The Five “Ms” of Molding—Part II: The Mold

A bad mold can cripple a process; learn what areas should be considered as a tool is evaluated and reviewed.

A bad mold can cripple a process; learn what areas should be considered as a tool is evaluated and reviewed.

Tooling is a key foundation block when developing a work program. A poorly designed or improperly functioning mold can become the root cause for systematic failures. In addition, as continuous improvement projects are outlined, the mold should be reviewed for potential improvements through modification. The next section outlines major areas that should be considered as the tool is evaluated and reviewed:

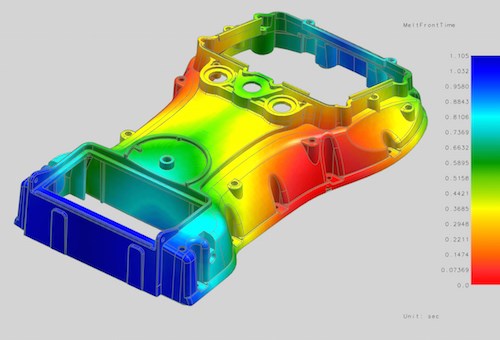

Design: The very first step of successful molding is how well the mold has been designed to fit a particular application. Molds that do not perform well because of poor processing capabilities, frequent breakage or fluctuating molding conditions are crippling to a company’s productivity and efficiencies. Molding simulation software is a great tool for mold development. The ability to analyze mold temperature, pressure fluctuation and how the flowfront will likely perform greatly improves the designer’s ability to make adjustments to the tooling to counteract potential molding problems before they happen.

Qualification-Tooling: There are many different aspects to mold qualification. The primary goal of qualifying a mold is to develop tooling that consistently produces quality parts at an optimal cycle time. Here is a list of some of the primary areas that are important to mold qualification.

Balancing the runner system: The need to verify that the cavitation is balanced is paramount to a molder’s ability to control his process. Part weights should be consistent and equal. Parts that weigh more or less than the mean should be adjusted by making changes to the gates. Sprue, runners and gates should allow for adequate filling based on material properties.

Mold Temperature: The ability to heat or cool the mold consistently is a vital part of building a consistent process. The mold faces should be checked in multiple areas to verify that temperatures are equal and consistent. Hot or cold spots can cause major inconsistencies. Adding or removing circuits might be needed to accomplish this. In addition, the mold circuitry should be clearly marked to prevent irregular set ups and assure turbulent flow and consistent direction. It is important to measure mold temperature variability in a running state to assure that mold temperature is consistent and not affecting process via hot or cold spots in the mold during molding.

Venting: Verify that the mold has adequate venting to meet the needs of the molding application.

Validation-Process: Process validation assures that once a process has been developed, the set-up of that process will be repeatable and consistent. Here is a list of some of the primary process controls that should be reviewed to assure that an established process is true and dependable:

Melt Temperature: Melt temperature should be verified to be within the recommended temperature window supplied within MSDS data by the material manufacturer.

Barrel Temperature: While the process is in a running state, compare actual temperatures to set points. Conditions that allow heats to ride above what the set points dictate create inconsistency in the process.

Velocity vs. Fill time: Injection speed should allow room for adjustment as determined by the fill time of a process. If increasing velocity set points does not decrease the fill time, injection speed is maxed out and the potential for process variance increases.

Cushion: Cushion should remain consistent to assure that the process is stable.

Peak Pressure: Pressure at cut-off should be verified as consistent, and must not be pressure limited by the maximum pressure limit setting. The pressure limit set point should generally be about 200 PSI higher than the peak pressure achieved.

Mold & Area Set up: There are a variety of situations where slight or even major set up variations can affect the ability to repeat a process. Here is a list of factors to consider when developing your mold set up plan:

Water: It is important to repeat your water set up consistently. Once process has been established, clearly identify supply and return lines to prevent circulation from changing one set to the next. Identify hoses using color and mark circuits

Hot Runner: Whenever possible, use the same hot runner box every time you run a mold.

Clamp Force: Record and verify that tonnage used stays consistent. Variability in tonnage setpoints can lead to poor venting or flash.

Next week, part 3 of the Five M’s of Molding: Material.

Garrett MacKenzie is the owner and editor of www.plastic411.com. Mackenzie started in plastics at the age of 19 as an operator, eventually moving up through the ranks to engineering and management over a 29-year timeframe. He currently works as a plastic injection consultant in engineering and training capacities. He can be contacted at garrett.mackenzie@mail.com.

(Image courtesy Moldex 3D)

Related Content

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More