APR: Plastic Cans With Metal Lids Contaminate Recycling

Recycling association says new container design can lead to significant issues in the plastics recycling stream.

Recycling association says new container design can lead to significant issues in the plastics recycling stream.

Editor's note: the original blog article inaccurately mentioned both the Klear Can (developed originally by Kortec, which was acquired by Milacron) and TruVue clear plastic can developed by global packaging company Sonoco, Hartsville, S.C. as part of this story. However, the APR news release is referring to a "PET can with a metal lid that contaminates the PET recycling stream," and those manufacturers recyclability claims. Plastics Technology apologizes for this error.

A clear plastic can with a metal lid is an interesting new packaging innovation, but The Association of Plastic Recyclers (APR)—the international trade organization representing the plastics recycling industry—said that the containers could contaminate the PET recycling stream. APR went as far as urging caution to those companies considering the use of plastic cans.

“There is a reason Maine, Illinois, and Minnesota imposed restrictions or bans on this type of packaging,” said Steve Alexander, Executive Director of APR, in a news release. “A plastic can with a metal lid is a contaminant to PET recycling and not compatible with today’s material recovery and plastics reclamation systems.” According to APR, the state restrictions were imposed in response to production of plastic cans in the 1980s and their negative impact on the recycling process. These laws remain in effect today.

Although the PET portion of the can may be recyclable, the metal lid is seamed onto the PET. Currently, there are no practical solutions to separate the two components in material recovery facilities (MRFs), rendering the entire container non-recyclable, argues APR.

“APR has already reached out to companies producing plastic cans to voice the concerns of the plastic recycling industry,” said Byron Geiger, President of Custom Polymers PET and Chairman of the APR PET Technical Committee. “Brand companies consistently require suppliers to provide evidence of compatibility with recycling. The APR works with companies to ensure this is possible, and offered this support in communication with plastic can manufacturers.”

The APR has created laboratory test methods used to assess the impact of new innovations to the recycling market as an integral part of The APR Champions for Change program. Companies use these tests to confirm their innovations do not interfere with recycling. Once testing requirements are met, those companies receive APR Critical Guidance Recognition. This process addresses the challenge of introducing packaging that is consistent with recycling technology, and the APR encourages plastic can producers’ participation.

Additional information about metal components or attachments on PET containers is detailed in The APR Design Guide for Plastics Recyclability. The goal of the APR Design Guide is to have packaging designed that is compatible with the recycling infrastructure.

“As the voice of plastics recycling, APR strives to solve industry challenges,” commented John Standish, APR Technical Director. “Because the plastic can is a significant contaminant to the plastic recycling stream, we encourage its producers to collaborate with APR to design packaging that is recyclable and sustainable.”

Pictured: Polish packaging maker Invento's PET cans with aluminum ends.

Related Content

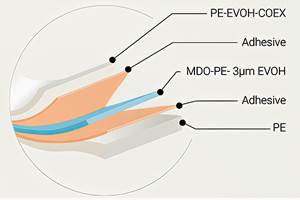

Foam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreRecycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

Read MorePlastic Bank Marks 10 Years and 88,000 Tons of Plastic Waste Reclaimed

Company sets up local exchange centers to divert plastic waste otherwise likely to end up in the ocean.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More