Arkema Invests in Continuous Composites

Arkema has invested in the American start-up to advance the development of 3D composite manufacturing.

Arkema invests in 3D printing U.S. startup.

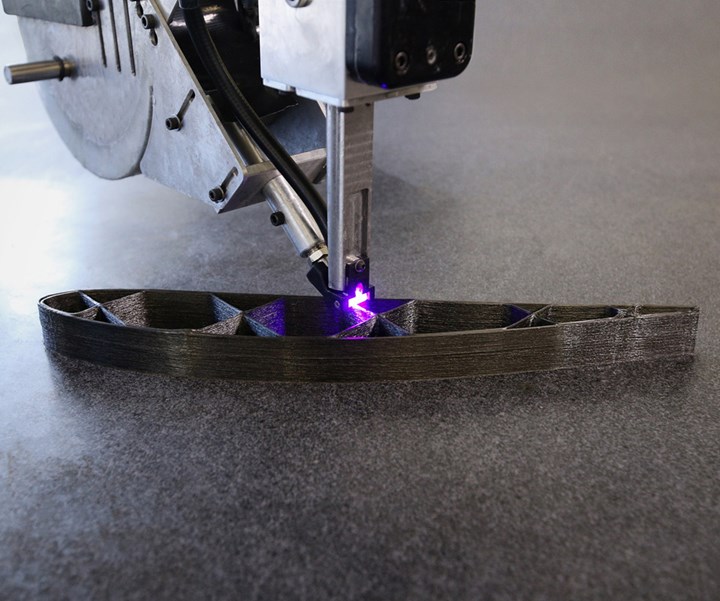

Arkema is investing in Continuous Composites, creator of the Continuous Fiber 3D Printing technology (CF3D). The companies seeks to advance the development of 3D composite manufacturing.

Continuous Composites’ offerings include its patented CF3D technology that features a complete solution including software, hardware, materials and motion platforms. The company says its core technology is advancing composites design and manufacturing capabilities utilizing high-performance thermosets resins.

With expertise in designing photocurable liquid resins, Arkema – through its Sartomer business line - has a specific N3xtDimension offering for additive manufacturing processes and is now developing a new generation of solutions with their use for CF3D. N3xtDimension is part of the 3D Printing Solutions by Arkema platform, delivering an array of solutions for all major 3D manufacturing technologies worldwide.

“We are delighted to strengthen our strategic partnership with Continuous Composites, which has an agile, reliable team with a very strong entrepreneurial spirit. Our investment is a testament to our belief in the market opportunity of CF3D. This collaboration will accelerate the development of innovative materials and disruptive manufacturing technology,” said Sumeet Jain, senior worldwide director of 3D printing solutions by Arkema.

Having signed a Joint Development Agreement (JDA) in September 2019 the two companies have already reportedly succeeded in hitting key milestones with the ongoing co-developments focused on progressing N3xtDimension photocurable resins for the CF3D process. This co-innovation has enabled the production of customized and large-scale composite parts with high performance mechanical properties for applications in aeronautics, automotive, and energy sectors, among many others. Current development development projects include collaborations with Lockheed Martin (US), Air Force Research Laboratory (US) and Siemens.

Related Content

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

-

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.