Coronavirus Spurs Nonprofit Startup to Develop World's First Compostable N95 PLA Masks

THRIVE Masks aims to produce meltblown PLA masks in the U.S. through Kickstarter campaign.

As we approached the end of March, the first month for most of us across the country practicing social distancing and essentially finding ourselves living in quite a different world, PT and its Gardner Business Media trade manufacturing news ‘siblings’ have been reporting on how our industries are faring with several notable examples of how companies are stepping up to help in the Coronavirus battle.

One of those articles resulted in my being contacted by Dakota Bass, an engineer, inventor, and entrepreneur with years of experience designing and implementing manufacturing solutions for many of the world’s most successful products. His message: “Would you be interested in reporting on our mask startup which is looking to swap meltblown PP respirator filters to meltblown compostable PLA?” Naturally, not only is this of interest right now but something I believe is certainly worth pursuing for the long run. Despite the recyclability advantages of PP products ranging from single-use food-related containers to automotive components, N95 certified PP masks are hazardous once used and as such cannot be recycled. The compostability of PLA masks, with equal efficiency, durability and certification is a big plus to consider.

Bass tells me that he and his San Francisco Bay area team of supply base engineers Matthew Moore and Emily Blaker, with experience in high-volume manufacturing (e.g., Ford, SpaceX), are starting a nonprofit startup company, THRIVE Masks, to boost mask manufacturing in the U.S. “We don’t have enough mask-manufacturing capacity here in the United States. It’s scary in times like this to be reliant on other countries for medical equipment and supplies. I want to build a mask factory here so that we can protect our healthcare workers and citizens now, and be better prepared in the future if something like this happens again.”

Thus far, the company, has had success in working with two Chinese manufacturing partners outside of Shanghai that both produced meltblown PP N95 masks for the team, which the team has donated to hospitals, but more crucially, produced a number of mask models made out of meltblown PLA.

According to Bass, the THRIVE Masks are engineered for at least 95%* filtration efficiency against certain non-oil based particles, making them the perfect option to people from harmful airborne pathogens like bacteria and viruses. Different from other masks on the market, THRIVE masks are designed to maximize comfort and safety by utilizing four separate layers of electrostatically charged spun-bonded filter material, ultrasonic welded construction, and an innovative wiper seal for less leakage and easy fit. Bass noted that that THRIVE masks are equipped with 5-mil wide straps made out of PLA produced by a German company with which the team has contracted.

KYD Automation Fabric Feeder.

The team launched its Kickstarter Page on Monday, March 30 (https://www.kickstarter.com/projects/thrivemasks/thrive-masks-worlds-first-compostable-n95-type-respirator), to accept direct donations through gofundme for the manufacture of compostable PLA masks, which the THRIVE Masks team will fund through preorders. “If the Kickstarter campaign is a success, we will order the automated equipment. Our aspiration is that we could start production of the masks in 90 days,” says Bass. He noted that NIOSH N95 certifications which they are aiming to complete, will be forthcoming once production commences. The company is also accepting donations if N95 PP masks for direct donation to healthworkers.

Related Content

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

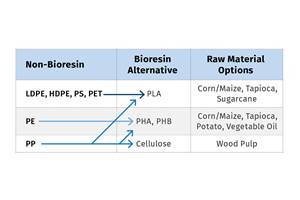

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

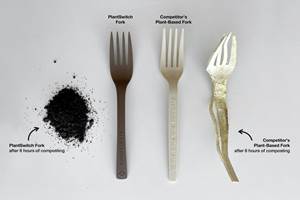

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More