Lamborghini Expands Additive Manufacturing Partnership with Carbon

This new collaboration to produce 3D-printed air vents marks a significant milestone in Lamborghini’s partnership with Carbon.

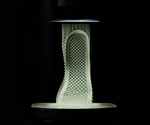

Interior design with digitally manufactured EPX 82 parts.

Earlier this year, Carbon and Lamborghini announced a partnership to digitally manufacture production parts. The companies have expanded this partnership and Carbon will now digitally manufacture both the central and lateral dashboard air vents for the Sián FKP 37, Lamborghini’s first hybrid production car. Earlier this year, Carbon and Lamborghini produced a new textured fuel cap and a clip component for an air duct for Lamborghini’s Super SUV, the Urus model. This new collaboration to produce 3D-printed air vents marks a significant milestone in Lamborghini’s partnership with Carbon.

For the Sián FKP 37, Carbon Digital Light Synthesis (DLS) technology combined with Lamborghini’s design and craftsmanship resulted in these new air vents.

Lamborghini Sián FKP 37 central air vent.

With the Sián air vents, Lamborghini reduced its part lead time by 12 weeks by moving swiftly from design to production directly on the Carbon platform. Time-consuming and costly tooling steps involved with traditional manufacturing were eliminated completely. Additionally, Carbon EPX 82 material was selected for the air vents given Lamborghini’s high standards for all car components. EPX 82 passed tests related to Interiors Flammability, Volatile Organic Compounds, Thermal Cycling and Heat Aging.

“With the Carbon Digital Manufacturing Platform, we were able to go from an initial concept to showing the final part on a show car in only three weeks, passing through many different design iterations to get the best result. Just three months later, we were able to move into production,” said Maurizio Reggiani, chief technical officer at Automobili Lamborghini.

“We wanted to give our designers and engineers the ability to produce better parts, and we can do this by leveraging Carbon DLS technology. We were also able to simplify the supply chain and reduce the time-to-market for these parts,” said Stefan Gramse, chief procurement officer at Automobili Lamborghini. “Moving forward we are putting more effort and resources on using additive manufacturing technologies for production of parts for Lamborghini vehicles, and in working with Carbon, we have found a partner that shares our vision for creating best-in-class products that push the limits of what’s possible.”

Through this and other partnerships with global companies, Carbon is applying years of learnings from high-volume production in adjacent markets to manufacture durable, end-use parts for the automotive sector.

Related Content

-

Getting into Plastics Additive Manufacturing? Avoid these Six Common Errors

There are a lot of 3D printing technologies out there, and it’s not uncommon for processors new to additive manufacturing to get tripped up. Here are some typical snafus, along with advice on how to avoid them before you start making parts.

-

NPE 2024: Additive Manufacturing Assisting, Advancing Plastics Processing

Exhibitors and presenters at the plastics show emphasized 3D printing as a complement and aid to more traditional production processes.

-

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.