Slower Growth Continues

Still, business among processors has grown in 10 of the last 11 months.

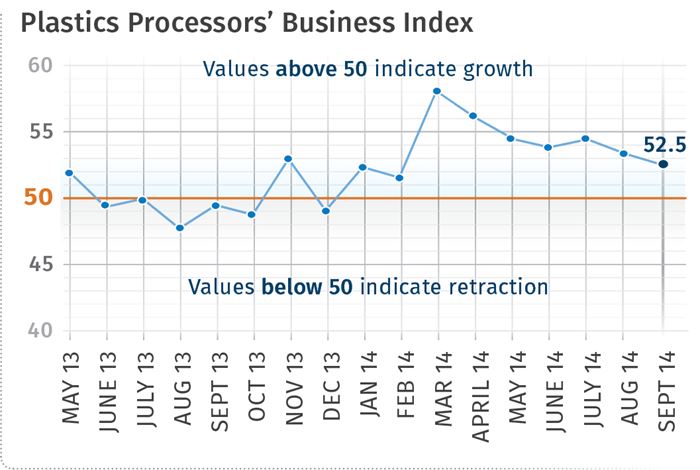

With a reading of 52.5, Gardner’s Plastics Processsors’ Business Index revealed that business grew in September among molders, extruders, and other processors for the 10th time in 11 months. The index was at its lowest level since February, though, and the processing market generally has experienced slower growth since its peak in March. Compared with a year ago, the index increased 6.5% in September. The annual rate of change has accelerated every month in 2014, reaching 7.6% in September.

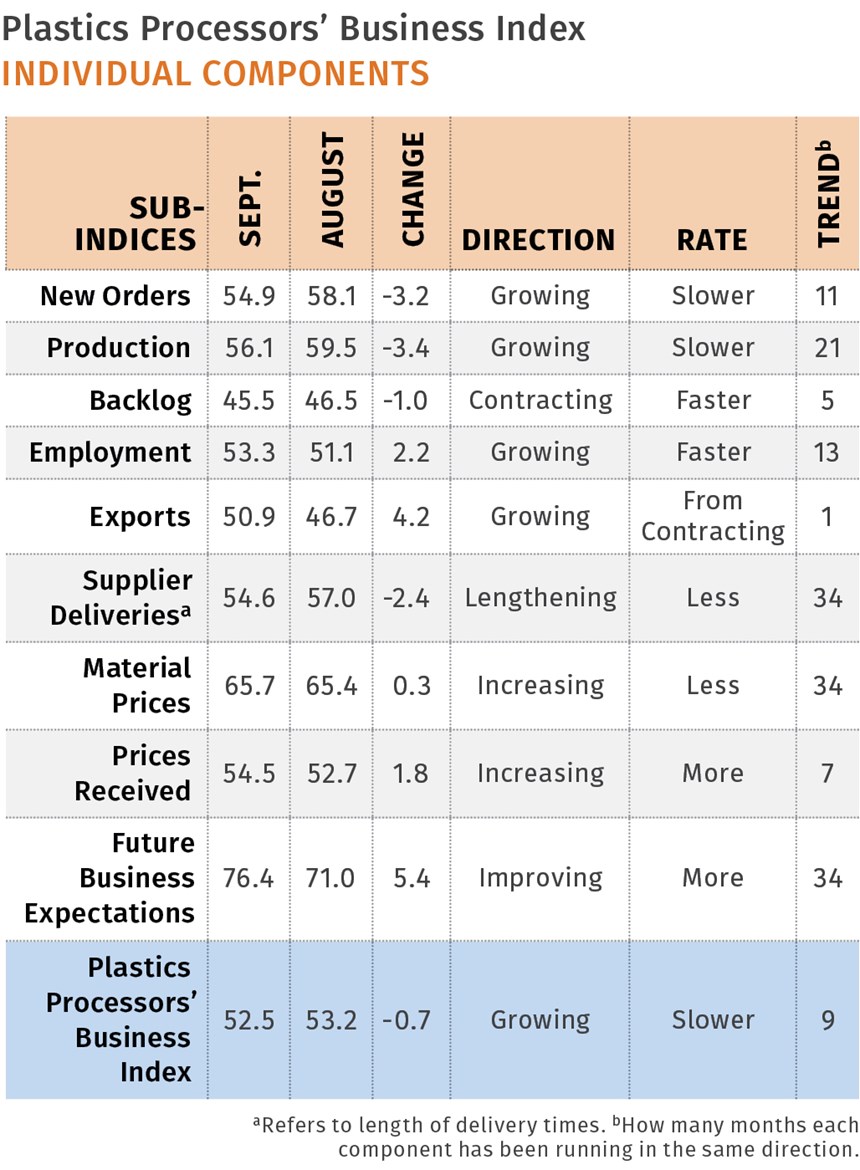

New orders for processors have grown for 11 consecutive months now. The rate of growth decelerated to its slowest pace since February. Production continued to expand, but at a slower rate than in the previous two months. Backlogs have contracted for five months in a row. The backlog index was at its lowest level of 2014 in September. However, compared with a year ago, the backlog index increased 9.9% in September.

The annual rate of change in backlogs continued to grow at an accelerating rate, which indicates that capacity utilization and capital-equipment consumption at plastic processors should increase in 2015. Employment growth accelerated from last month, but the overall trend in the index has been down since March. Exports increased for just the second time since July 2012.

Material prices have continued to increase at a significant, consistent rate for four months. Fortunately for processors, the prices they are receiving for their goods have also increased at an accelerating rate since May, and in fact have increased every month but one since December 2013. After sliding since March, future business expectations jumped significantly in September.

Facilities with more than 50 employees continued to expand at a very strong rate. Also, growth at these facilities accelerated to virtually the fastest rate since the index began in December 2011. However, at smaller processors, business conditions moved in the other direction. Processors with 20-49 employees recorded their slowest rate of growth since October 2013. Processors with 1-19 employees contracted for the fourth month in a row.

Every region but the North Central-West expanded in September. Future capital spending plans were at their lowest level since October 2012. They fell 34% compared with one year ago. This was the second time in three months that the month-over-month rate of change contracted. The annual rate of change was still growing, but at by far its slowest rate in the last year.

Related Content

-

Safety, Recycling, and Compounding Trends Bring New Opportunity to 70-Year-Old Company

NPE2024: Vac-U-Max presents pneumatic conveying solutions for powdered materials.

-

Strategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

-

How to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

.JPG;width=70;height=70;mode=crop)