Warehouses are the frontier for autonomous robots. As consumers become more accustomed to fast-turnaround shipping, warehouses need to operate faster and more efficiently. However, warehouses can be difficult working environments that require physically demanding labor such as moving heavy objects and repetitive motions. Naturally, interest is high in robotics and other automation solutions for warehouse work. “Automation doesn’t have limits around ergonomics,” notes Mike Murphy, a senior technical director at Boston Dynamics, a company probably best known for Spot, a robot dog that’s used for performing remote inspections. Murphy is also the chief systems engineer for Stretch, the company’s mobile case-handling robot that is specifically designed for warehouses.

However, warehouses can be challenging environments for robotics as well. On the surface, the work is straightforward and repetitive. “Take these boxes out of the truck, put them on this conveyor, move them, sort them, put them on these pallets, get them back out the door,” Murphy says. But, unlike in other applications where robots have traditionally found success, such as manufacturing, robots in warehouses are likely to encounter a wider range of variations and challenges. For example, boxes can open unexpectedly if they weren’t closed properly, or they can shift during transit and end up on the floor or other places they shouldn’t be. “Those are just the kinds of problems that we're starting to be able to solve with automation,” he explains. This knowledge can then be applied to new applications in other areas, such as manufacturing.

Boston Dynamics has released its second commercial product, an autonomous mobile robot (AMR) designed for warehouses. Stretch is a battery-powered robot the size of a pallet with onboard sensors that enable it to “see” its environment. Source: Boston Dynamics.

Meet Stretch

Stretch is a battery-powered mobile robot, equipped with an arm that has a powerful suction gripper. Stretch contains everything it needs to complete its job in a footprint roughly the size of a pallet. Its onboard cameras and sensors enable it to “see” the environment around it, recognize what’s happening, and react to and recover from any issues without preprogramming. An articulatable “perception mast” located on the turntable, next to the robotic arm, contains 2D and 3D sensors that gather data from all around the robot. Then, the operating system stitches the data together and runs it through a machine learning pipeline to detect boxes and determine where the faces and corners are located. “It understands where boxes are and what size they are, what orientation they’re in,” Murphy explains.

Stretch then performs “pick planning” based on what it has detected. The system takes into account environmental factors (such as walls, floors and ceilings) as well as the locations of all the boxes, the geometry of the gripper and robot arm, the robot arm’s reach and how all the boxes are interacting with one another. So, if Stretch is unloading a stack of boxes, it knows not to pick the box that’s on the bottom because that will knock the rest of the stack over, and it knows to wait to unload boxes near a wall or ceiling until other boxes are out of the way so it can get a better grip on them. Pick planning is crucial for Stretch. “If you make a bad decision there, you can end up creating an avalanche that takes a while for the robot to clean back up,” Murphy notes. Stretch can refine its pick planning strategy every pick or every few picks, depending on the mode it’s in.

Stretch is equipped with a vacuum gripper where each suction cup is individually controlled, enabling it to pick up boxes with holes, tears or dents. The suction cups that have good contact with the box get full suction power, while the ones that don’t are closed off, giving the entire gripper a better handle on the box.

The onboard sensors also detect anomalies in the environment, such as boxes that have fallen on the floor. “We have reactions in the behavior system to deal with those issues,” Murphy says. In many scenarios, Stretch will attempt to move the box anyway. “The boxes don’t need to be perfect for Stretch to function,” he says. Its vacuum gripper has what Boston Dynamics calls Smart Gripper technology, which controls each suction cup individually. This enables Stretch to pick up boxes with holes, tears or dents. “Whichever suction cups do have a good purchase against the surface of the box will get full suction and the other ones end up getting closed off so we don’t lose suction power,” Murphy explains. When Stretch encounters an issue it’s not designed to deal with, such as a box opening and spilling its contents on the ground, it can call for help from a “robot wrangler” who’s working nearby.

Working With Humans

The team has focused on truck unloading as the initial application for Stretch. When goods arrive at a warehouse, they must be moved from a truck, trailer or shipping container into the warehouse. During warmer months, these containers could be baking in the sun for hours, functioning like an oven, before an employee goes in to unload them. These jobs can be so difficult to fill that warehouses often turn to third-party companies to recruit and hire workers, and even then, turnover is high.

Boston Dynamics is focusing on truck unloading as the first application for Stretch. Not only is this a physically challenging task, especially when trucks have been sitting in the sun, it can be done mostly solo.

The difficulty of finding human workers for this task makes it an ideal application for Stretch, as is the fact that it can be done mostly solo. But Stretch still requires some help from humans — an operator must set Stretch up by driving it into the trailer or container and deal with any issues that require human intervention. “We have designed some systems to keep the robot operating safely,” Murphy says. One option is a portable cage that fully encloses Stretch into the trailer or container as it works. A human ensures no other humans are inside the cage before starting Stretch, and it will continue operating until the door opens or a human manually stops it. But, as Murphy notes, “our customers value flexibility, and they don't want cage panels in the way of all their other stuff.” So the company has developed a “virtual guarding” system. This uses sensors to set up a perimeter that slows Stretch down if it detects a person nearby, and stops it if a person gets too close. “We have a functional safety system onboard the robot that is able to ensure that the system comes to a safe stop,” he adds, “and there will be a manual restart if those conditions occur.”

