Several 'Firsts' Characterize Winners of SPE Auto Innovation Awards

With the addition of an ‘additive manufacturing’ category, the winners of all nine categories exemplify continued innovation and transferability in the use of plastics.

The 48th annual Automotive Innovation Awards Competition was celebrated by SPE’s Automotive Division at its gala in Livonia, Mich., with the announcement of the winners of this year’s nine categories, including the newly-added ‘additive manufacturing’ slot. For this editor, it was once again an honor to be a participating judge in this well-recognized event.

SPE’s Automotive Innovation Awards Program is the oldest and largest competition of its kind globally. Dozens of teams made up of OEMs, tier suppliers, and polymer producers submit nominations describing their part, system, or complete vehicle and why it merits the claim as the Year’s Most Innovative Use of Plastics. This event typically draws over 700 OEM engineers, automotive and plastics industry executives, and media. Funds raised from this event are used to support SPE educational efforts and technical seminars, which help educate and secure the role of plastics in the advancement of the automobile.

Here’s a brief look at the nine winners, starting with the grand winner award—also the winner of the Powertrain category. In future blogs, I will highlight some of the other contenders in the various categories that definitely merit attention.

Powertrain/Grand Award Winner—Vacuum Generation System for Brake Assist

The open/close valve actuation is accomplished via two complementary resin systems acting in concert to provide for critical no “stick-slip” and no measurable wear after 2,500,000 hot/cold test cycles. Injection molding allows for very close tolerances of critical details necessary for total system performance. A 40% weight savings and a 25% cost savings over current pump systems were achieved.

OEM Make & Model: 2017 Ford Motor Co. Ford F-150 pickup

Tier Supplier/Processor: Dayco Products/MacLean-Fogg, Engineered Plastics Co.

Material Supplier/Toolmaker: DuPont Automotive/Kaid Tool & Die

Material/Process: Delrin 73M30 POM+PTFE, Minion 520MP PA6/injection molding

Additive Manufacturing—Window Alignment Fixture

This additive fixture was 30% lighter and cheaper to produce vs. a traditional welded fixture. It was also much faster to manufacture—only 50 hours to build the integrated fixture with handles and mounting brackets. Ergonomics were improved significantly. The plastic fixture allows for easier handling and avoided the requirement for a lift assist. The printed fixture integrated pneumatic control, eyelets for a stowage rack, trigger switch housing, ergonomic handles, gage protector deflector and pneumatic tubing retainers and switch mounts.

OEM Make & Model: 2017 Ford Motor Co. Mustang Convertible sports car

Tier Supplier/Processor: Stratasys/Stratasys

Material Supplier/Toolmaker: Stratasys/Stratasys Direct Manufacturing

Material/Process: PA 12 35% short carbon fiber/ Fused Deposition Modeling (FDM)

Body Exterior—Thermoplastic Liftgate

Replacing a steel liftgate with a new thermoplastic design enabled a 28% mass reduction and a 50% tooling and capital investment savings through part integration and manufacturing efficiency. An industry first use of conformal infrared welding behind the MIC grain class A surface increased structural and dimensional performance and enabled quicker processing. Bonded-in brackets enabled patent pending tethering attachments without fasteners, improved metal reinforcement efficiency and maintained styling surface wrap in D pillars without sacrificing DLO. All this was accomplished within an 18-month window.

OEM Make & Model: 2019 Fiat Chrysler Automobiles Jeep Cherokee SUV

Tier Supplier/Processor: Magna International Inc./Magna Exteriors Belvidere

Material Supplier/Toolmaker: Trinseo & LyondellBasell /Tycos Tool & Die

Material/Process: DLGF 9411 & Hifax TYC TPO/injection molding

Body Interior—Integrated Modular Pelvic Bolster

This application combines two unique side-impact bolster designs to meet the requirements for 5th and 50th percentile occupants. Integrating them into the map packet resulted in tooling cost savings estimated at $100,000. There was an additional $100,000 in direct savings in testing time and $8 per vehicle cost avoidance if add-on bolsters were used. An approximate 10% weight savings was achieved. Modular features were added to improve performance, by increasing flexibility of design, and reduce use of multiple bolster parts.

