Chemical Recycling Trials for Glass-Reinforced Nylon

Honda and Toray are jointly validating a process for recycling Nylon 6 with automotive applications.

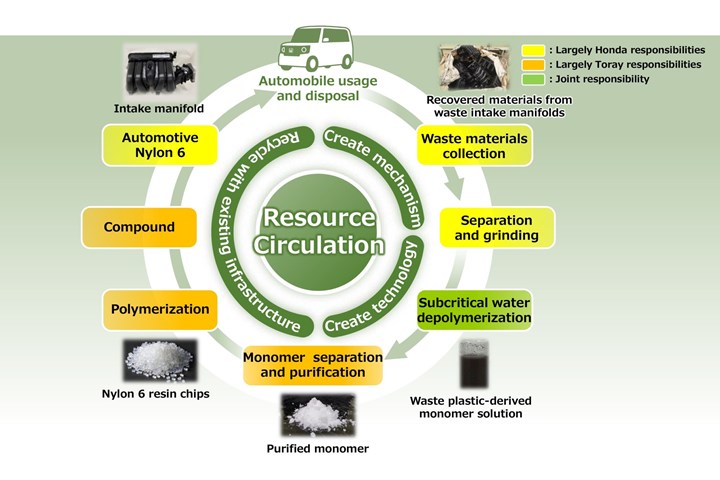

Toray announced an agreement with Honda to jointly develop chemical recycling technology for glass-fiber reinforced nylon 6 (polycaprolactam or PA6) parts from end-of-life vehicles. The technology entails depolymerization with subcritical water and regenerating the materials as caprolactam monomer.

Individual and joint contributions to Toray/Honda Recycling Project. Photo Credit: Toray Industries

The companies chose to focus on subcritical water for its dissolving power and hydrolysis effect on resins. According to Toray, depolymerization of nylon 6 with subcritical water can generate high yields of raw monomer. Separating, refining and repolymerizing the monomer generates nylon 6 that performs like a virgin material.

Japan’s Ministry of the Environment adopted this technology for a fiscal 2023 project to establish a decarbonized circular economy system, including validation of recycling systems for plastics and other resources. Toray and Honda look to employ that project to set up a pilot facility with a processing capacity of 500 metric tons annually of raw resin, conducting validation testing with it.

The two companies will develop depolymerization and monomer separation and refining technologies by employing intake manifolds as raw materials for engine intake system parts. They seek to apply these technologies for recycling chemicals in automotive resin parts by around 2027.

Related Content

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

-

BASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.