The Future of Biopolymers Looks Bright

NatureWorks’s 2016 conference showed that innovation in biopolymer technology will continue to thrive.

NatureWorks’s 2016 conference showed that innovation in biopolymer technology will continue to thrive.

Despite some pundits who opined that low oil prices would stop growth in biopolymers in its tracks, it appears that this has not come to fruition.

In fact, biopolymers are already playing a broader role in the industry: as base materials, as blends/alloys, as specialty additives, and as 3D printing filaments. This just one of the many things I learned by attending the 5th edition of Innovation Takes Root (ITR) in Orlando, Fla., a three-day event sponsored by manufacturer of Ingeo PLA NatureWorlks LLC, Minnetonka, Minn.

Global Ingeo PLA channel partners from the entire bioplastic value chain came together to learn more about the innovations emerging in a host of markets—from 3D printing to flexible and rigid packaging to durable goods. PLA is a bioplastic made up of long molecular chains of the polymer polylactide derived from naturally-occurring plant sugars, at least so far.

But change and innovation are underway for PLA, and its feedstocks, and biopolymers in general. Take for instance two key announcements that were made right around the time of this conference:

• NatureWorks opened a $1-million, 8,300-sq.ft. laboratory at its world headquarters. The new lab represents the latest milestone in a multi-year program to commercialize a fermentation process for transforming methane—a potent greenhouse gas, into the PLA building block lactic acid. The methane-to-lactic acid research began in 2013 as a joint effort between NatureWorks and Calysta Energy, Menlo Park, Calif., to develop a fermentation biocatalyst.

In 2014, laboratory-scale fermentation of lactic acid from methane utilizing a new biocatalyst was proven, and the U.S. Department of Energy awarded $2.5 million to the project. The lab’s opening represents a major step toward commercial reality.

The aim is to have a pilot plant in place within a three-to-six year time frame. Commercial success of this technology would diversify NatureWorks away from reliance on agricultural feedstocks, and with methane as feedstock, it could structurally lower the cost of producing Ingeo. The company envisions a future where greenhouse gas is transformed into Ingeo-based products ranging from compostable food serviceware, to film for wrapping fresh produce and deli packaging, to durable products such as computer cases and filaments for 3D printers.

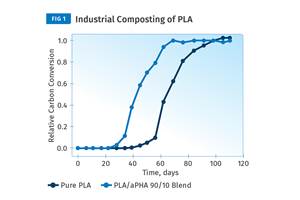

• Metabolix, Cambridge, Mass., has signed a memorandum of understanding with Korea’s CJ Cheiljedang Corp. (CJ) for a strategic commercial manufacturing arrangement for specialty PHAs, including its newly launched amorphous PHA (a-PHA)—for use as performance additives in PLA and PVC. Which brings its vision for large-scale PHA production that much closer.

Under the agreement, CJ will fund, construct and operate a 20-million/lb PHA production unit at its Fort Dodge, Iowa facility, based on Metabolix’s PHA technology. The facility is operated by CJ’s division CJ BIO, a world leader in microbial fermentation based R&D and manufacturing for a range of amino acids, including lysine, as well as nucleotides. Production startup is anticipated within the next 18-24 months. In turn, Metabolix will buy the specialty PHAs produced at the facility, and market and sell the material to its commercial customers. The team also expects to define a framework for longer-term expansion of the collaboration for larger-scale PHA production and related commercial activities.

The conference was concluded with a terrific presentation by NatureWorks’ president & CEO Marc Verbruggen (pictured below). Among the key takeways:

• Achieving sufficient economy of scale has been a critical factor.

• Diversifying product mix and markets has been key. By 2015, Ingeo PLA markets included food service wear, films, fibers, rigid packaging, durable goods, and performance chemicals.

• During oil drop-off, Ingeo sales increased in five of the company’s six businesses.

• A key goal is to develop a one-step process of turning “greenhouse gas” into PLA, which would significantly reduce feedstock costs.

• New multifunctional barrier structures allow the rethinking of flexible multilayer structures—with some packaging moving from fossil-based three-film structures to 100% biobased two-film structures.

• New advanced PLA injection molding compounds and alloys will be positioned as a functional alternative to ABS in durable applications.

Search for more of NatureWorks Ingeo PLA and Metabolix’s PHA biopolymers on PT’s materials database.

Related Content

ICIS Launches: Ask ICIS Generative AI Commodities Assistant

Said to be the first of its kind, this AI assistant will enhance access to ICIS’ intelligence and insights for the energy and chemical markets.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

Read MoreBest Practices for Purging PHA and PHA/PLA Blends

Because bioplastics are processed at lower temperatures, purging between jobs requires a different process and purging agents than those applied for traditional resins.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More