Enhancing 3D Printing with Machine Vision and AI

Wojciech Matusik, co-founder and Chief Technology Officer of Inkbit, talks about the company’s technology and key additive manufacturing trends.

Inkbit is a 3D printing company to put on your radar. The company built the first 3D printer driven by vision-based feedback control. In February, the company launched Inkbit Vista, a new additive manufacturing system that features a platform based on scalable inkjet deposition and 3D machine vision.

Inkbit Vista features the proprietary vision-controlled Jetting solution and multi-material design software, enabling manufacturers to bridge the gap between prototyping and full-scale production.

I recently chatted with Wojciech Matusik, co-founder and Chief Technology Officer of Inkbit, to learn more about the company, additive manufacturing trends and the shift from prototyping to end-use production this year.

Can you give me background on Inkbit? How does Inkbit stand apart from other 3D printing companies?

We spun Inkbit out of MIT in the Summer of 2017, with the premise of giving 3D printers eyes and a brain. Since then, we have expanded our team and our vision—to create an additive manufacturing system that fundamentally changes the way that products can be designed and made. Our team has grown to 28, working out of our office in Medford, with the dream of building the factories of the future.

What’s the basis of vision-based feedback control? How does it help bridge the gap between prototyping and full-scale production?

Right now, the freedom of 3D printing cannot be translated into full-scale production—the precision is too low, the throughput is too small, and the post processing is too time consuming. We are able to create solutions to all of that with our proprietary Vision-Controlled Jetting (VCJ) solution and multi-material design software, enabling manufacturers to bridge the gap between prototyping and full-scale production. Inkbit Vista’s VCJ system brings eyes and brains to the 3D printing technology space, allowing real-time corrections and impeccable precision.

The intelligence of our machine allows us to match the reliability and performance demands of volume manufacturing. This technology converges advanced computational techniques with a scalable hardware architecture and materials chemistries inaccessible to incumbents.

Can you detail the company’s partnership with the United States Air Force?

This February, we were awarded a Small Business Innovation Research (SBIR) contract for $1.7 million from the United States Air Force to build three Inkbit systems for use at USAF bases across the country. These three systems are among the first commercial systems to be built by our company. These machines will allow the USAF to have the freedom to design when and where they want, creating end-use parts that can pass quality standards and reduce general production costs.

What are some of the biggest trends you see in digital manufacturing?

The biggest trend in digital manufacturing is an automation of the design and manufacturing processes. We believe that product R&D will be much simpler compared to how it is done currently. It will be much closer to how software is developed today. Novel multi-material products will be developed digitally and optimized to achieve the best performance. Designers and engineers will be able to prototype these products on multi-material additive systems in a matter of hours and then use the same systems to scale production to thousands or even millions of units. Overall, it will be much easier and much less expensive to release new products to the market.

What do you foresee for the future of materials in AM?

Overall, we think that there will be more and more materials that are developed for AM processes. Today, the set of materials available for AM is very limited. For example, the materials used for SLA, DLP, or inkjet deposition processes are all acrylates or acrylate mixtures. This severely limits the range of material properties and the scope of applications that can be addressed by these processes. In contrast, Inkbit Vista’s VCJ processes allows working with a much wider range of materials. For example, our pure epoxy resins have very good chemical resistance that are required for many commercial applications.

Will there be more of a shift from prototyping to end-use production this year?

For us at Inkbit, we see that the current industry of 3D printing revolves around prototypes and parts. With Inkbit Vista, we print products. Our materials, technology, and easy post processing allow us to create fully assembled products that would take complex assembly processes with more conventional manufacturing methods. We are excited to enable designers to have unlimited creativity and geometric freedom—unlocking innovation in every industry.

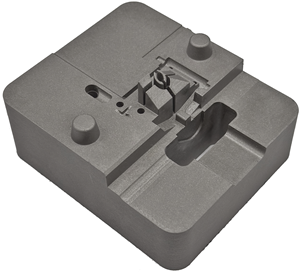

Inkbit Vista 3D Printer.

Related Content

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

Read MoreProduction Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreRead Next

Additive Manufacturing System Reportedly Revolutionizes 3D Printing

The Inkbit Additive Manufacturing system is said to feature first-of-its-kind closed-loop feedback control, multi-material printing capabilities, and exceptionally-low cost-per-part for final part.

Read MoreKey Additive Manufacturing Trends to Watch in 2021

EOS, HP, Carbon and Essentium give a preview of what to expect from additive manufacturing in 2021.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More