So How Fast Can You Change a Mold?

A contest next month at a U.K. trade show will crown one molder king of the quick-change artists.

A contest next month at a U.K. trade show will crown one molder king of the quick-change artists.

My colleague Tony Deligio has blogged a bit recently about benchmarking and our 2016 World Class Processors survey (click here to participate). And now, if you’re really good at one key metric you might even win a prize.

Molders from across the U.K. are set to compete for “best in class” honors in mold changing during the PDM Event, a plastics industry trade show scheduled for June 14-15 at the Telford International Center in the U.K.

Ever been to a NASCAR race and see a pit crew in action? Well, at the show contestants will have 60 minutes in The Quick Mold Change Competition to change a mold correctly, safely and as quickly as possible on an Engel press. RJG Technologies, who along with Engel U.K. is sponsoring the contest, will judge.

Molders are invited to enter a team of two technicians for the competition. Entrants will compete to be the fastest to complete the tool change under the judges’ scrutiny to ensure safe working methods. The final installation will be inspected to ensure correct installation including mold operation, set up of water pipes, clamp positioning and torque settings. Judges will also check that the tool is demounted correctly and the work area left tidy.

The team that wins the challenge will receive a trophy as well as two £200 (about $227) vouchers from Amazon.

“Fast tool change in production can increase both injection mold availability and safety levels during mold changeover,” says Richard Brown, RJG managing director. “The Quick Mold Change Competition at the PDM Event 2016 is a great opportunity for mold technicians to prove their skills against the clock to find the fastest and safest tool change team within the industry.”

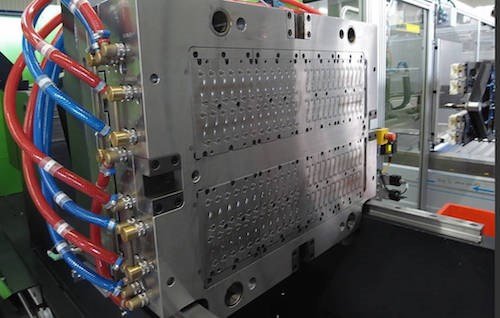

Adds Graeme Herlihy, managing director, Engel UK, “(We are) delighted to be supporting the PDM Quick Mold Competition by providing one of our machines for molders to use at the show. Our tie-bar-less design will certainly make it easier for competitors to carry out a mold change quickly, safely and accurately. It will also be an effective showcase for our flexible, cost effective and highly energy efficient machines.”

(Photo: Large mold running in a tiebarless Engel machine)

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

-

The Impact of Hydraulics on Tool Design -- Part 1 of 2

Get a better understanding of their use, proper sizing, and how the tool design and setup in the machine can impact failures in manufacturing.