System to recycle waste into 3D-printed filament to use in space

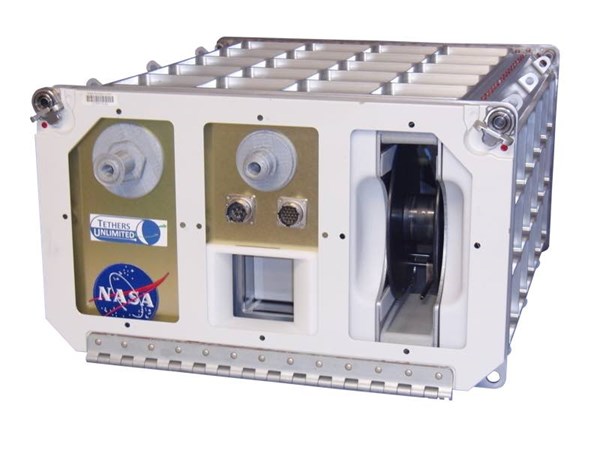

Tethers’ Positrusion recycler will turn plastic waste on the International Space Station (ISS) into high-quality 3D-printed filament.

So here’s a story that combines three very cool things: 3D printing, recycling plastic waste and space. NASA has announced that its Small Business Innovation Research (SBIR) Program has selected Tethers Unlimited Inc. (TUI, Bothell, WA, US) to develop a "Positrusion" recycling system for the International Space Station (ISS) and future deep-space manned missions. The Positrusion recycler will convert plastic waste into high-quality 3D printer filament for use in making tools, replacement parts and satellite components onboard the ISS.

TUI’s patent-pending Positrusion system uses what the company says is “novel techniques to process plastic into very high-quality filament for 3D printers.”

"Positrusion is a new approach to making 3D printer feedstock that produces filament with much more consistent diameter and density than traditional extrusion processes," said Jesse Cushing, TUI's principal investigator for the Positrusion effort. "That consistency will improve the quality of tools and other parts produced by 3D printers on the station."

It’s not just for space—TUI also sees significant potential for use of the Positrusion system in recycling plastic waste in the consumer market. "For a recycler to be useful on the ISS, it has to meet stringent safety requirements, and its design needs to minimize the amount of time an astronaut must spend operating it," said Jeffrey Slostad, TUI's chief engineer. "So we designed the Positrusion recycler to be as safe and simple to operate as a microwave oven, and we believe a consumer version of this machine will be ideal for recycling household and office waste."

Rob Hoyt, TUI's CEO and Chief Scientist, said that the company’s long-term goal is to create the capability to construct the habitats, spacecraft and other infrastructure necessary for exploration and settlement of the solar system using raw material launched from Earth as well as resources available in the space environment.

The company is developing an ecosystem of additive manufacturing technologies to make this possible, including 3D-printed “Versatile Structural Radiation Shielding” (VSRS), Structural Multi-Layer Insulation (S-MLI) and its Trusselator and SpiderFab technologies for fabricating key satellite components such as antennas and solar arrays.

“The Positrusion technology is an important part of this ecosystem, providing a way to process materials that would otherwise be thrown away into valuable feedstock for our in-space additive manufacturing systems,” he said.

First items ever manufactured in space with a 3D printer

This news comes on the heels of the recent reveal of the first items manufactured in space with a 3D printer. The items were unboxed on April 6 in the Additive Manufacturing Laboratory at NASA’s Marshall Space Flight Center in Huntsville, Alabama.

The items were manufactured as part of the 3D Printing in Zero-G Technology Demonstration on the space station to show that additive manufacturing can make a variety of parts and tools in space. In-space manufacturing technologies like 3D printing will help NASA explore Mars, asteroids and other locations.

To make the items, the printer heated a relatively low-temperature plastic filament to build parts, layer on top of layer, in designs supplied to the machine. The printer remains on aboard the station for continued use later this year.

The printer used 14 different designs and built a total of 21 items and some calibration coupons. The parts returned to Earth in February on the SpaceX Dragon. They were then delivered to Marshall where the testing to compare the ground controls to the flight parts will be conducted. Before the printer was launched to the space station, it made an identical set of parts. Now, materials engineers will put both the space samples and ground control samples literally under a microscope and through a series of tests. Project engineers will perform durability, strength and structural tests on both sets of printed items and even put them und an electron microscope to scan for differences in the objects.

To build and operate the printer, NASA worked with Made In Space Inc., a northern California company that is building the next-generation printer that will be operated on the station. This printer will be available to both commercial and government users.

Related Content

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreMake Every Shot Count: Mold Simulation Maximizes Functional Parts From Printed Tooling

If a printed tool only has a finite number of shots in it, why waste any of them on process development?

Read More3D Printing of Injection Molds Flows in a New Direction

Hybrids of additive manufacturing and CNC machining can shorten tooling turnaround times.

Read MoreThe Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More