Polymer Tech Innovations To Star At 'NPE2015 Startup Garage'

Expect to see at least twelve startup ventures with exciting new technologies at the 'NPE2015 Startup Garage' exhibitions.

SPI is expanding its NPE2015 Startup Garage, the program it developed in partnership with the new-venture tracking firm Startup.Directory to provide startups with prominently located exhibit stations at the upcoming show this March.

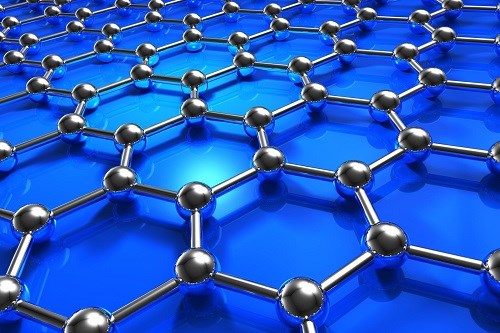

There are already twelve such startups exhibiting with innovations in bioplastics, recycling, 3D printing, polymerization, resin processing, and antimicrobial polymers. Three of these have developments in the burgeoning field of graphenes—two-dimensional carbon-atom nanostructures that can be used to formulate plastics composites with dramatically enhanced properties.

Originally the plan called for the selection of a limited number of startups by the partners, but with these twelve already on board and additional demand from the marketplace, SPI will expand Startup Garage space and accept more applications. Brad Williams, SPI’s director of trade show sales & marketing, noted that there has been an enthusiastic response by new companies doing exciting things at the forefront of polymer technology. “While some of these startups propose new ways to address pressing issues involving renewable resources and waste reduction, others offer enhancements of plastics manufacture and product performance. The quality of the exhibitors so far has led us to extend the call for more.” Here are the current twelve startups and their technologies:

• Aguas Pristinas S.A. Patented zero-waste beverage container and packaging system, with products designed to be recovered for re-use in other forms. One example, is roofing products derived from bottles. (web address not yet available).

• Biobent Polymers. “Bio-composite” polymers with up to 40% renewable content from soy or other renewable agricultural products.

• cycleWood Solutions Inc. Compostable and sustainable resins produced from lignin in tree byproducts generated during papermakeing, LDPE-like film grades are 100% compostable. Injection molding grades are available in either compostable or sustainable (blended with polyolefins) versions.

• Formlabs, Inc. 3D printing systems for engineers, designers, and artists. One system uses SLA (stereolithography) to produce high-resolution prototypes. The company also develops materials for 3D printing and 3D-printing software.

• Garmor Inc. Graphene priced for high-volume plastics applications. The company also has developed methods for incorporating graphene into plastics and shares this information with customers.

• iQLPE LLC. Development of polymer materials and manufacturing processes for polymer suppliers, converters, and end users. Solutions highlighted at the show will include semiconductor packaging, film and laminate extrusion, and structural polymers.

• Plastics EQ Corp. Web marketplace where companies post offers of and requests for recycled plastics online. The company integrates the full-sales cycle, including paperwork, payment/collection, freight management, credit check, etc.

• Productfast Automation. Technology for monitoring a manufacturing operation that replaces the Andon light system with wireless audio and visual effects.

• Smart E2 Solutions, LLC. System for producing fuel products from non-recyclable plastics. About a gallon of fuel is produced from 8 to 10 lb. of unwashed, unsorted waste plastic at a cost of less than $1.

• TiFiber Inc.Antimicrobial polymers that exhibit broad-spectrum activity against bacterial species, including drug-resistant strains such as MRSA. Among potential applications are medical devices and disposables, synthetic textiles, and consumer goods.

• Zzyzx Polymers.New “mechanochemical” process for compatibilizing, encapsulating, and fully dispersing materials into plastics, with a pilot plant established in Pennsylvania. To be highlighted at the show: graphene conductive PP; HIPS; and a polycarbonate-like PP.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More