Preview New Molding Simulation Release at Plastec West This Week

Molding simulation supplier Moldex3D previews the latest iteration of its software this week in Anaheim ahead of its full release in March.

If you’re visiting the Plastec West show in Anaheim, Calif., Feb. 6-8 (co-located with MD&M West and other concurrent exhibitions), you can preview the upcoming R16 version of Moldex3D molding simulation from Moldex3D Northern America, Farmington Hills, Mich. (booth 4033). The full release will arrive in early March.

Here are some highlights of the new release that you can see demonstrated at the show:

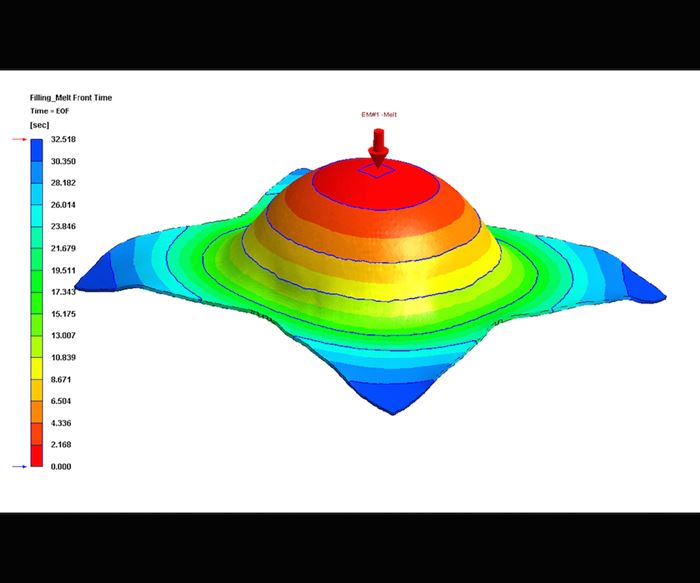

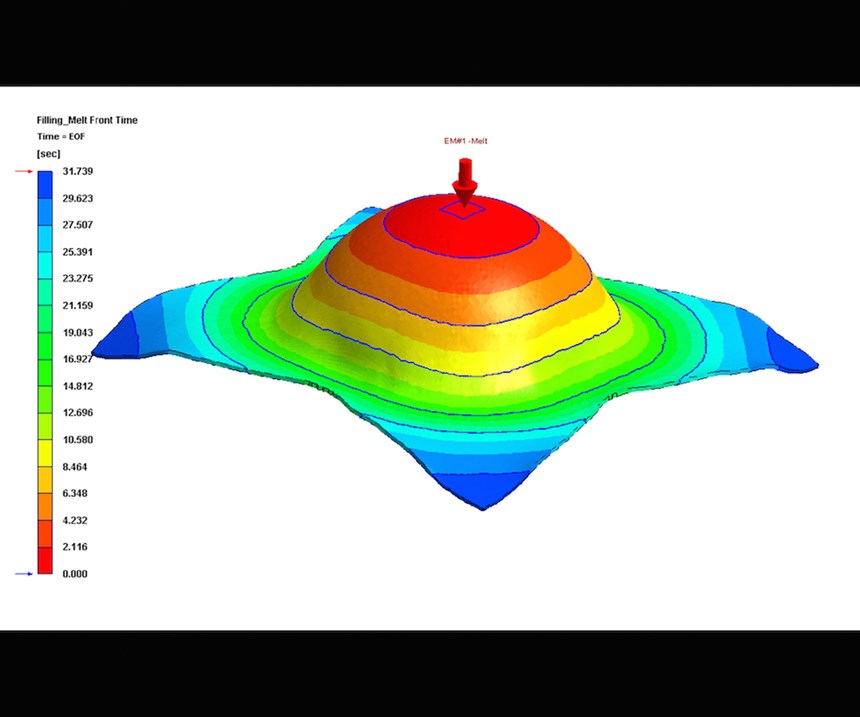

- Rapid mold gating iteration: Enables quick selection of optimized gate locations, especially for large parts, before committing to a comprehensive design validation analysis. Helps eliminate weld lines in early analysis stage.

