ALPLA to Add Facility in Missouri

The 246,000-ft2 greenfield site in Kansas City will be dedicated to injection molding and completed in late 2022, with groundbreaking slated for later this year.

Rigid plastics packaging manufacturer ALPLA (Hard, Austria) will break ground on a new manufacturing plant in Kansas City, Mo. later this year. Dedicated to injection molding, the newest site, which will cover 246,000-ft2, is the fourth operation ALPLA will have in Missouri.

Construction on the rail-served injection molding facility will begin in late 2021 with completion planned for late 2022. The newest facility is expected to employ 75. The company’s other sites in Missouri are located in St. Peters (2) and Jefferson City. Elsewhere in the U.S. it has operations in Georgia, Pennsylvania, Utah, Ohio, Iowa, Wisconsin and Kentucky.

ALPLA employs 21,600 globally producing custom-made packaging systems, bottles, caps and molded parts from 178 sites across 45 countries. Of those 178 plants, 68 are captive operations located with a customer’s facility. In North America, ALPLA focuses on bottles and caps for the food, beverage, auto, health, beauty, and home care industries. The company operates its own recycling plants for PET and HDPE in Austria, Poland, Mexico, Italy and Spain. Founded in 1955, it generated revenue of Euro 3.69 billion in 2020.

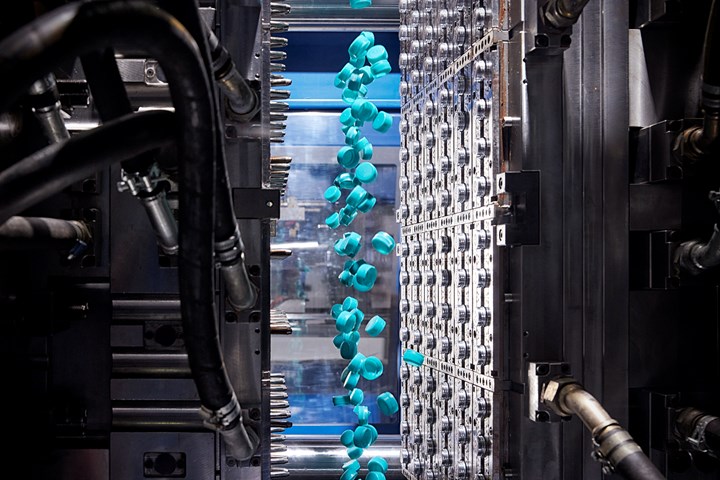

ALPLA’s newest facility in Kansas City will focus on injection molding. In North America, the rigid packaging manufacturer focuses on bottles, caps and closures production.

Photo Credit: ALPLA

Related Content

-

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.