ADS Planning $65 Million Expansion at Ohio HQ

ADS Engineering & Technology Center to add jobs, and expand state-of-the-art capabilities in materials science, manufacturing technologies and stormwater and onsite septic wastewater management solutions.

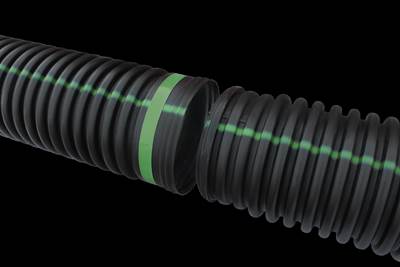

Advanced Drainage Systems Inc. a leading processor of corrugated pipe and water-management solutions and the largest plastic recycler in North America, has announced plans to invest a total of approximately $65 million in Hilliard, Ohio, near the company’s existing headquarters. This investment will fund the development of a nearly 110,000-ft2 industry-leading Engineering & Technology Center.

“The ADS Engineering & Technology Center will be the most advanced stormwater engineering center in the world dedicated to product engineering, material science –– including recycled plastics –– and manufacturing technologies. This new facility will accelerate our development of products designed to capture, convey, store and treat our most precious resource: water,” said ADS President and CEO Scott Barbour.

The company plans to break ground in October at a 17-acre site west of ADS’ headquarters. Barbour said the new facility is expected to open in late 2023.

“Clean water is critical to our economy and quality of life, and with talent from Ohio, ADS is not only protecting our water supply but also strengthening its position as the largest plastic recycler in North America,” said Ohio Gov. Mike DeWine. “The new, cutting-edge facility that ADS is bringing to Ohio will advance technologies that preserve our natural resources and improve our environment while creating 200 new jobs in Hilliard.”

The expansion to ADS’ engineering and technology operations at the center will allow the company to consolidate all of the current product development and testing operations and manufacturing engineering development into one central location. It will include:

- A product development lab focused on the full range of a product’s life cycle including:

- An area to prepare product samples for testing.

- A fabrication lab to develop prototype parts and test fixtures.

- A lab to analyze structural performance of prototypes under different conditions.

- A 3D printing lab to rapidly develop and vet concepts.

- A hydraulics lab that supports ADS’ water treatment businesses including separation, traditional filtration and low impact development filtration.

- An advanced technology lab for manufacturing and engineering prototyping.

- Materials science laboratories providing:

- Extensive performance-based materials test capability.

- Analytic tools to generate structural and chemical information on investigated materials.

- Extrusion capability for development of next-generation product formulations.

The Ohio Tax Credit Authority also announced today it will provide ADS with tax credit assistance to continue the company’s expansion in Hilliard. In return, the company must invest at least $10.8 million into the project, retain 322 existing jobs currently in Hilliard, and create 200 new jobs that would result in $20 million of new payroll to the state. All told, ADS plans to invest approximately $65 million in construction and equipment for the new engineering center.

ADS also received significant assistance from JobsOhio, Ohio’s unique private economic development corporation, and One Columbus, its regional economic development partner, in site selection and connecting ADS with the appropriate economic development and city partners to ensure successful completion of the project.

Barbour said the building and property will facilitate LEED Silver certification and be a showpiece for ADS employees, customers and investors.

“As the largest plastics recycler in North America, utilizing LEED building techniques supports our commitment to sustainability and advances progress to meeting ADS’ 10-year sustainability goals,” said Barbour. “The design of this facility will also enable safe observation of the exciting products and technologies that make ADS the world’s leading stormwater and on-site septic wastewater solutions provider.”

Related Content

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreRead Next

10 Billion Feet…And Counting

‘Our reason is water.’ Those four words explain a focused strategy that helped Advanced Drainage Systems evolve from a two-man startup into a global supplier of corrugated pipe and water-management solutions with 10 billion+ ft of pipe in service all over the world.

Read MoreBlazing the Trail In Processing PCR for Corrugated Pipe

Just a decade ago, roughly 10% of HDPE corrugated pipes made by Advanced Drainage Systems used recycled material. That number is 65% now, and growing. Here’s how this processor became a pioneer in this field.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More