Absolute Robot Authorized as Fanuc Robot System Integrator

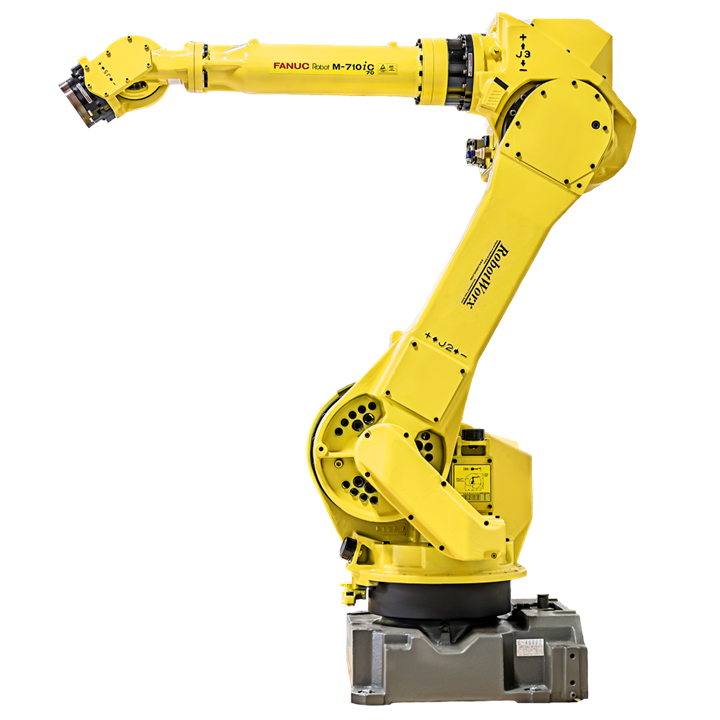

Absolute Robot is now an authorized Fanuc Robot System integrator, adding Fanuc’s 6-axis robot line to its current product offerings.

Absolute Robot Inc. (ARI; Worcester, Mass.), a supplier of 3- and 5-axis robots, end-of-arm tooling (EOAT), conveyors and guarding for the injection molding industry, will now offer 6-axis robots after becoming an authorized Fanuc Robot System integrator.

Tim Lavigne, ARI business manager, said in a release that the decision to add 6-axis robots was driven by molders’ attempts to address labor shortages and the need to operate more sophisticated machine cells. ARI has completed a range of projects featuring Fanuc 6-axis robots, including systems integrated with vision inspection, laser marking, de-gating, labeling, and more.

Going forward, ARI will offer customers interested in Fanuc 6-axis robots engineering and design; custom cell fabrication and factory acceptance testing; installation, programming and on-site training; and after sale support. Cells can be designed for a range of applications from pick and place; packaging and palletizing; insert molding; de-gating; vision inspection; and assembly.

ARI said the decision to standardize on Fanuc Robots for 6-axis and SCARA applications was based on that company’s leadership position in the North American market. ARI’s robot offerings range from pneumatic pickers through full-servo robots that may be equipped on injection molding machines with up to 3300 tons of clamp force.

Absolute Robot has added 6-axis robots to its portfolio after becoming an authorized Fanuc Robot System integrator.

Photo Credit: Fanuc

Related Content

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Drones and Injection Molding Ready for Takeoff

Drones and unmanned aerial vehicles (UAV) are approaching an inflection point where their production volumes — and functionality — will increasingly point to injection molding.

-

Automation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.