Optimizing the Effective Life of Screws and Barrels

By adopting a few relatively simple practices, plastics processors can extend the life of the vital components of their plasticating unit. Here’s how to get started.

In today's competitive global marketplace, plastic processors can gain an advantage by incorporating a few relatively simple practices into their operations. In injection molding, extrusion or blow molding, the plasticating unit is the key to production efficiency and to the quality of the end product. The principal components of the plasticating unit, the feedscrew and barrel, should be designed to deliver maximum melting efficiency at the original clearances between the inside diameter of the barrel wall and the outside diameter of the screw flight. These clearances are usually minimal (0.001 in./side, per in. diam.), to achieve good heat transfer and shear rate.

As soon as the screw begins rotation inside the barrel, wear begins. The wear can occur either on the screw flights or the barrel surface, or both. The harder the material being processed, whether it is an abrasive filler in the polymer being processed or “tramp” metal particles that don't belong in the melt stream, the faster wear will occur and the original clearances will increase. As the clearances increase, melting efficiency will decrease. As melting efficiency decreases at the original settings, many operators tend to compensate by increasing screw speed, adjusting barrel temperatures, increasing backpressure, or some combination of those adjustments.

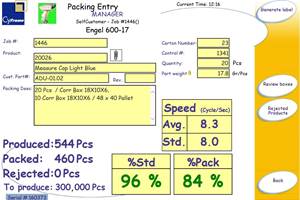

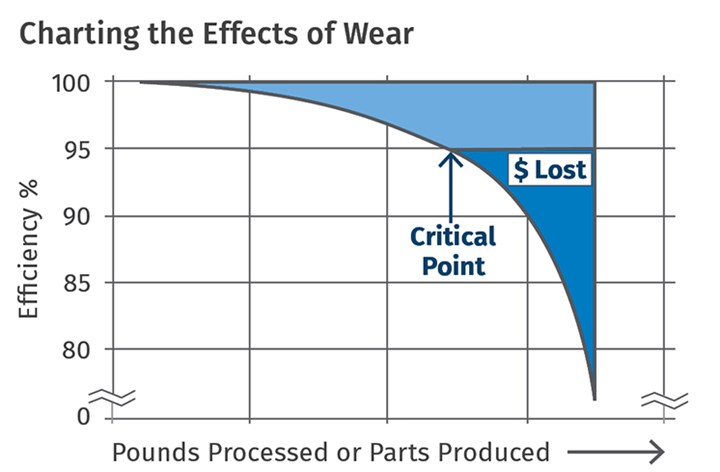

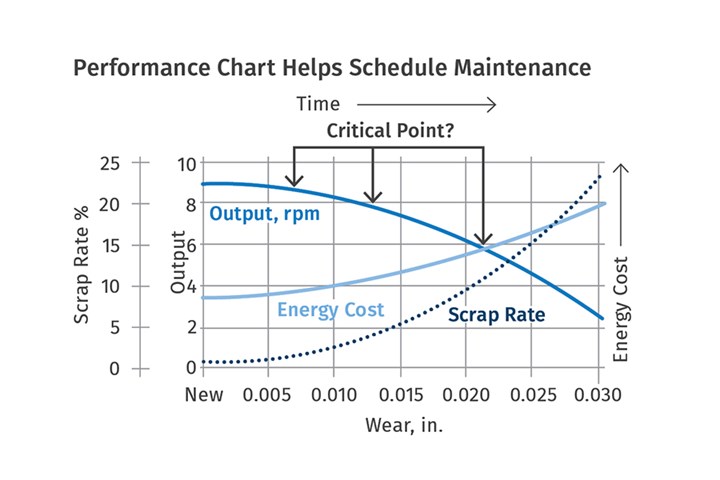

The adjustments are the operator's attempt to avoid longer cycles, unmelted material, higher melt temperatures, or higher scrap rates. Usually these changes are incremental and go unnoticed until they dramatically impact part quality or productivity (see Fig 1).

