ADG Solutions showcases new self-cleaning screen changers

At NPE2015, ADG Solutions is featuring its Fimic APR 500, which is a continuous, self-cleaning screen changer that has new control programming, as well as a 6” Davis-Standard ram stuffer. Also featured at the booth are separation and washing systems from Tecnofer, shredders from Weima America and densification systems from Promeco SpA.

Sandy Guthrie, founder and president of ADG Solutions, notices a big change from three years ago at NPE2012.

“There is much more awareness of reclaim,” he told Plastics Technology at NPE2015 (W-6754). “Compared to three years ago—even a year ago—it’s a much stronger year.”

At NPE2015, the company is featuring its Fimic APR 500, which is a continuous, self-cleaning screen changer that has new control programming as well as a 6” Davis-Standard ram stuffer. Also featured at the booth are separation and washing systems from Tecnofer, shredders from Weima America and densification systems from Promeco SpA. ADGS also announced the first installation of a Promeco system in North America.

“We are presenting NPE visitors with new and innovative approaches to reclaiming plastics scrap,” Guthrie said. “It doesn’t matter if it is post-industrial, post-commercial or post-consumer, plastic waste is valuable and it becomes more valuable when you process it correctly.”

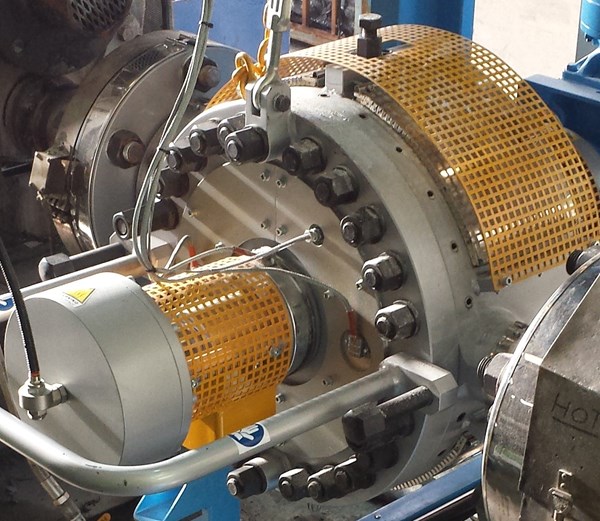

The Fimic model APR 500 continuous, self-cleaning screen changers, with new control programming, are ideal for contaminated reclaim extrusion streams. In operation, the melt-filtration unit is positioned at the extruder outlet so that it retains contaminates as small as 150 microns. As contamination builds up on the upstream side of the screen, inlet pressure increases to set point (set on the pressure control), triggering a scraper that removes contamination from the face of the screen filter.

The new Fimic units store the contaminants from up to six scrapings and discharge all the accumulated contamination at once. This system can cut the amount of resin wasted in the cleaning process by half or even two-thirds.

In addition, the new laser-cut screen plates that ensures extremely long life. With a large open area, back pressure is minimized, even at such fine filtration levels. A continuous-scraping mode is available to prevent pressure instability by immediately removing contaminants that can quickly blind the screen.

Ram stuffers, similar to the Davis-Standard unit display in the ADG booth, can be added to an extruder to handle a wide variety of plastic feedstock sizes and types. The super-size feed throat maximizes in-feed for consistently high extruder output even when processing low-bulk-density scrap material including fractional-gauge films.