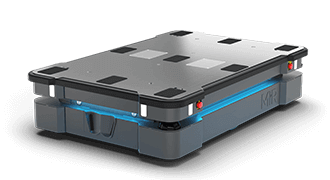

Autonomous Mobile Robot (AMR) Software Upgraded

AMR maker MiR says its newest software enables faster programming, tighter integration with other systems and enhanced cybersecurity.

Mobile Industrial Robots (MiR) introduced new software that it says will allow more robust and scalable autonomous mobile robots (AMRs) via faster programming, closer integration with other systems and enhanced cybersecurity.

The first phase of the new software focuses on a faster, more intuitive user interface for individual AMRs and entire fleets. In particular, MiR says the new software enables planning and re-planning navigation on the fly around obstacles with optimized reaction to anything moving nearby, including other robots, forklifts or human workers. It will also improve navigation in large facilities, with the ability to efficiently switch between different floors or production halls.

The new MiR software also features a completely redesigned user interface to enhance overall ease of use. The UI has different user levels and can be set up to run from desktop computers, smartphones and tablets, allowing employees to access different dashboards or summon robots with a single click.

In addition, MiR’s increased focus on cybersecurity prompted it to make several security improvements according to the IEC 62443 cybersecurity standard for industrial automation systems. These include software code signing; extended robot authentication; and an update of the robot operating system.

MiR has released updated software for its fleet of Autonomous Mobile Robots (AMR).

Photo Credit: MiR

Related Content

-

NPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.