FIG 1 As soon as screw rotation begins inside the barrel, wear begins on the screw flights or the barrel surface, or both. As melting efficiency decreases at the original settings, many operators tend to make adjustments to avoid longer cycles, unmelted material, higher melt temperatures, or higher scrap rates. Usually these changes are incremental and go unnoticed until they dramatically impact part quality or productivity.

When the plasticating rate, production rate (whether measured in lb/hr or parts), or scrap rate reach unacceptable levels, a process engineer may begin to look for the cause. Unfortunately, at this point there is probably not a quick fix unless there is a spare screw or barrel around. If replacement parts are available, a changeout could be accomplished in a day or so. If not, the line would have to be shut down or run at reduced efficiency until replacement parts could be located and installed.

Types and Causes of Wear

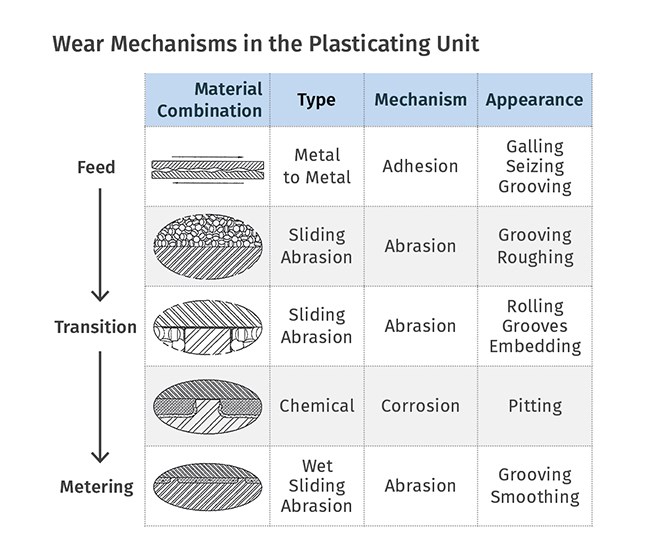

So how do you avoid this predicament? Let’s start by identifying the three types of wear.

1. Adhesive Wear. This occurs when metal surfaces (screw flight land and interior surface of the barrel) come in contact. Extremely high stresses occur when the surfaces briefly come in contact and weld together, then fracture. Evidence of adhesive wear can be a burr or "rolling over" of the trailing edge of the flight land or where hardfacing material is either scored or missing from the tops of the flights. The barrel should also be checked for scoring or galling of the I.D. at the point where the damage on the screw was located in the barrel.

2. Abrasive Wear. This may be the most common type of wear in plastics machinery. It can be minimal in cases where unfilled or low-viscosity polymers are being processed. As pellets are transported down the screw and compressed against the barrel wall, the shearing action will cause some degree of wear on the screw flight and the barrel wall. Abrasive wear can become significant when processing resins with fillers, additives or contaminants in the regrind, or even when processing high-viscosity polymers. Hard materials tend to remove material from softer surfaces. For this reason, the flight lands are usually hardfaced with alloys that are abrasion resistant. Glass- and mineral-filled resins can also cause wear to the root of the screw, usually in the rear of the channel, prior to the additive wetting and mixing with melted plastic.

3. Corrosive Wear. Corrosion is the gradual destruction of materials by chemical attack. Most of the atoms on the same metal surface are oxidized, damaging the entire surface. The breakdown of the metal surface actually allows the surfaces to be vulnerable to the mechanism of mechanical wear. Corrosion is most commonly experienced when processing PVC or polymers in the fluoropolymer family and will aggressively attack components that have a high iron matrix.

See the table below for wear mechanisms in the plasticating unit, and let’s take a deeper dive into some of the primary causes of wear.

• Straightness, Concentricity and Alignment: When preparing to install a new or rebuilt screw, the screw should be carefully checked for straightness and concentricity. If the old screw is available, it’s a good idea to compare the two for overall length, shank and drive configuration. Next, if the screw is to be installed in a new barrel (or the existing barrel is available and clean), slide the screw into the barrel and rotate by hand, if possible, to assure straightness and concentricity. The screw should rotate freely inside the barrel without interference or hangup. On extruders and most blow molding machines, prior to running the new parts, the machine should be aligned. Glycon Corp. has been aligning plastics processing machines for over 20 yr and in that time we have seen very few machines that did not require an alignment when checked.

