Essentium to Debut HSE 280i HT 3D Printer at Rapid + TCT 2021

This industrial-level 3D printing system features independent dual extruders (IDEX).

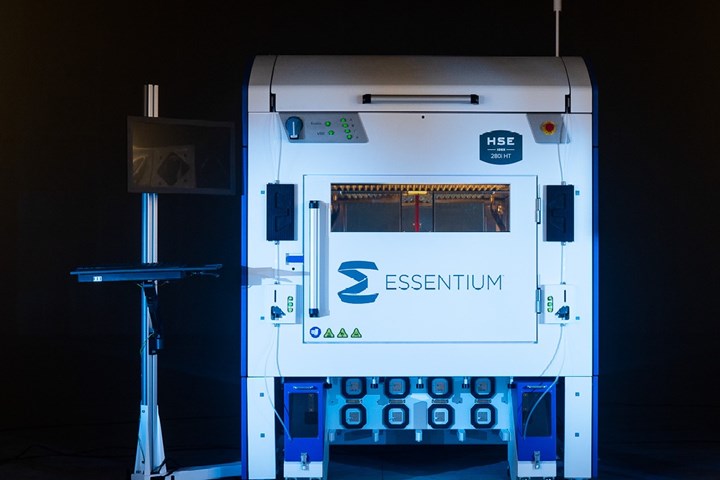

Essentium will make the first public demonstration of the Essentium High Speed Extrusion (HSE) 280i HT 3D printer at Rapid + TCT (Sept. 13-15; McCormick Place, Chicago, IL). This industrial-level 3D printing system features independent dual extruders (IDEX). A reported first-of-its-kind, this IDEX system is independent on both the Y and X axis, enabling manufacturers to 3D print multi-part builds at industrial speeds, even for parts with complex geometries.

According to a recently commissioned third-party study from Essentium, the majority (84%) of respondents feel that companies who invest in AM will have a clear competitive advantage in the next five years. However, 20% of executives report that industrial-scale 3D printing hardware is too expensive, and 37% are held back by the high cost of 3D printing material.

The HSE 280i HT reportedly addresses these obstacles by delivering large build volume, high-throughput production capabilities, and high-temperature material compatibility. For industrial-scale manufacturers in aerospace, electronics, automotive, and consumer goods, the HSE 280i HT provides functional prototyping and full-scale production using high-performance engineering filaments.

Five different build modes come standard with the 3D printer: single head mode, support mode, multi-process mode, copy mode, and independent mode. The HSE 280i HT is equipped with a non-slip, high torque extrusion system and linear servo motors.

Essentium’s research found that 96% of manufacturers want open ecosystems to give them more control. The HSE 280i HT can print with materials from Essentium’s materials portfolio, such as PEEK, TPU, and nylon, as well as materials from other companies. As an open-material printer, the HSE 280i HT offers application flexibility and room to grow.

Essentium announces the HSE 280i HT will debut at Rapid + TCT.

Related Content

-

3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).