Coronavirus Doubles Demand for Used Blow Molding Machines

Demand for hand sanitizer, alcohol, cleaning products and beverages is reportedly straining capacity in blow molding.

“The used machinery market since February is experiencing huge demand and supply swings that are affecting used machine prices,” says Gema Álvarez, marketing & PR director of MachinePoint, a global dealer in used plastics machinery, based in Spain with offices in the U.S., Mexico and 10 other countries (machinepoint.com). Attributing this instability to the coronavirus pandemic, she adds, “Blow molding machines of all kinds (stretch, injection-stretch or extrusion) have doubled in demand and halved in supply,” adds Álvarez, in response to soaring demand for hand sanitizers, alcohol, glycerin, bleach, cleaning products, and beverages like water, juices and beer. “The bottle and bottling industry is producing at 100% above their regular capacity, running up to five shifts in some cases.”

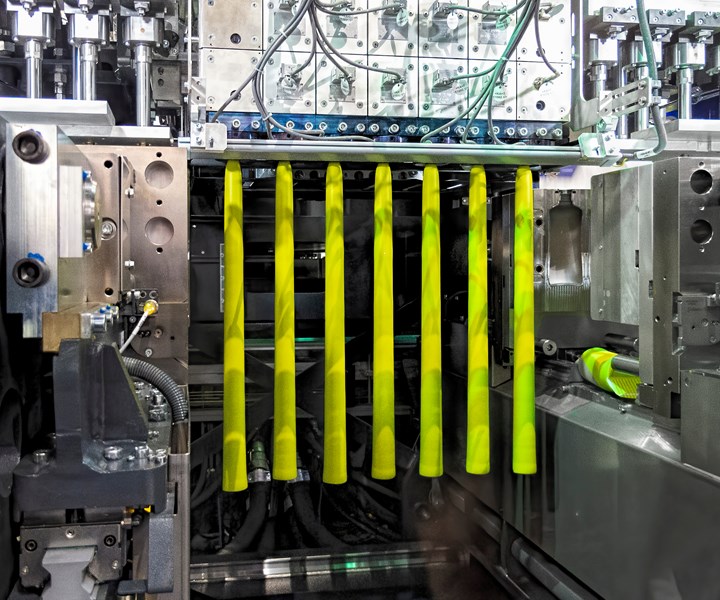

Trade barriers reportedly are holding up shipments of urgently needed equipment and tooling. (Photo: Plastics Technology)

Injection molding machinery for crates is also in higher demand, she notes, as consumers stock up their home inventories. “While a large part of the economy stands still, the flexible packaging industry is at full capacity, running 30% above normal levels.” MachinePoint also handles film extrusion equipment.

An additional factor, Álvarez notes, is governments closing borders and disrupting trade. “We have many machines waiting to be picked up due to trade barriers at origin, destination or transit countries.” Making things worse, “Cargo air fare is at 300% of the prices before COVID-19. We are having to accept these prices to ship molds, hot runners, or die heads that are urgently needed in Germany, Italy, Spain, Mexico or the United States.”

Related Content

-

Krones Acquires Netstal

Krones adds PET preform injection molding to its bottle blowing and filling capabilities, as well as cap molding and expansion into medical, food and other markets.

-

Catheter Specialist Finds Sweet Spot Serving Small, Medium-Sized Concerns

Medical-component specialist LightningCath has carved a niche meeting the needs of small to medium-sized entrepreneurs with complex catheter designs … quickly.

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.