Five Ways SPC Can Improve Performance

Statistical process control (SPC) can help plastics processors determine the factors responsible for product quality variation and provide a roadmap for improving the production process.

Successful plastics manufacturers and molders have mastered the ability to compete on quality while reducing the inefficiencies and scrap that can create a drag on profitability. For many of these companies, statistical process control (SPC) serves as the framework for continually finding new ways to improve process control, process performance and product quality.

Fundamentally, SPC enables manufacturers to inspect a random output sample from any measurable process and understand what is causing deterministic variations in product, process and quality levels that can be modeled versus completely random factors. This empowers managers to decide whether a given process is producing products with characteristics that fall in a predetermined range. For plastics companies, SPC has proven highly valuable for analyzing deviations in process parameters, temperature, velocity, and machinery attributes that can cause higher scrap rates.

The insights generated from periodic SPC analyses of production data then enable manufacturers to model the deterministic factors responsible for product quality variation and provide a roadmap for improving the production process factors that lead to the delivery of consistently higher quality products.

Let’s look closer at how manufacturers in the plastics industry use SPC to establish consistency, improve performance, facilitate compliance, manage quality, and improve financial performance.

Establish Consistency

One of the most valuable outcomes of SPC is establishing and maintaining consistency in each process and finding new insights that lead to continuous process improvement. SPC doesn't eliminate variation, but it allows us to track special cause variation.

Two forms of SPC statistics that support these efforts are acceptance sampling and descriptive statistics. Acceptance sampling—where runs from plastics molding machines and production processes are randomly sampled—helps managers to decide whether or not to accept an entire lot based on the results. Meanwhile, descriptive statistics are used to describe the quality characteristics and relationships of finished goods. Statistical analysis of these factors enables quality engineers to quantify and understand which factors most influence a production process' capacity to consistently produce excellent product quality.

Improve Performance

Two types of charts serve as key tools for SPC that plastics manufacturers and molders regularly rely on to improve their performance. Run charts plot a single line for a particular value over time. More sophisticated control charts plot the data being calculated along both upper and lower control limit lines over time, with a center line for context. The added context helps managers answer more questions about the processes they track.

SPC doesn't eliminate variation, but it allows us to track special cause variation.

By combining run charts or control charts with time series analysis, manufacturers can track the evolution—or the lack of evolution—of the underlying distribution of data based on production results. The insights derived from these analyses enable managers to make more informed, data-driven decisions about refining their processes to improve performance.

Facilitate Compliance

SPC helps manufacturers in the plastics industry to comply with customer and regulatory requirements. Companies typically start by measuring and plotting the output of a process. This is followed by looking for signs of non-random behavior, identifying the underlying cause and eliminating it. Once this is accomplished, SPC is used for monitoring the process to further minimize normal random variation and ensure that processes remain within the required parameters for compliance.

For example, a leading medical plastics packaging manufacturer relies extensively on SPC for ensuring compliance with a range of industry and government standards. These include compliance with Current Good Manufacturing Practice (cGMP) regulations enforced by the United States Food and Drug Administration (FDA) and European Economic Area (EAA) requirements for CE mark certification for specific products, among others.

Manage Quality

Manufacturers in the plastics industry often get started with SPC because it is one of the truest measures of process and product quality, and it has proven valuable for supporting audits. SPC techniques are useful for measuring the value of a quality characteristic and helping identify change or variation in the quality of either the product or process. SPC doesn't eliminate variation; instead, it makes it possible to track special cause variation.

For instance, one of the leading plastics extrusion manufacturers relies on SPC to assist with quality assurance and enable the quality management team to perform an audit any time a customer or regulatory agency requests one. This company’s ERP system has all the product genealogy available in real time, and by combining SPC with the ERP system, the team has gained an entirely new level of visibility and control over every aspect of quality. Now, the team can deliver calibration certificates with orders, have complete auditing and control of all production records and process workflows, maintain tighter controls on work order instructions, and have SPC data to the machine level reviewable anytime.

Improve Financial Performance

Using SPC to understand whether a variation in production processes is either deterministic or random has immediate impacts on production costs, margins, and profitability. For plastics manufacturers, deterministic variations are a top priority, since these represent opportunities to implement process improvements. SPC can be used to quickly isolate which factors are deterministic and clarify the true state of performance for a given process.

Specifically, SPC provides plastics manufacturers with three major benefits as they look for ways to improve manufacturing performance. First, they gain greater clarity regarding the end-to-end production process by comparing deterministic versus random-based sources of variation. Second, once SPC becomes engrained into a company’s daily reporting, process control becomes more automated and easier to accomplish.

Third, SPC becomes a system of record over time for plastics manufacturers and molders, who make it a core part of their reporting system. The resulting SPC data over years of production runs help to troubleshoot potential quality and process bottlenecks that may occur on new products with a similar series of attributes of previous-generation ones.

Reading the Clues

The continual stream of real-time process and product data that plastics manufacturers and molders generate as a by-product of their production processes holds clues into how quality can be improved. With its inherent ability to differentiate between truly random and deterministic variables, SPC is the ideal statistical framework for aggregating, analyzing and identifying the reasons why process and product quality vary so widely in a given scenario. The most successful manufacturers in the plastics industry are leveraging SPC to provide a roadmap for continually enhancing their processes, optimizing operational efficiency, and maintaining consistent, high quality across their products.

About the author: Louis Columbus is currently serving as Principal of DELMIAworks (formerly IQMS). Previous positions include product management at Ingram Cloud, product marketing at iBASEt, Plex Systems, senior analyst at AMR Research (now Gartner), marketing and business development at Cincom Systems, Ingram Micro, a SaaS start-up and at hardware companies. Louis teaches MBA courses in international business, global competitive strategies, international market research, and capstone courses in strategic planning and market research. Mr. Columbus has taught at California State University, Fullerton: University of California, Irvine; Marymount University, and Webster University.

Related Content

Is There a More Accurate Means to Calculate Tonnage?

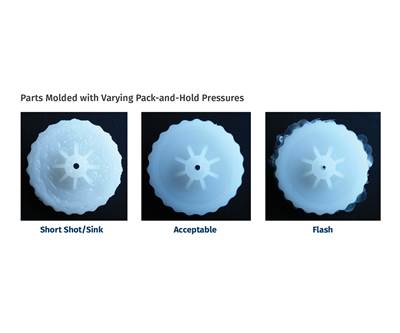

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

Read MoreThe Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreRead Next

Go Beyond SPC For Molding Process Control

A new real-time statistical analysis system for injection molding reportedly provides a new level of fault detection and process quality.

Read MoreThe Cosmetic Process Window: Key to a No-Tweak, Robust Process

Establishing a process with the widest possible cosmetic window can help put your injection molding on cruise control.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More