Fibers Pair With Foam for High-Bending Stiffness at Low Surface Weight

Reduced clamp force, shorter cycles, lower melt viscosity, and higher dimensional stability are just some of the purported benefits of foam injection molding.

Marcel Holzner, research engineer at the Fraunhofer Project Centre for Composites Research at Western University in London, Ont. will address those benefits and offer more details on the promising technology during a presentation at Molding 2015 (June 16-18, Donald E. Stephens Convention Center, Rosemont, Ill.).

In foam injection molding, a blowing agent is added to the melt during plastification, causing the material to expand due to a pressure drop during injection, according to Holzner. In addition to the previously mentioned benefits, the process also reportedly reduces part density while imparting high specific bending stiffness. When fiber-reinforced materials are used, Holzner notes that the reduced melt viscosity of gas-loaded thermoplastics leads to fiber preservation, adding that when it comes to preserving fibers, ultimately there are many parameters that influence fiber length.

The technology applies what’s called a “breathing mold,” which Holzner explains is synonymous with technologies like core back injection molding, negative embossing, foaming with decompression and precision mold opening. “With this foaming technique—a high-pressure process—the cavity is filled completely,” Holzner explains. “After a short packing pressure and delay time, the mold opening stroke can be launched to a defined part thickness. Additional venting is not necessary but molding techniques like gas counter pressure injection can assist to improve surface quality of foamed parts.”

The process differs from structural foam molding in that with structural foam molding, continuous fibers and polymer are utilized, with plasticizing and injection as discrete process steps that require an extruder, melt buffer and injection unit. In foam injection molding (FIM), long fiber granulates are used as feed material.

At the Fraunhofer Project Centre, the researchers have two different injection units available for testing: standard and MuCell. Holzner says that to achieve long fiber integral foams, LFT granulates can be used in combination with chemical (masterbatch) or physical blowing agents (MuCell super critical fluid). “The use of long fiber optimized screws maintains the use of LFT granulates and the low shear screw design preserve fiber length,” Holzner says. For FIM, precompounded long-fiber pellets with fiber lengths up to 12 mm are used

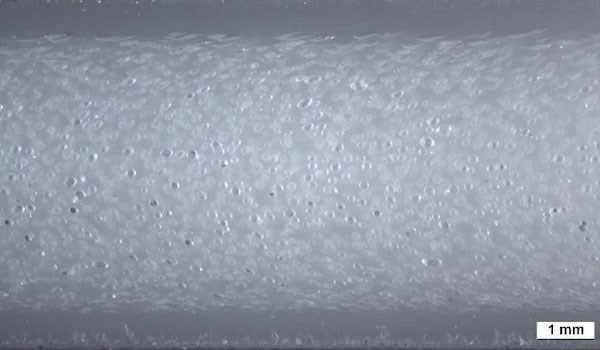

The integral foam structure, featuring a compact skin layers and foamed core, is promising for automotive applications like door panels, seat shells, underbody assemblies and instrument panel support thanks to the resulting high bending stiffness at low surface weight.

In terms of surface finish, Holzner says FIM parts exhibit reduced warpage and sink marks, but they can show flow marks. To overcome this, the researchers noted that gas counter pressure could be applied. The appeal to automotive is the combination of lower weight and strength. “With breathing mold technology, up to 20% to 30% further light weighting is considered realistic,” Holzner says. “Keywords are density reduction and thin wall injection molding.”

To learn more about Molding 2015, visit the event’s website where you can view the full agenda and register.

Related Content

-

Prices for All Volume Resins Head Down at End of 2023

Flat-to-downward trajectory for at least this month.

-

Prices of All Five Commodity Plastics On the Way Up

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.