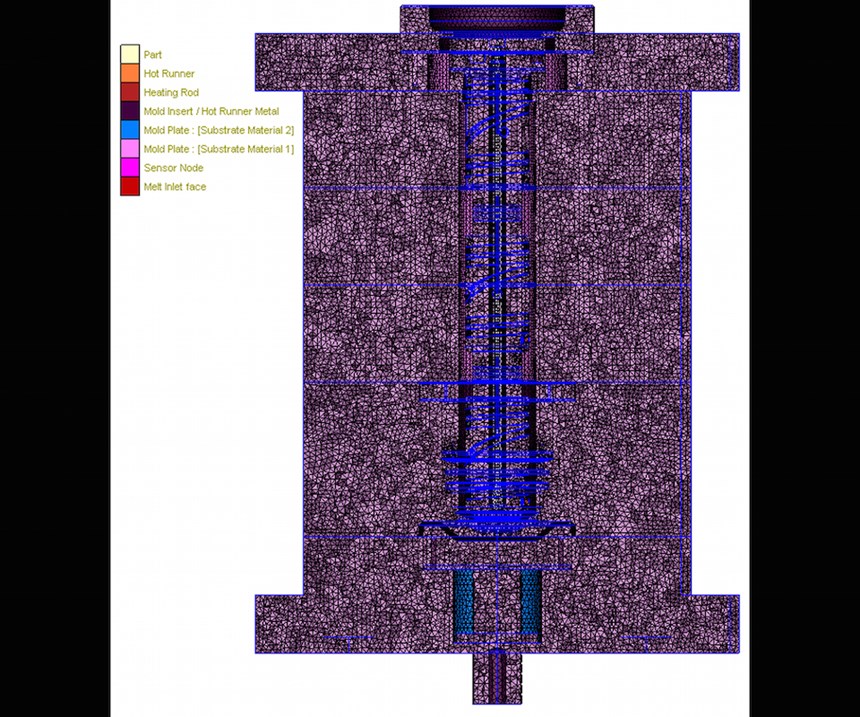

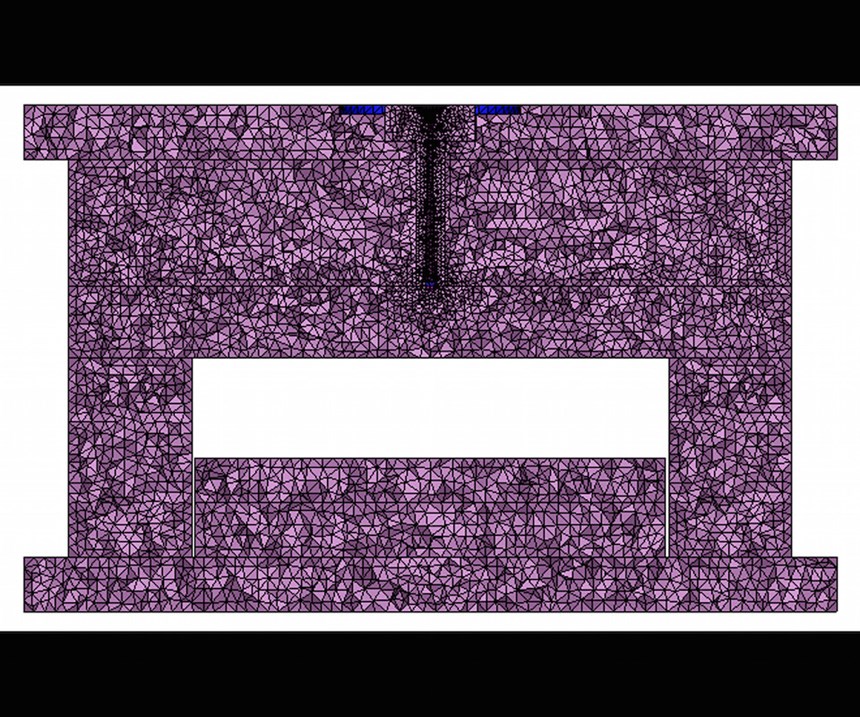

- Enhanced accuracy in simulating composites and special molding processes: Expands current simulation capabilities for resin transfer molding (RTM), polyurethane (PUR) chemical foaming, fiber-reinforced plastic injection molding, hot-runner molding, and more.

- Automated simulation workflow: Allows you to customize and automate simulation workflows through integrating Moldex3D with your product design systems.

- Faster simulation: Reduces filling/packing simulation processing time by up to 30%. Supports automatic generation of non-matched solid meshes for the entire moldbase and its components, including the mold plates, inserts, etc.

Learn more about Plastec West here.

Related Content

-

How to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.