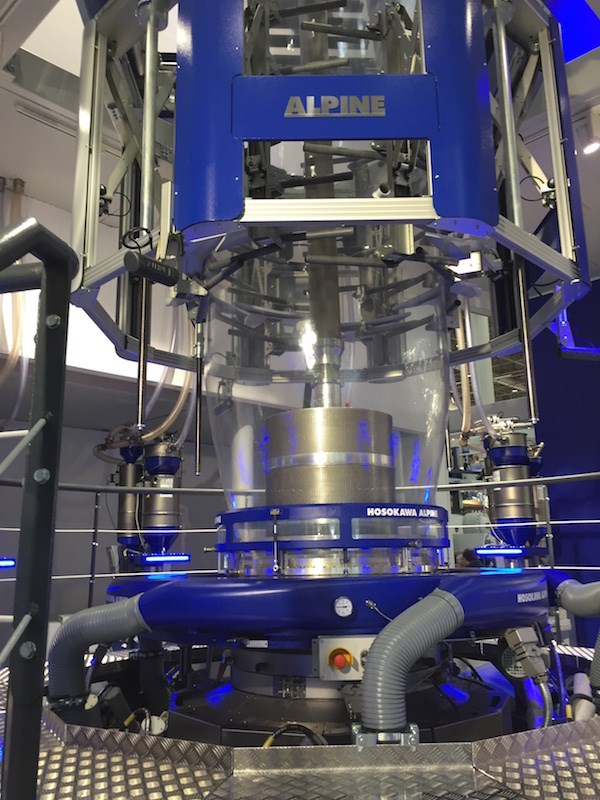

Alpine Kicks Off K With Lots of Layers

Layers are great with chocolate cake. And blown film too. Hosokawa Alpine ran what’s believed to be a show first: an 11-layer line producing nylon-based barrier film.

Layers are great with chocolate cake. And blown film too. Hosokawa Alpine ran what’s believed to be a show first: an 11-layer line producing nylon-based barrier film.

Over the past few K Shows most suppliers have stuck with five-layer structures. Back in 1998, Battenfeld Gloucester, now part of Davis-Standard, ran a seven-layer nylon-barrier blown film line at K. At K 2010, Reifenhauser ran a nine-layer line. The system Alpine fired up on Day One of K 2016 featured 11, grooved-feed 65-mm, 32:1 L:D water-cooled extruders and a 560-mm X Die, as well as a new version of its V air ring designed to maximize output.

It was equipped with a film-stretching unit built into the nip. The line offers “infinite flexibility by allowing processors to bundle 11 equal layers” in the configuration of their choosing, says Dave Nunes, president of the company, whose U.S. operation, Hosokawa Alpine American, is based in Natick, Mass.

Related Content

-

Single vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

-

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.