Conair Parent Buys Conveying Systems Firm

IPEG purchases long-time partner company Phoenix Systems, which makes powder and pellet conveying and unloading equipment used by processors in high-volume applications.

Conair parent IPEG has bought Phoenix Systems Corp., a California-based builder of pellet and powder conveying systems geared for processors in packaging and other markets where material consumption is high. Financial terms of the deal, which closed on Dec. 21, 2020, were not disclosed.

The two companies have worked together on projects for more than 20 years, according to a press release issued by IPEG. As a result of the transaction, Phoenix and its product line will be rolled into Conair, which already offers a wide array of conveying systems among other types of auxiliaries.

The move “bolsters Conair’s bulk material-handling capabilities and enhances its ability to serve customers in certain industries, like packaging, which consume high-volumes of material,” said Kirk Winstead, IPEG president. “We also acquired the applications knowledge and intellectual property, which will allow us to more easily develop new products and extend the line further.”

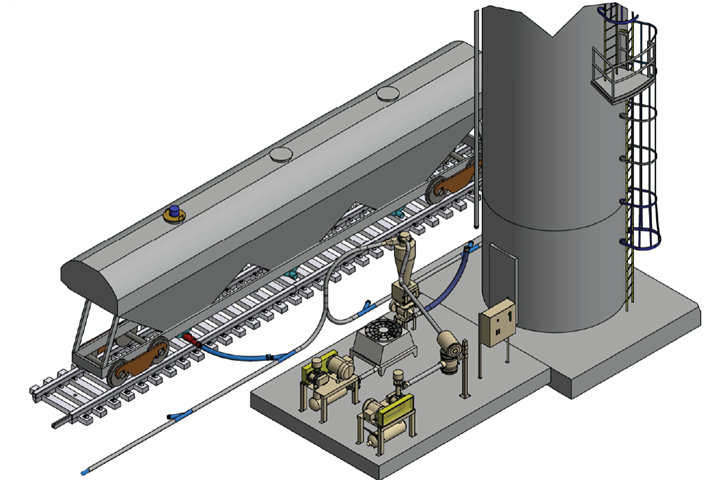

Phoenix’s product line includes railcar unloading systems for powder and pellets, pressure-blowing systems, vacuum-blowing systems, blending silo systems, cyclones, dust collectors, and other devices.

In addition to packaging, Phoenix’s website reveals the company’s technology is utilized in high-volume building and construction markets such as pipe and profiles, compounding and recycling.

Leroy Johnson, former owner of Phoenix Systems, said he was “fortunate to have had a very successful working relationship with Conair for many years. Conair’s emphasis on excellence in customer service and satisfaction aligned closely with my belief that putting the customer first builds strong and loyal customer relationships. As I considered retirement, it was a natural progression to transition my products into the Conair brand.”

IPEG is also the parent company to plastics machinery makers Thermal Care, Pelletron and Republic Machine.

Schematic demonstrates product combinations offered by Conair (silo) and Phoenix (equipment on left pad).

Related Content

-

New Pump Rewrites Conveying Rules

NPE2024: Smart Pump technology brings more flexibility and finesse to resin conveying.

-

Technology Aims to Smarten Up Resin Conveying

At NPE2024, Novatec moves to rewrite the rules for material conveying with patent-pending smart-pump technology.

-

Artificial Intelligence Manages Changing Conveying Conditions

NPE2024: Billed as an industry first, controls autonomously adjusts the conveying system in real-time to move material under optimal conditions.