Processing Index Rallies for Another Month

With a February reading of 58.6, the index expands at its fastest rate in five years.

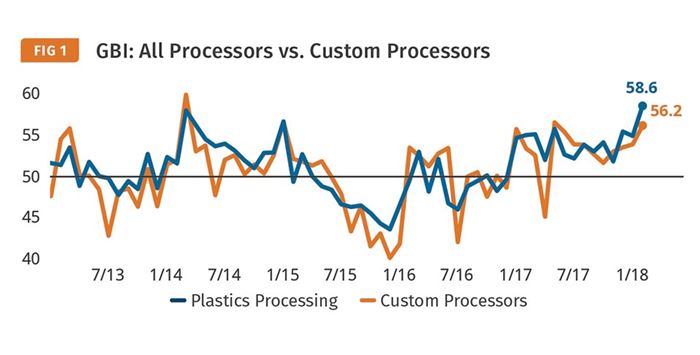

Registering 58.6 for February, the Gardner Business Index (GBI): Plastics Processing index continued its rally with a record high reading, beating the peak last set in early 2014. New orders again exceeded production for the sixth consecutive month. The GBI is based on survey responses from subscribers of Plastics Technology magazine.

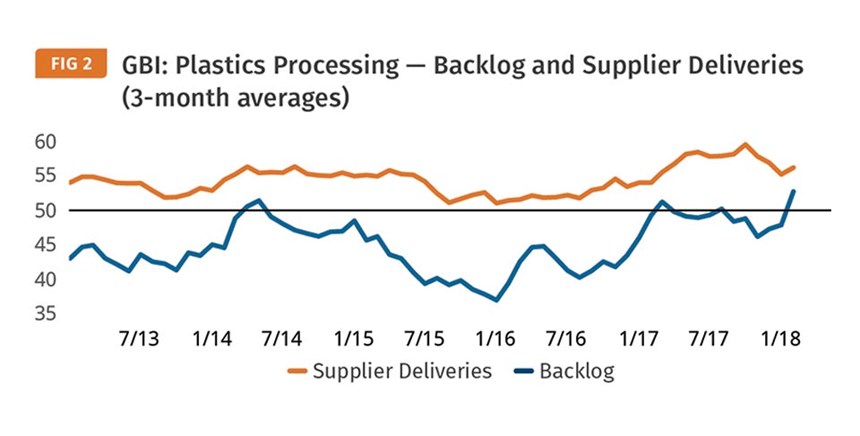

The latest index reading (see Fig. 1) was driven by production and new orders, while all other components pulled the Plastics Processing Index lower. In past months, Gardner Intelligence has reported on the muted response of backlog and supplier-deliveries readings despite new-orders growth exceeding production.

Until this month’s spike in the backlog reading to a multi-year high, prior months of backlog data have indicated a mix of contraction and at best tepid growth. February’s sharp increase in backlogs may act as the catalyst for processors to put more pressure on their suppliers and reduce backlogs in the coming months (see Fig. 2).

The GBI reading among just custom processors in February indicated increasing expansion in the industry. The latest reading was only marginally below the high of 2017 and is over 5% higher than the reading from a year ago. During the month, custom processors reported growing production and new orders. The reading for supplier deliveries was only slightly above the total index. Over the last 12 months the supplier deliveries reading is up 3%.

ABOUT THE AUTHOR: Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media, Cincinnati. He has performed economic analysis, modeling, and forecasting work for nearly 20 years among a wide range of industries. He received his BA in political science and economics from Kenyon College and his MBA from Ohio State University. Contact: (513) 527-8800; mguckes@gardnerweb.com. Learn more about the Plastics Processing Index at gardnerintelligence.com.

Related Content

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

.jpg;width=70;height=70;mode=crop)