OEM Make & Model: 2018 Ford Motor Co. Lincoln Navigator SUV

Tier Supplier/Processor: Faurecia Interior Systems/Faurecia Interior Systems

Material Supplier/Toolmaker: LyondellBassell/Roush Tooling

Material/Process: Profax SG702 PP/injection molding

Chassis/Hardware—High Strength Self-tapping Composite Nut

This composite nut has self-healing properties enabling it to maintain sufficient torque and clamp load even after it has been stripped, unlike the metal nut that this composite nut replaces. Total mass savings is 8g per location x 121 locations for a total vehicle mass savings of 2.1 lb specific to the Chrysler Pacifica. The estimated cost savings per vehicle is $3.25. The composite nut can be translated across all OEMs and in many additional applications.

OEM Make & Model: 2016 Fiat Chrysler Automobiles Chrysler—Pacifica minivan

Tier Supplier/Processor: ITW Deltar Fasteners/ITW Deltar Fasteners

Material Supplier/Toolmaker: Asahi Kasei Plastics/Maple Mold

Material/Process: Leona 90G55 PA66/injection molding

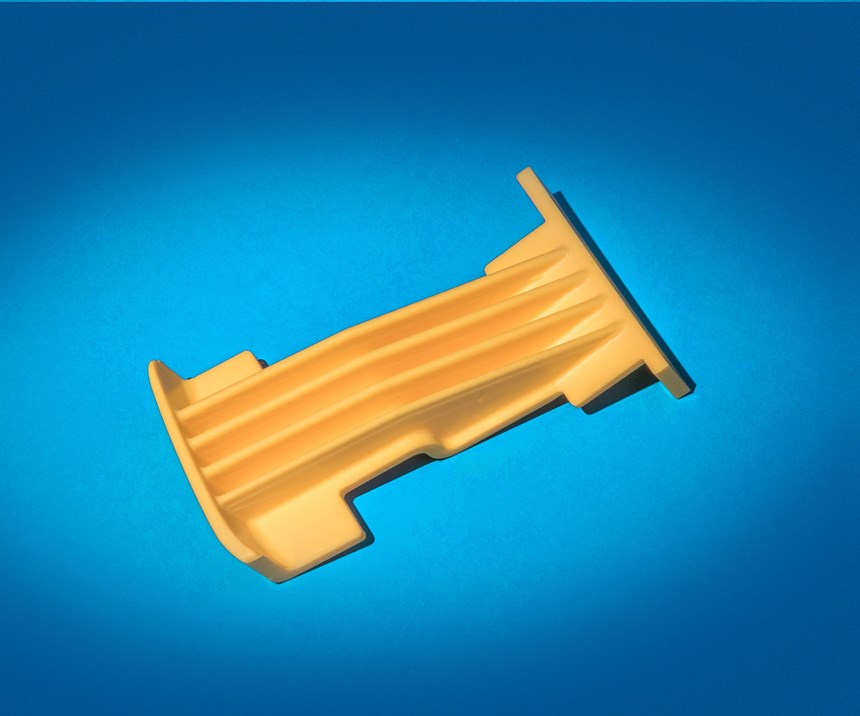

Environmental—Sustainable Hybrid Composites

This is an industry first application of composites combining tree (cellulose) fiber with long glass fiber (LGF) in a polypropylene (PP) matrix to replace 35% short glass-mineral filled PP. A 24% weight savings and a 13% cost savings were realized. A total $2 million cost savings resulted by reducing weight and reducing cycle times by 20% - 40%. A life cycle assessment improvement was also attained.

OEM Make & Model: 2018 Ford Motor Co. Lincoln Continental luxury sedan

Tier Supplier/Processor: Summit Polymers/Summit Polymers

Material Supplier/Toolmaker: Celanese & International Paper/Summit Polymers

Material/Process: THRIVE & Celstran PP+HC (CF/LGF) PP/RPP/melt compounding followed by injection molding

