Shiny New Hot-Runner Plant Is High Tech Showplace

HRSflow employs automation, sophisticated software tools in its first North American production plant.

Palletized manifold production.

Over 200 guests at the official opening of HRSflow North America, the newest manufacturing location of the Italian hot-runner firm, were treated to a two-hour tour of the spanking new facility, whose 40,000 ft2 house CAD/CAE design capabilities, six CNC machining centers, a quality-control lab, and a 1000-ton injection press for mold trials (see Starting Up). John Blundy, president of the operation, says, “It’s the most modern, innovative plant in North America for producing hot runners.” Blundy is a 40-year veteran in the injection molding business, including 15 years at Incoe.

Robot unloading nozzles from lathe.

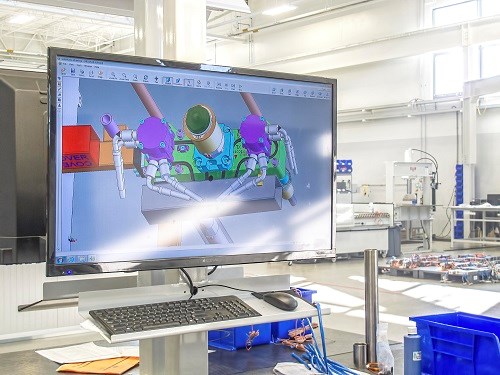

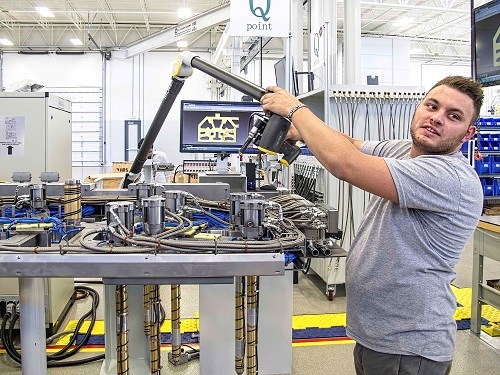

On the manufacturing floor are three CNC milling systems and three lathes, including a palletized system that can run load up to seven manifolds to run “lights out.” One lathe can run for two days unattended, thanks to an automatic bar-stock loader, auto tool changer, and six-axis robot that removes finished nozzles and places them in a storage rack. Finished components are stored in a Modula automatic storage/retrieval system. Upon entry of a job’s barcode, the system picks all the components for an assembly and packs them in a box. Assemblers work from 3D CAD models on a screen in this paperless plant. A new step in final assembly is a 3D scan of the assembled system with a handheld laser scanner; any interferences or variations from print are displayed in color on a screen. The final quality check is a warm-up to confirm that heaters and thermocouples are functioning properly, as well as cycling the valve cylinders and performing a vacuum test to check that the manifold is airtight.

Paperless production system.

The new plant’s metrology lab has a touch CMM system to perform 100% inspection of all system components, automated via barcode, something that’s not common in the industry, according to plant manager Andrea Zigante.

Laser scan of final assemblies.

Design capabilities at the new plant include CAD systems, Ansys engineering analysis, and mold simulation via Autodesk Moldflow and Moldex 3D software, including ability to analyze warpage, fiber orientation, coinjection, and injection-compression. HRSflow also performs thermal and pressure-drop analyses on all new system models. In addition, HRSflow created its own mathematical models to predict color-change phenomena. For example, simulation of interior door panels guided system design to permit a predicted change from black to gray in 9-10 shots and from gray to black in five shots.

1000-ton injection press for mold trials.

Other software tools include tooling standards that ensure that designers incorporate, for example, hydraulic components for a mold that are compatible with the type of injection press it will run on. And once a system is in the field, HRSflow technicians have access to new web-based troubleshooting software available 24/7/365.

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.