Not Thrilled by All the ‘4.0’ Talk?

Are you (perhaps secretly) put off by expressions like Industry 4.0, Internet of Things, Big Data, Smart Factories, Digitalization and so forth? If so, you’re not alone. You might be friendlier to terms like operational Transparency and Visibility.

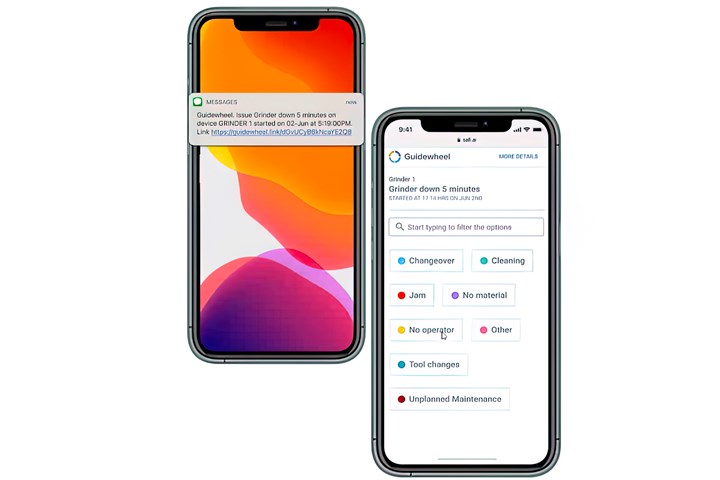

Don’t fret about whether you’re ready for Industry 4.0, IIOT, Digitalization, Big Data, etc. Job One is Transparency and Visibility of your operations. Nowadays, it’s all on your phone—how scary is that? (Photo: Guidewheel)

At the first-ever PTXPO show in March at the Rosemont, Ill., convention center, I had a few conversations about the omnipresent themes of automation, digital integration and advanced process control. A common element of those discussions was that American plastics processors don’t always speak the same language as their European counterparts. Europeans took the lead in popularizing terms and concepts related to “sustainability” and “circular economy,” and U.S. processors are quickly catching up. Europeans also were first to promulgate such language as, Industry 4.0, Industrial Internet of Things (IIOT), Digitalization, Smart Factories, Big Data and the like. Americans have accepted these with somewhat less enthusiasm.

In fact, several people I spoke to agreed with my suspicion that such terms actually turn some people off—more of them than might readily admit it. One vendor of integration software products told me it avoids using those terms when promoting its products in this country. I even wonder to myself sometimes whether attaching the “4.0” label to a story makes it more or less likely to be read. The consensus seemed to be that American processors are no less motivated than Europeans to maximize their manufacturing productivity, quality and profitability—they just have little patience with fancy new names for those long-established goals.

There’s nothing new about those goals, but we are fortunate enough to have new tools for achieving them. One set of those tools—a subset of all of what falls under the “4.0” umbrella—involves real-time production monitoring. In its simplest form, such a system records both numbers and durations of cyclic events, such as a clamp opening and closing, as well as machine uptime and downtime. With a little human input, additional data can be provided on downtime causes and scrap or reject rates and causes.

Systems to provide such info have been around for decades. I wrote about them frequently in the 1980s and ’90s, back when they required desk-sized consoles with bulky CRT screens. Nowadays, the same data is available on any PC, tablet or smartphone and can be supplemented by automatic email and text alerts that were hardly imaginable 30 years ago.

One thing that hasn’t changed much is that manufacturers too often find these systems to be costly and time-consuming to implement, including training personnel to use them. And if, like many processors, you have multiple plants in different geographies that came from corporate mergers and acquisitions, then you may be plagued with different, incompatible systems that measure different things in different ways, or the same things by different names. Sounds ugly enough to me.

For next month’s (June) issue, I interviewed a molding firm with more than two-dozen plants in five countries, 10 of them just recently acquired with one merger. That firm needed to do something about the hodgepodge of machine-monitoring systems and implement a common system economically and, above all, quickly. They found their answer in a remarkably simple and economical system that measures current draw (amperage) of any machine by clipping a small off-the-shelf sensor around the power cord. That measures the “heartbeat” of the machine—cycle times and counts, uptime/downtime, and whether the machine is running fast or slow or is possibly overloaded or in need of maintenance. What makes that data useful is uploading it to the internet (“cloud”), where it is analyzed and presented on a customized dashboard, customized for individual users by job function. The system can be installed on your own with just a video call for assistance, and it can be up and running within a day. You can access the data—and automated alerts—on your phone, tablet or PC. (I won’t keep you waiting for the June issue: the system vendor is Guidewheel.)

Whether or not they wince at terms like “Industry 4.0,” plastics processors have been adopting production-monitoring systems at a healthy pace. Almost all the processors I interview for reports like the one coming in June use such systems—for example, IQMS (now Delmiaworks) comes up frequently. These processors know the value of knowing which machines are operating or stopped, which are running slower than standard, which changeovers are more efficient than others, and OEE (overall equipment effectiveness) comparisons between machines, shifts or plants. Not letting a machine be idle for hours before the proper people are aware of it; not producing too much or too little for a job (after subtracting rejects) and not missing a ship date as a result--“That’s worth four or five percentage points of OEE and tens of thousands of dollars a month to us,” one automotive molder told me not so long ago.

Processors today can wave off scary terms like “Big Data,” because the data storage and number crunching occurs off in the “cloud,” refined continuously by artificial intelligence and machine learning, so all the user sees is a compact dashboard of just the data that user is interested in. Any data field can be expanded to drill down to exactly what went on at a particular machine at a particular time.

So let’s talk in more relatable terms about what all this really means to the user: manufacturing “transparency” and “visibility.” Like Superman’s X-Ray Vision, users can see exactly what’s going on throughout their own manufacturing universe. That’s a superpower every processor would want to have, and can have with today’s technology.

Related Content

Open Automation Enables Flexibility in Chemical Recycling

Software-defined equipment control systems can be duplicated, transferred and scaled with ease.

Read MoreFour Industry 4.0 Tech Adoption Insights from Indiana Plastics Manufacturers

As more plastics manufacturers step into the Fourth Industrial Revolution, insights have emerged about how best to approach the digital transformation journey.

Read MoreEngel Teases Generative AI Assistant at Digital Days Event

The Austrian maker of injection molding machines and automation introduced a prototype large-language model assistant for its customers: Engel GPT.

Read MoreEnsuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreRead Next

Paperless ‘Smart Factory’ Based on Automated Production Monitoring

Tier 1 automotive molder’s home-built production-monitoring and ERP systems, designed for “the little guy,” boost its efficiency rating and profits.

Read MoreMachine Monitoring Becomes Simpler And More Affordable Than Ever

A new application of an established technology makes production monitoring accessible to any manufacturer, with any type of equipment, and in almost no setup time.

Read MoreMachine Monitoring System Now Offers ‘Escalating Alerts’ of Downtime & Alarms

Guidewheel’s FactoryOps machine monitoring platform has a new feature to ensure faster response to downtime or other alerts.

Read More