunity Opens to One Million Parts a Day

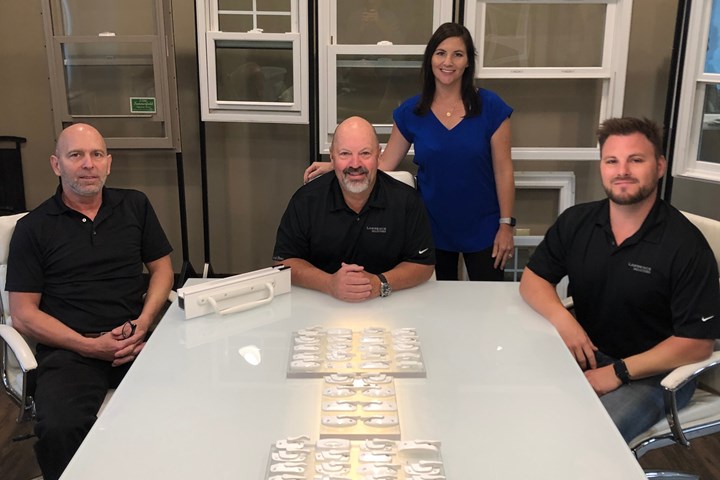

Injection molder and moldmaker Lawrence Industries was founded on the promise of plastics as a replacement for metal in window hardware—a market it now dominates.

Starting out in injection molding while he was still in college, with additional experience in metal stamping, die casting, finishing and moldmaking, Barry Lawrence spotted a new opportunity in the window hardware market shortly after exiting the space via the sale of a business he had helped found.

“About 20 years ago, when I was 40 years old, we sold out to the big guy in the industry,” Lawrence recalls. “They came through trying to consolidate the industry, buying everybody. They asked me what I wanted, and I threw a number at them.”

“If you want to launch a product line, we’re your guys. If you want to get it quick, we’re the guys. If you’re down and somebody can’t supply a part, we can get you out of the hole.”

For the next five years, Lawrence was out of the window business but he watched with interest as composite materials—glass- and fiber-filled plastics—were starting to emerge as a metal replacement for hardware or the latches, locks and handles that had always been a painted metal. “Then the wheels started turning,” Lawrence says. “’Wow! What if I had done this or this?’”

As those wheels turned, Lawrence and his brother witnessed much of the industry moving offshore. It was at this time, as shops shuttered, that Lawrence and his family bought back in, finding ready equipment sellers that let them snatch up soon-to-be-shut-down machinery. Buying a plant’s worth of equipment for what he estimated was $15,000, Lawrence and his brother set out to start a new business, Lawrence Industries, in Thomasville, N.C. “We spent about six months developing products; making prototypes; building prototype molds; realizing what didn’t work; and going back to the drawing board,” Lawrence says. “So, a lot of sweat equity, but we finally developed a product that we could bring to market.”

Vertical Integration; Heightened Flexibility

Even back when he worked in metal hardware, Lawrence saw the value of vertically integrating capabilities, investing in tooling and equipment to make metal parts, starting in stamping, moving into painting, and eventually into die casting. Then a change in the market presented an opportunity.

“Back when the early development of vinyl windows was starting,” Lawrence says, “there was a whole new series of hardware that came out.” His company was involved in helping develop those lines, winning more business on the basis of speed. At that time, in the mid ’80s, Lawrence remembers lead times of 26 weeks or more. Through lean manufacturing and vertical integration, including moldmaking, his company was able to trim that all the way down to just two weeks. “We were able to come up with systems that allowed customers to buy the quantities they needed,” Lawrence says, “It wasn’t necessarily JIT (just in time), but it was close.”

Making the Best Blend

Much of the Lawrence Industries’ development work centered on achieving the right blend of color, resin and filler to achieve the fit, finish and strength required in window hardware that had been dominated by metal. The company eventually developed its own special blend that was able to pass all the requisite qualifications, including the most stringent trial, the hurricane test.

Part of the company’s appeal is the ability to sell all the kinds of hardware for a window project, matching color on the various components, since it’s making them all, but tailoring their mechanical properties to suit their role in the window. Filling nylon with zero to 50% glass fiber, Lawrence often blends already mixed resins for the perfect match. “Some parts work better with less fiber, and some parts work better with more,” Lawrence says. “We have parts with five components and they’re all different percentages.”

About 90% of those products are white, and that poses a unique challenge. “White is the most complicated color there is,” Lawrence says, “because it can vary with heat; moisture can have an effect on it; and the base resin can have an effect on it.”

To overcome the variations it can’t control, Lawrence works to standardize as much as it can, including material, color and machine sourcing. A Battenfeld machine was among the bargain presses Lawrence bought back when picking through the auctioned remains of offshored plants. The machine worked well, and while Wittmann Battenfeld offered support while it still ran, Lawrence planned a production bridge to the future. “I said, ‘Look, if you support us now, we’re very loyal; we want to keep as many machines the same so that our people don’t have to learn different operations,” Lawrence says. The company obliged and now Wittmann Battenfeld presses make up its entire 40-machine fleet. “We find their machines very user-friendly, very consistent, and the parts are interchangeable between different platforms,” Lawrence says. “Our guys know them inside and out.”

Today, Lawrence Industries is the biggest consumer of nylon on the East Coast, molding around 1 million parts/day, pumping out three times the volume of production with one-third the employees it formerly had thanks to automation and efficiency gains. Their current 60,000-ft2 plant and 60 employees will soon be joined by a new 15,000-ft2 warehouse.

“If you want to launch a product line, we’re your guys,” Lawrence says. “If you want to get it quick, we’re the guys. If you’re down and somebody can’t supply a part, we can get you out of the hole.”

After buying an older Battenfeld at auction when it started its business, Lawrence Industries converted its entire 40-machine fleet to Wittmann Battenfeld presses due to their reliability and for familiarity to the plant’s operators.

Related Content

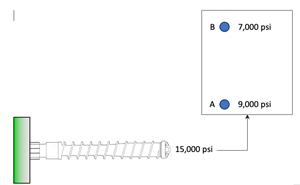

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreHow to Reduce Sinks in Injection Molding

Modifications to the common core pin can be a simple solution, but don’t expect all resins to behave the same. Gas assist is also worth a try.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More