Time to Step Up

Join the “conversation” about the value to society of the plastics industry.

I was at an association meeting recently when the conversation turned—as it inevitably does at these sorts of get-togethers—toward the numerous environmental challenges our industry faces. You know the list: attacks on bags, foamed PS, bottles, and now straws, etc.; and of course, the “ocean plastics” dilemma. One-by-one, at the gathering I attended, plastics industry executives discussed these issues and talked about what they—as individuals and companies—could do to reverse this growing public anti-plastic sentiment.

As folks were talking, my mind wandered and I heard a mental voice repeating what I have believed for years: “People in our industry do a great job of talking among themselves but struggle to get the word out to the masses.” The Plastics Industry Association (PLASTICS) has endeavored to change the conversation about our business with the launch of the website thisisplastics.com, which I wrote about in greater detail in the April 2018 issue. Both PLASTICS and the Plastics Division of the American Chemistry Council have done yeoman’s work—with lots more in the pipeline, I am sure—to “change the conversation,” but I think we need more input from you processors if we are really going to change how the public perceives plastics.

It’s estimated that our industry employs close to 1 million people. I’d guess that with roughly 20,000 plastics processing plants in the U.S., perhaps as many as half of those people are in facilities like yours, turning pellets into parts. So for you, there’s a lot at stake. These threats may focus directly on the products you make. If not, maybe yours will be next. Are you engaged at all in the efforts of change the conversation?

If not, I think you can take the first step my talking more to us. Full disclosure: It’s in the best interests of Plastics Technology Magazine to hear from processors. We feature plant-tour type stories that we call On-Site every issue that focus on processors. Our last editorial page every issue (Processor’s Edge) details specific strategies deployed by processors to solve a problem or gain a competitive edge. Information about processor activities is also peppered throughout this magazine (and on PTonline.com), in its Starting Up and Close-Up departments. And just this month, we have a first-hand account from a molder using thermal imaging technology.

All wonderful stuff, and we—not just our magazine, but our industry—need more of it. We need more processors using the resources available in thisisplastics.com to advocate for our industry. I’d like to see more processors (and OEMs) step up and join PLASTICS. We’d certainly like to see more processors engage with us as we attempt to shine a light on molders, extruders, and thermoformers who make remarkable and ingenious products and engage in best manufacturing processors.

But we sometimes run into stumbling blocks getting access to processing plants. On many occasions, when I’ve reached out to a company I know of or heard about, the response has been, “Where is the benefit for us to feature our company in a magazine that my competitors read? I don’t want them to know what I’m doing.”

The benefits are numerous. Some are warm and fuzzy … you can position yourself as a thought leader among your peers. But others are more tangible. You could reprint the article, for example, and figure out a way—by mail, in person, at an open house—to get it into the hands of local high-school students. Or perhaps you can put a call into the friendly editor of your local newspaper (maybe our youth does not read newspapers much anymore, but their parents do, and besides all newspapers have websites), tell them about the article, and encourage them to do one of their own.

I think efforts like this—over time—will begin to change the mindset people have about our industry. Who knows, it might even address the skills gap by getting younger people interested in pursuing careers in our business.

Related Content

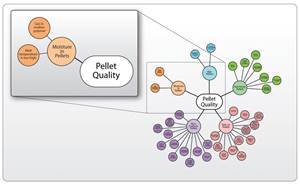

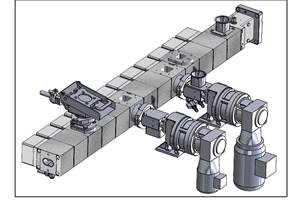

The Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More