Next-Generation Biodegradable Plastics Being Developed

France’s Carbios expands its patent portfolio on controlled lifetime biodegradation of plastics.

France’s Carbios expands its patent portfolio on controlled lifetime biodegradation of plastics.

The latest bad rap on biodegradable plastics comes from the UN’s top environmental scientist. Referring to such products as biodegradable water bottles and shopping bags, Jacqueline McGlade, chief scientist at the UN’s Environment Programme, warned that they are a false solution to the ubiquitous problem of litter in the oceans.

Addressing last month’s UN environmental assembly in Nairobi, attended by 170 countries, she said: “It’s well-intentioned but wrong. A lot of plastics labelled biodegradable, like shopping bags, will only break down in temperatures of 50 C (122 F), and that is not the ocean. They are also not buoyant, so they’re going to sink, so they’re not going to be exposed to UV and break down.”

She sees the main solution to plastics in the ocean as better waste collection and recycling, particularly in the developing world. She also noted that some of the biodegradable additives currently used in plastics have made such plastics harder to recycle and are potentially harmful in the natural environment.

Perhaps next-generation biodegradable plastics with an improved controlled lifespan can help make a difference as well. France’s Carbios, a 5-year-old ‘green chemistry’ company, specializing in breakthrough technologies dedicated to the recovery of plastic waste, is working on that and envisions the first industrial demonstrations to take place next year. The company was just granted two key U.S. patents and has exercised the worldwide licensing options on these patent families.

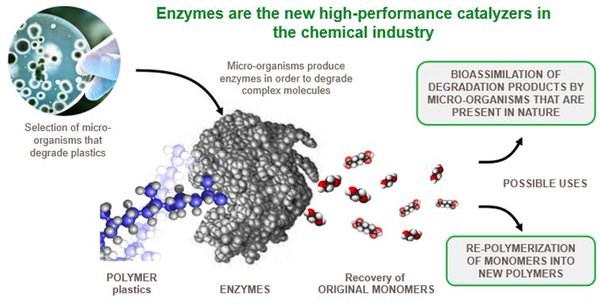

These licenses concern two patent families for Carbios. The first is for the proprietary process of enzyme infusion in plastics for which patents have been granted in France and in the U.S. The second covers a PLA degrading strain for which requests haves also been granted in France, the rest of the EU, U.S., Mexico, China and Japan.

Carbios acquired these exclusive licenses in 2012 from the CNRS--the University of Poitiers and VALAGRO Carbone Renouvelable as part of the THANAPLAST academic/industrial collaborative R&D project, for which it is the lead manager. They enable the company to grant sub-licenses on its biodegradation process. To date, the company biodegradation technology is founded on nine patent families: three on biodiversity and six on the production process of biodegradable plastics. (Another eight patents protect the company’s processes for recycling of plastic waste and the production of biopolymers.)

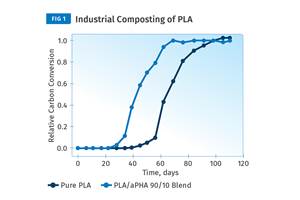

Carbios expects its PLA biodegradable technology to expand the breadth of application for PLA. Demonstrated on a pre-industrial scale, the company’s now patented enzyme-based technology, which entails embedding an enzyme in a thermoplastic at the time of production, reportedly renders it fully biodegradable at ambient temperature.

For nearly 10 months, the company has been operating a new pilot plant at its Saint-Beauzire headquarters, which enables it to reproduce biodegradable plastic films. The plant houses several production modules, from plastics extrusion to conversion to flexible films or solid parts, as well as the characterization of all properties of the materials produced.

Search for more on biodegradable plastics in PT’s Materials Database.

Related Content

Best Practices for Purging PHA and PHA/PLA Blends

Because bioplastics are processed at lower temperatures, purging between jobs requires a different process and purging agents than those applied for traditional resins.

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreAvantium and U.S.’s Origin Materials Aim to Accelerate Production of FDCA and PEF

The partnership aims to bring together both companies’ technology platforms to produce FDCA from sustainable wood residues on an industrial scale.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More