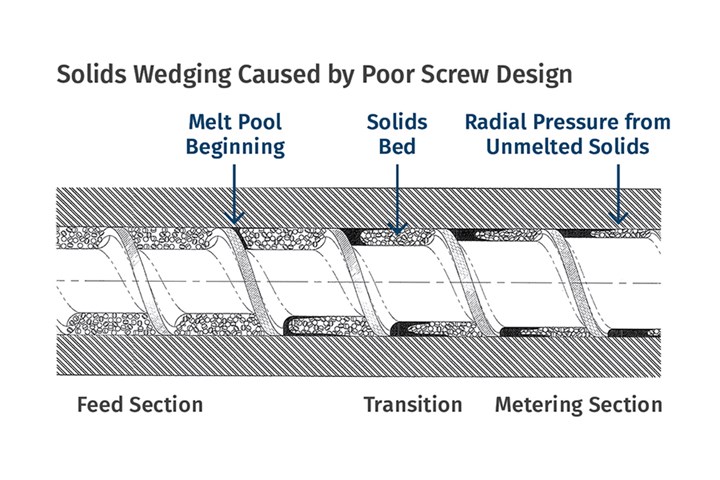

• Poor Screw Design: When the capacity of the melting section of a screw is less than the amount of unmelted material being delivered by the feed section, it can cause the channel to plug with unmelted material. The pressure generated actually forces the screw against the barrel on the opposite side, causing galling and damage to the screw flight as well as the barrel I.D. surface. This condition is often referred to as solids wedging (see Fig. 2). Solids wedging often occurs when a screw that was originally designed for processing a specific resin is run on a different polymer, with a different melting rate.

FIG 2 When the capacity of the melting section of a screw is less than the amount of unmelted material being delivered by the feed section, it can cause the channel to plug with unmelted material. The pressure generated actually forces the screw against the barrel on the opposite side, causing galling and damage to the screw flight as well as the barrel I.D. surface. This condition is often referred to as solids wedging.

• Incompatible Metals: Generally, softer materials have a greater tendency to gall when contacting harder materials. As a result, it is very important to consider the screw material as well as the screw flight hardfacing material and their compatibility with the barrel lining material. Alloys with lower tungsten carbide content may be easier to apply and finish, but, not surprisingly, offer less resistance to wear. They also have a greater tendency to gall, especially when run with some of the hardest barrel-lining materials. Today's bimetal barrels are available with excellent wear resistance. By utilizing centrifugally cast alloys with high tungsten carbide content, barrel manufacturers are capable of supplying a product that will provide long life. Then it becomes important to specify a screw that not only has a high hardness but runs compatibly with the barrel lining material.

• Abrasive Fillers, Additives, and Foreign Material: As applications for polymers and plastics become more specialized and more demanding, abrasive fillers and additives have necessitated improved protection from wear and corrosion. Resins with glass fibers, minerals, flame retardants, stabilizers and other additives require consideration of their impact on abrasive and sometimes corrosive wear in extrusion or molding with these materials. Some of the most aggressive fillers can reduce screw/barrel useful life by 50% or more. If screws and barrels are manufactured with proper protection, wear life can be extended and abrasive wear reduced considerably.

Another common cause of wear and damage to screws and barrels is foreign materials—everything from screwdrivers to grinder blades to nuts and bolts seem to find their way into hoppers on plastics machinery. If not caught by screens or magnets, these materials can cause significant damage to the screw and barrel. Hardfacing alloys breaking loose or delaminating from flight lands where the alloy has not bonded properly, or has developed cracks and broken loose, can also cause problems as they move down the screw.

