SABIC Acquires Majority Stake in Carbon Nanotube Business for Energy Storage Applications

Company confirms it is also examining this proprietary technology in various materials and applications.

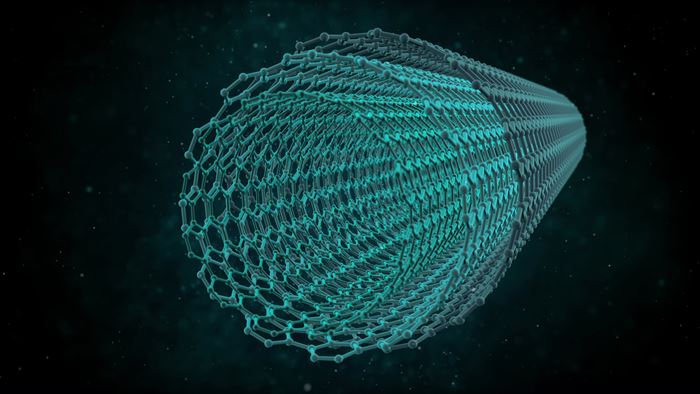

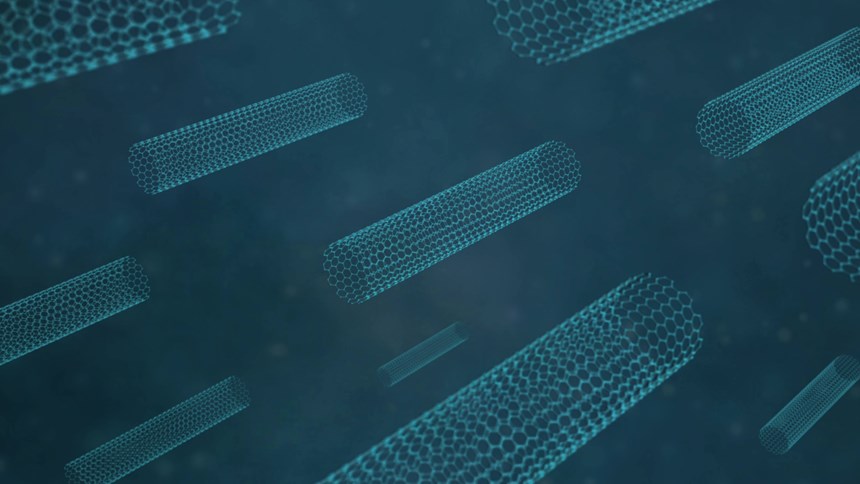

Just in case anyone thought that developments in carbon nanotubes may have stalled, all indications show advancements are ongoing. This is the case in both single-wall nanotubes from companies such as Luxemburg’s OCSiAL (U.S. office in Columbus, Ohio) as we have reported in the last two years and its more popular, generally lower-cost multi-wall ‘brethren’.

For example, we recently heard that SABIC, Houston, has acquired a majority stake in Black Diamond Structures (“BDS”), a nanotechnology company established in 2014. BDS of Austin, Texas, produces and commercializes Molecular Rebar, a proprietary technology of modified multi-wall carbon nanotubes that offers great potential for enhancing the performance of energy storage applications using lead-acid and lithium-ion batteries.

SABIC is adding BDS to its Specialties business, which includes a broad range of specialty materials—from its well-known engineering thermoplastic resins and compounds, to composites, functional surface substrates, ethylene oxide derivatives, and additive manufacturing filaments and reinforced compounds. According to v.p. of SABIC’s Specialties Alan Leung, the carbon nanotube technology of BDS will allow Specialties to address several demanding challenges in the energy storage market.

In particular, BDS provides benefits to battery manufacturers looking for improvements in charge rates, battery cycle life and energy density. Conventional carbon nanotubes are known for their tendency to get entangled, cake and hold high residual impurities, limiting their capabilities of enhancing electrical and mechanical material properties in real world applications. In contrast, the Molecular Rebar product supplied by BDS delivers clean and discrete carbon nanotubes of uniform aspect ratio, enabling their use to create high-performance energy storage applications.

Meanwhile, BDS’ CEO John Hacskaylo, says that this proprietary nanomaterial can be directly incorporated in existing production processes of batteries without requiring additional investments, allowing a fast-track for manufacturers to improve their next generation of batteries. Tests have shown that Molecular Rebar type carbon nanotubes significantly improve the cycle life of a lead-acid battery and enhance the performance of lithium-ion batteries to meet the increased power capacity demands of the industry.

Moreover, Hacskaylo expects Molecular Rebar to play an effective role in the downgauging and downsizing of new battery designs. This not only meets the growing global demand for lighter batteries in the hybrid and electric vehicles market, but also reduces battery production costs, helping manufacturers to increase output and achieve higher economies of scale.

SABIC’s initial thrust of development and application of Molecular Rebar will be used to enhance the performance of the active material of the battery itself. However, company sources confirm that the company is currently developing and testing the use of Molecular Rebar technology in various materials and applications, but opt not to share details at this stage. Leung, himself, envisions that adding the technology to the portfolio of SABIC’s Specialties business is likely to unleash innovations in material science for enhancing the properties of specialty resins and functional compounds.

Related Content

-

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.