Rethink Ramps Up Robotics Revolution With More Funding

GE Ventures and Goldman Sachs bet big on Baxter, the collaborative robot designed to reshape automation’s role in manufacturing and beyond.

When temperatures dipped into negative territory last week, some pipes in Rethink Robotics’ red-brick South Boston headquarters—a repurposed industrial space from the 1890s—burst, dousing desks but not dampening spirits for the innovative startup that is “rethinking” automation.

Rethink’s chief marketing officer, Jim Lawton, told Plastics Technology that his company’s plumbing issues had no impact on robots currently in production and did little to dismay the robot manufacturer in light of the news it announced on the same day: an additional $26.6 million in Series D financing coming from GE Ventures and Goldman Sachs.

Since its launch in 2008, Rethink has generated more than $100 million in funding, with this latest round to support continued innovation and global growth. To date, apart from robots installed at research institutions, the “several hundred” Baxter’s that are up and running in manufacturing are solely in the U.S., according to Lawton.

Not for long, however, as interest in the collaborative robots comes in from all over, particularly the Far East. “There’s a tremendous market for robots in Asia,” Lawton said. “China hasn’t leveraged automation nearly as much as other parts of the world.”

Learning From the Field

Following the 2008 founding, Rethink actually launched its Baxter line of collaborative robots in the fall of 2012, with its first orders shipped in the first quarter of 2013. Since those Baxter’s were deployed, Rethink has been rethinking its product, optimizing its collaborative robot.

“Now we have a couple of years of really good understanding,” Lawton said. “Here’s where [the robots] work, here’s where they don’t. What we’ve done since we started shipping the robot is build up a really good understanding of where you can deploy—here’s where it’s more challenging; here’s where it makes sense.”

Since those first Baxter’s were installed at the start of 2013, Lawton said Rethink has made changes, but primarily on the software side. On the hardware side, the company intentionally created a design that could “sustain us for a long time,” according to Lawton.

Imprecise Precision

Lawton noted that historically, automation has been about building out the most precise hardware and packaging it with a programmable software platform. Rethink purposely avoided building Baxter with the most exacting motors and gears in the world, and not just because they’re extraordinarily expensive.

Instead it designed Baxter with what is known as “compliant motion control” similar to how human arms work, allowing the robot to feel its way around a job.

All Baxter’s joints have springs in them, giving them certain amount of give. Where other robots utilize sensors and vision systems to try to achieve exact movements through space, adding cost and the potential for mishaps if elements become misaligned, Baxter operates via feel. Lawton says this allows the robot to work under imprecise pick and imprecise place scenarios, granting it greater flexibility for future jobs.

Lawton recalls visiting with a plastics customer in the Chicago area recently who pointed out his shop’s automation graveyard—a deserted corner of the plant where ultra precise systems that were too inflexible to take on new jobs had been mothballed ever since their molding run was up.

For Baxter, it’s a question of wheeling the robot to another job, and showing it what to do, according to Lawton. Improvements to Baxter’s programming algorithm have boosted speed and precision by “path planning” or figuring out the most efficient way for the robot to move through space.

Within plastics, the robots are tending machines, packing cartons, and undertaking general material handling tasks, including things like loading/unloading inserts. These are instances where a human could do the work, but it’s often tedious, making it prone to errors that generate scrap.

Putting a Face With a Robot

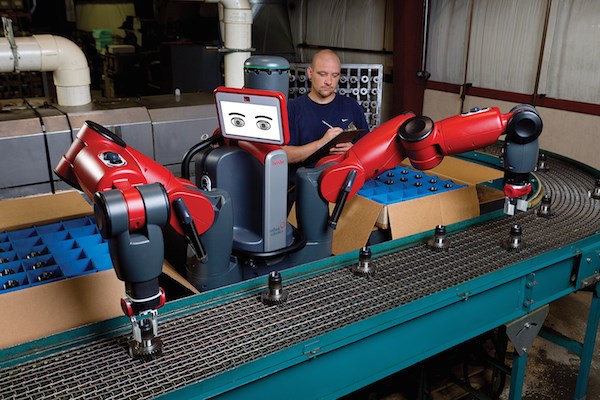

Where Baxter also differs is in how it interacts with the humans it’s designed to work alongside. The robot has a “face” that follows people that enter its work space and, as a human would, hints at its next move.

“If you were here and I took a drink, you would see my eyes glance at the drink before I would move,” Lawton explained. “You don’t think about that, but I’m sending you a signal, and you know what I’m going to do; you’re not surprised. Comfort comes from trusting that you have a general sense of where the robot is going to move.”

In addition to a face, Baxter is fixtured with human-like arms, giving people around it a clear understanding of its reach and range of movements, for instance. “I’m not dissing six-axis robots, they’re very good at what they do, but they really have to operate with a cage. They can be coiled like a snake—I have no idea how far it can reach, and how fast it can get there.”

If Baxter crowded you, however, you could get his attention, according to Lawton. “If I grab its arm it will look at me,” he explained. “Baxter has a face; he has anticipatory artificial intelligence; he will give an indication of what he’s likely to do before he does it. This helps humans get comfortable with a robot.”

Comfortable enough, that Lawton and Rethink believe collaborative robots can become a fixture in many settings, not just a molding cell.

“Last year, a lot of automation suppliers rebranded themselves as making collaborative robots,” Lawton said, adding that he thinks that’s a positive. “The concept has gone from intellectual curiosity to, ‘Wow these are real.’ I firmly believe you will see collaborative robots in every single manufacturing facility, every home.”

Related Content

Boston Dynamics Stretches Into Autonomous Warehouse Robotics

The robotics company’s second commercial product is designed to take on physically challenging warehouse tasks.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreDrones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More