Compensating and Diminishing Returns

As wear or damage to the screw and barrel occur, and the process engineer typically makes small adjustments to the screw speed, barrel temperatures or backpressure. These increments often use more energy and affect part quality. The effect may be minimal initially, but at some point these minor “tweaks” will have a measurable impact on production. It could be increased cycle time, poor mixing or higher scrap rates. This point can be referred to as the “point of diminishing benefit” or “diminishing returns.”

Ideally, we want to identify this point—the limit of where machine adjustments succeed in minimizing any reduction in productivity or quality—and be able to predict the timing of screw/barrel rebuilding or replacement. Whether this point is defined in terms of machine hours, parts produced or scrap rate, maintenance personnel can plan to change the screw/barrel and run to this point in the future. This will optimize the process, and at the same time, reduce the cost. Additionally, if we can identify this point, we can have replacement parts available and schedule installation at a time that does not interrupt production.

In the future, with digitalization, we hope to be able to measure screw and barrel wear accurately with sensors, then predict when parts should be re-built or replaced to maintain optimum productivity. Until that technology is perfected, plastics processors can chart performance related to screw and barrel wear by relating production efficiency to screw and barrel measurements (Fig 3).

FIG 3 When the capacity of the melting section of a screw is less than the amount of unmelted material being delivered by the feed section, it can cause the channel to plug with unmelted material. The pressure generated actually forces the screw against the barrel on the opposite side, causing galling and damage to the screw flight as well as the barrel I.D. surface. This condition is often referred to as solids wedging.

Unfortunately, especially on larger machines, measuring the screw and barrel at regular intervals may not be practical. However, if the adjustments to operating parameters are recorded and charted against changes in productivity, reference points can be established where the wear on the screw and barrel is indicated by the relationship to output, controller setpoints, energy consumption and the quality of the end product.

Everything from screwdrivers to grinder blades to nuts and bolts seem to find their way into hoppers on plastics machinery. If not caught by screens or magnets, these materials can cause significant damage to the screw and barrel.

Everything from screwdrivers to grinder blades to nuts and bolts seem to find their way into hoppers on plastics machinery. If not caught by screens or magnets, these materials can cause significant damage to the screw and barrel.With good record keeping, shutdowns for screw and barrel changes can be predicted with relative accuracy. The life of the components can be optimized, and "running to failure" as well as unplanned downtime can be avoided.

When installing a screw or barrel:

• The screw should be designed for the application.

• The screw and barrel should be manufactured from compatible alloys.

• The screw and barrel should be manufactured from the best wear-resistant materials for the application.

• Before installing, the screw and barrel should be carefully checked for dimensional accuracy.

• If possible, the screw and barrel should be checked for alignment.

ABOUT THE AUTHOR: Jeff Kuhman started in the plastics industry in 1969 when he joined Hartig. Later he worked for Barr Polymer Systems, then Uniloy, before starting Great Lakes Feedscrews (which later became Glycon) in 1978. Kuhman has been the CEO for 42 years. He the holder of six patents, including the widely popular QSO non-return valve for injection molding. Kuhman has been a member of SPE since 1970 and was a founding member of the SPE Blow Molding Division. Contact: 800-255-9969; jeffkuhman@glycon.com; glycon.com.

Related Content

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MorePart 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MoreUse Interactive Production Scheduling to Improve Your Plant's Efficiencies

When evaluating ERP solutions, consider the power of interactive production scheduling to effectively plan and allocate primary and secondary equipment, materials and resources on the overall production capacity of the business and conclude that this is a key area that cannot be overlooked.

Read MoreRead Next

How to Spec’ Screws & Barrels For Running Corrosive Materials

Here’s a guide to specifying screws and barrels that will last under conditions that will chew up standard equipment.

Read MoreFollow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

Read MoreShopping for a Barrel? Consider the Full Cost of Ownership

Beyond just the “invoice price” of a barrel, processors should consider factors like the composition of the inlay, quality of the backing material, straightness, concentricity, machining imperfections and packaging/handling, to understand the true cost of owning a barrel.

Read More