Farrel Pomini Debuts New HQ For Continuous Compounding

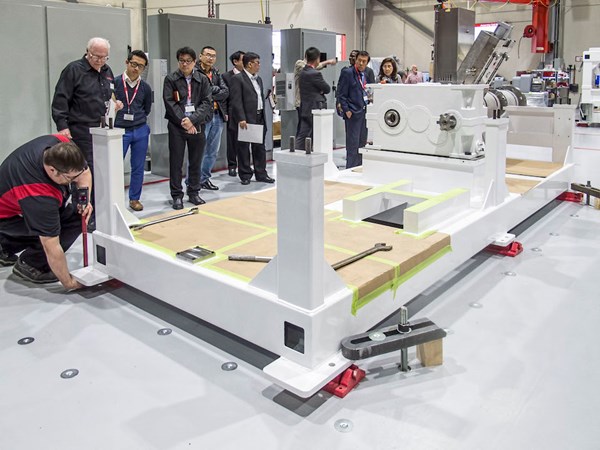

More than 50 visitors were given a tour of Farrel Pomini's new headquarters for continuous compounding systems in Ansonia, Conn.

On a breezy hilltop with a clear view down to the sprawling old mill on the Naugatuck River that had been its home since 1848, Farrel Pomini now occupies handsome new headquarters and assembly plant in Ansonia, Conn. Although the official ribbon cutting was last month, the firm’s 86 employees actually moved into the 60,000-ft2 facility last September. “It’s the first time in 100-plus years that all U.S. Farrel people are under one roof,” said Paul Lloyd, the business unit director, FARREL POMINI.

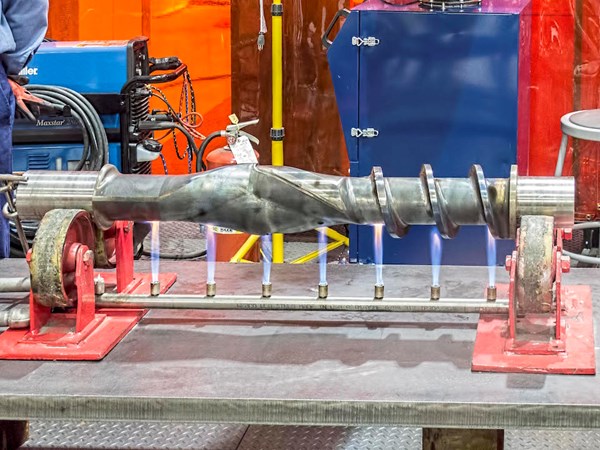

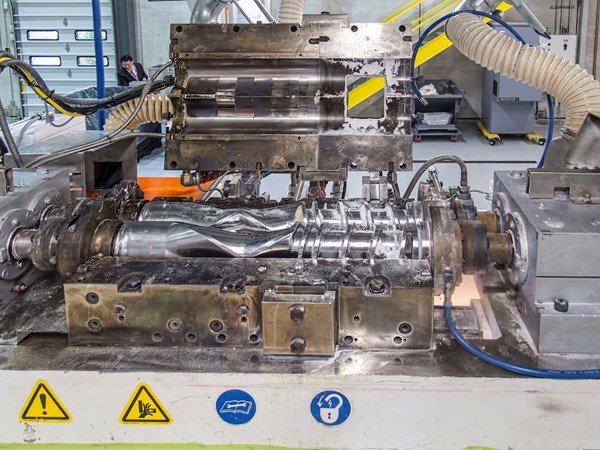

More than 50 visitors were given a tour of the new headquarters for continuous compounding systems based on Continuous Mixers and Compact Processors. It incorporates offices, machine assembly, spare-parts stocking, rotor repair and refurbishment, and a processing laboratory and customer demonstration area with a CP550 Compact Processor equipped with automated upstream materials handling and downstream pelletizing, plus the new CPeX lab-sized Compact Processor that was introduced at K 2016.

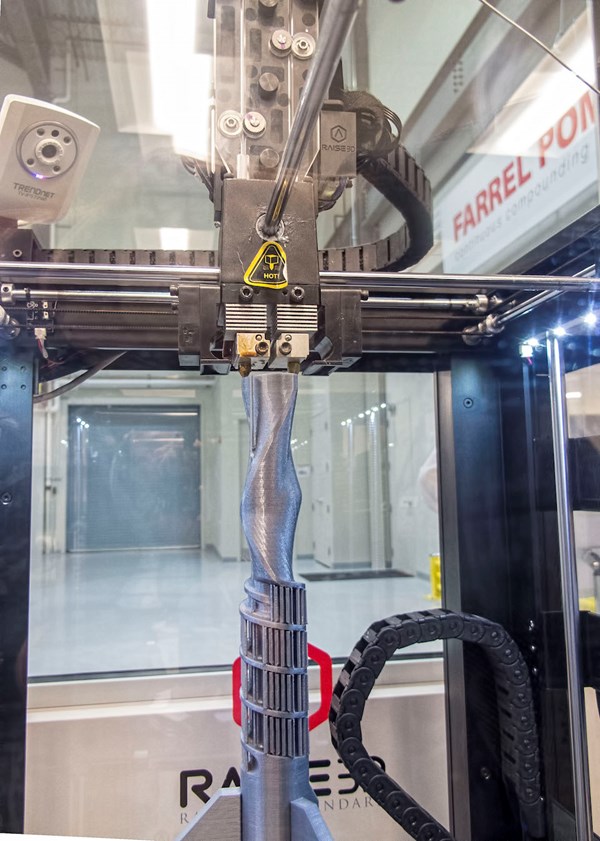

The facility also includes an R&D department with a 3D printer for prototyping scaled-down rotors and other machine components, and also an automation laboratory for designing and testing control systems for compounding process lines.

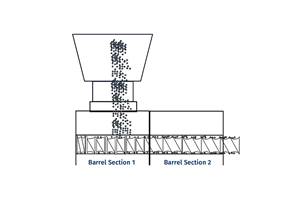

Lloyd reported that his business unit has enjoyed 15-20% annual growth, supplying continuous compounding equipment for flexible PVC, polyolefins, and TPEs. A promising new area of opportunity, he added, is biopolymers such as PLA, which require gentle handling due to their heat and shear sensitivity. The Compact Processor, which consists of a Continuous Mixer with twin “wing-type” rotors mounted over a short single-screw discharge extruder, is well suited to PLA, said Lloyd, because its large open feed area allows for high levels of fillers and additives; its short 6:1 L/D minimizes the heat history, and its design separates mixing and pressurizing functions, so mixing can be optimized while still providing a shorter residence time than a twin-screw extruder.

Farrel Pomini business unit director Paul Lloyd announcing the official opening May 4th of the company’s new headquarters in Ansonia, Conn.

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreHow to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

Read MoreSafety, Recycling, and Compounding Trends Bring New Opportunity to 70-Year-Old Company

NPE2024: Vac-U-Max presents pneumatic conveying solutions for powdered materials.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More