Satellite With 3D-Printed Thermoplastic Chassis to Launch into Space

The project is also an experiment to test the viability of satellites with 3D-printed parts in the harsh environment of space.

The project is also an experiment test the viability of satellites with 3D-printed parts in the harsh environment of space.

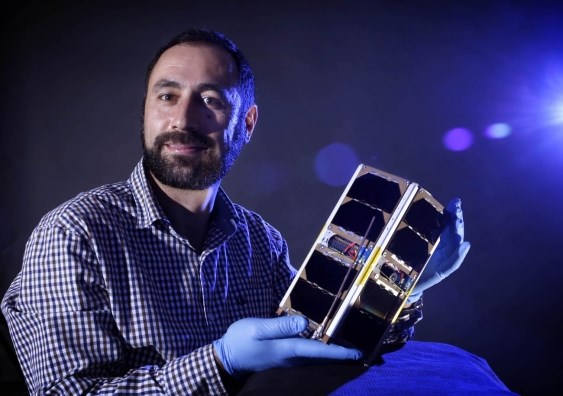

Three satellites created by the Australian Centre for Space Engineering Research (ACSER) will launch to the International Space Station this year where they will be deployed into orbit to explore a little understood region above Earth known as thermosphere. And here’s a component to note: one of the satellites, called UNSW-Ec0, features a chassis made entirely from 3D-printed thermoplastic.

“This region is poorly understood and hard to measure,” said Andrew Dempster, Director of Australian Centre for Space Engineering Research (ACSER) at University of New South Wales (UNSW). “And yet, it’s the interface between our planet and space. It’s where much of the ultraviolet and X-ray radiation from the Sun collides with the Earth, and generates auroras and potential hazards that can affect power grids and communications.”

The satellite is part of an international project known as QB50, which will see a total of 50 small satellites—known as cubesats and weighing just a kilo each—carry out the most extensive measurements ever undertaken of the region between 200 and 380 km above Earth. Each cubesat also carries other instruments with its own engineering and scientific goals. UNSW-Ec0, for example, has three other experiments: a robust computer chip designed to avoid crashing in the harsh radiation of space, as some satellites and space probes are forced to do when hit by cosmic rays; a space-borne GPS to allow satellites to cluster together in swarms; and test a super-reliable computer microkernel in the harsh radiation of space.

The UNSW-Ec0 satellite, along with the other QB50 satellites, will be launched together by an Orbital ATK Antares rocket on Dec. 30, 2016 from Wallops Island, Va.

“This is the most extensive exploration of the lower thermosphere ever, collecting measurements in the kind of detail never before tried,” said Elias Aboutanios, project leader of UNSW-Ec0 and a senior lecturer at UNSW. “The satellites will operate for 3-9 months – and may last up to a year – orbiting this little-studied region of space, before their orbits decay and they re-enter the atmosphere and burn up.”

We’ll keep an eye on this one to see if how the 3D-printed thermoplastic components fare in space.

Related Content

-

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

-

420 Stainless Steel Now Qualified With TrueShape 3D Printing Technology

NPE2024: Mantle's additive manufacturing technology is designed for precision tooling.

-

Production Tool, Prototype Time

Mantle's metal 3D printing technology targeted toolmaking and injection molders and moldmakers are taking notice.