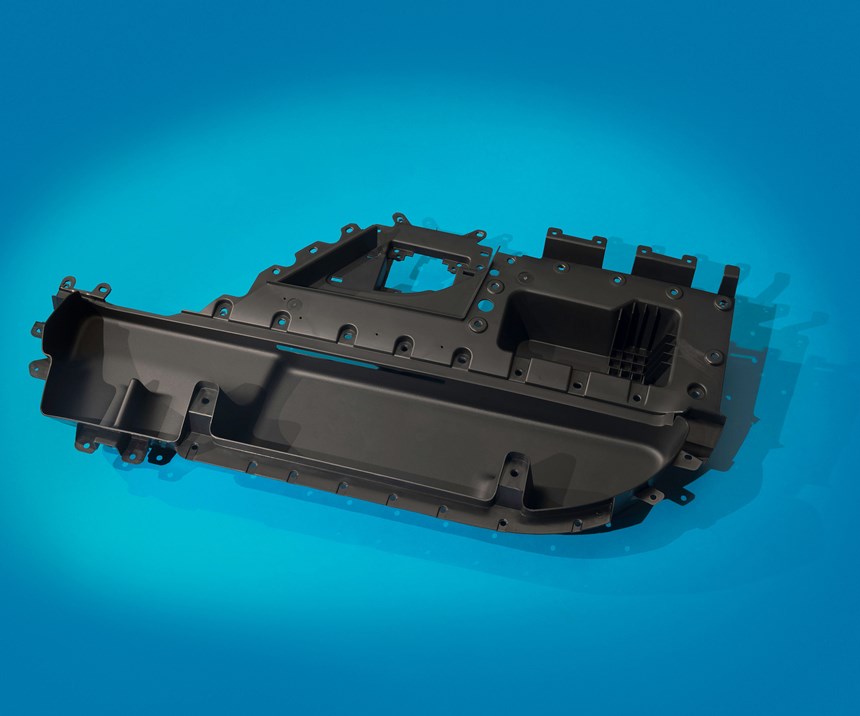

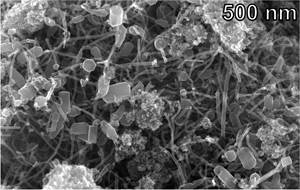

Materials—EMI Shielding Compounds for High-Voltage Cover

New conductive plastic compound materials for EMI (Electromagnetic Interference) shielding were developed for high-voltage junction box upper covers. The material replaces conventional die cast aluminum covers for reduced weight and manufacturing costs. The materials are Polyamide 6/PPO compounds with hybrid conductive carbon filler (Carbon fiber, nano carbon fiber filler—CNT, Carbon black) not containing metal powder or metal coated fiber. The weight savings is estimated at 30% (0.3kg) and the cost savings is estimated at 70% ($50 per vehicle.)

OEM Make & Model: 2019 Hyundai Motor Co. Hyundai Nexo SUV

Tier Supplier/Processor: Yura Corporation/Yura Corporation

Material Supplier/Toolmaker: Hanwha Compound/Hyundai Motor Co.

Material/Process: Hanwha Compound ESM-204B PA6/injection molding

Process/Assembly/Enabling Technologies—Integrated Tire Carrier, Rear Camera & Brake Light Assembly

This hybrid composite technology utilizes magnesium injection molding for higher structural strength with reduced weight & polymer over molding for improved impact and corrosion resistance. A 60% weight savings is achieved compared to metal stamping and a 20% weight savings is achieved compared to die casting processing methods. A cost savings of 20% is achieved with an improved load rating from 85 to 115 lb. The new design eliminates the need for a steel bracket for an indirect cost savings.

OEM Make & Model: 2018 Fiat Chrysler Automobiles Jeep Wrangler SUV

Tier Supplier/Processor: TMD-Grammer AG Group/Leggera Technologies

Material Supplier/Toolmaker: DuPont/Leggera Technologies

Material/Process: Zytel ST 801 AW PA66/injection molding

Safety—Interlocking Mechanism Design for Side Impact

This interlocking mechanism improves door trim performance during side impacts by preventing fracture or separation of components that could cause sharp edges. This patent-pending design provides strong attachment, force absorption and high impact resistance between two components during side impact. It replaces the need for metal bracket reinforcement solutions (saving 3.70kg in weight per vehicle). A cost avoidance savings of $30.60 per vehicle and a tooling investment of $9.88 million is achieved.

OEM Make & Model: 2019 Ford Motor Co. Ford Transit Connect van

Tier Supplier/Processor: Faurecia Interior Systems/Thermolympic SL

Material Supplier/Toolmaker: Trinseo/Meymol SL

Material/Process: Magnum 3325MT ABS/injection molding

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More