For now, Stretch only moves autonomously in a safeguarded space, but eventually, it will be able to move fully autonomously through a warehouse among other people. Murphy says he doesn’t anticipate Stretch participating in shoulder-to-shoulder work with other humans. “Stretch is very strong and has a huge reach, and it really makes sense for it to work independently,” he explains. But as Stretch takes on more tasks in a warehouse, it will need to share space with people, especially when it needs help from a human. “We’re trying to be really thoughtful about the way that we can be quite confident that it's going to be doing that safely,” he says.

Onboarding

Because Stretch requires no preprogramming, the deployment process is relatively easy and fast. Murphy says it takes five days or less, and users are running the system on their own within a week. The process involves connecting network systems and electrical work, and physically or wirelessly connecting Stretch to the conveyor it places boxes onto to remove them from the trailer. Stretch can work with a variety of conveyors, from flexible accordion types that Stretch can drag with it to fixed, telescopic conveyors that can extend and retract on their own. Stretch can control the position of these conveyors and request the conveyor follow it into a trailer.

Workers receive two days of training during the commissioning process, learning how to drive Stretch around using a joystick on the pendant, how to intervene safely when Stretch needs a human’s help and what different error codes are and how to fix them. Once Stretch is in place, “it really looks like starting a laundry machine,” Murphy describes. “You follow the wizard, you push a few buttons, you hold down the start button and it unloads the truck.”

Stretch can be deployed in less than a week, according to the company. Once it is integrated with a conveyor belt, users can manually drive it onto the truck, push a few buttons and it can begin unloading boxes.

Success With Stretch

Stretch launched in early 2023, so it’s still fairly new, but customers are already seeing success. Murphy describes one user that had several third-party contractors who went on break and never came back, leaving a truck sitting in the sun full of heavy boxes that needed to be unloaded. Operators in the inbound area needed to find a way to unload the truck, so they decided to try using Stretch. “They put Stretch in and it unloaded the truck,” he says. “And they were just so happy that it solved their problem and didn't complain about the heat.”

Warehouses and Beyond

While Stretch has proven successful at unloading trucks, this is just one of many tasks in a warehouse. “We’ve designed the hardware system with the kinds of things that happen in warehouses in mind,” Murphy says, and the company is currently studying other possible applications from a business perspective to decide what to focus on next. “We have a lot of things we can have the robot do with basically software updates,” he says. One possibility is working with objects that aren’t boxes. “What else can Stretch unload from a truck? Whether it's tires or totes or, you know, anything that the gripper can grasp, it is certainly something that we would consider.”

The team is also looking at tasks that don’t involve unloading, such as moving objects from pallets to conveyors or vice versa and picking items from racks. “Anytime you would move an individual case from place to place, we want to understand what it takes to do that, from a technical perspective, but also in a business sense,” Murphy explains. “Does it make sense for this robot to be doing that job? And what are the typical challenges to do that?”

As for non-warehouse applications for Stretch, Boston Dynamics sees so much opportunity in the warehouse space that it hasn’t really looked outside of that environment for more applications. Murphy says manufacturing applications are a potential application, as is part sequencing for automotive applications. “But I think our minds are pretty focused on the warehouse space at the moment, because of the scale of it,” he adds.

From Research to Commercialization

Stretch is Boston Dynamics’ second commercialized product after Spot, the robot dog that’s designed for industrial inspection. Notably, Spot was developed while the company was focused on robotics research. “Our early customers and partners in that journey helped us find industrial inspection, for example, as an area where that kind of a platform could be really useful,” Murphy explains. In developing Stretch, the company wanted to understand the applications for its technology before launching the product. “The platform is capable of all these different applications in the warehouse,” he says. “But we already had a really good understanding of a couple we had a strong business case for and we understood the customer use case very well before we designed the platform. And then we’re expanding from there.”

According to Murphy, Stretch marks Boston Dynamics’ beginning as a serial producer of robotic products. “It really is making our transition to really transform our company to be focused on products, customer value, getting scale out in the world and being able to do all the things needed to have a successful suite of products from sales, to manufacturing and all the pillars you need to have a company that can do that at scale,” he says.

About the Author

Julia Hider is a senior editor for Modern Machine Shop, where she writes about the metalworking industry. She also serves as the robotics and autonomy correspondent for parent company Gardner Business Media.

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreFive Ways to Increase Productivity for Injection Molders

Faster setups, automation tools and proper training and support can go a long way.

Read MoreBMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

Read MoreRead Next

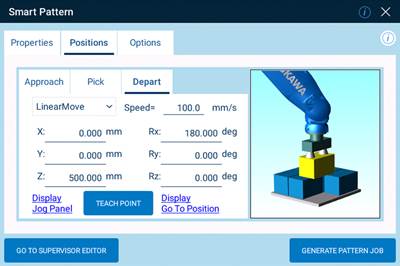

Software for Pattern Pick-and-Place Jobs with Six-Axis Robots

Free software download from Yaskawa Motoman helps define and select repetitive handling patterns.

Read MoreSecond Generation of Autonomous Machine Vision Systems Launched

Inspekto’s new S70 Gen. 2 offers reflection-free images and autonomous machine vision AI which reportedly take vision inspection to new heights.

Read MoreAutonomous Mobile Robot (AMR) Software Upgraded

AMR maker MiR says its newest software enables faster programming, tighter integration with other systems and enhanced cybersecurity.

Read More