Dow, Circusil Collaborating on Silicone Recycling Facility

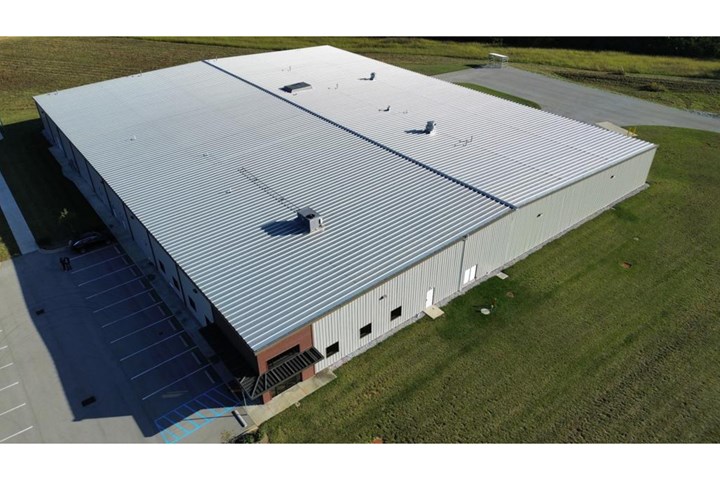

Dow and Circusil announced plans to construct a silicone recycling facility in Kentucky.

Dow Chemical and Circusil announced a partnership to start a silicone recycling facility in Kentucky. This facility will recycle silicone waste streams from Dow’s U.S. operations as well as postindustrial waste streams from customers. Operations are targeted to begin in fourth quarter of 2024.

The company describes the recycling process as “advanced recycling,” and says the recycled material will be reintroduced to silicone production.

The process involves depolymerizing silicone polymers to create monomers, which will in turn be repolymerized to polydimethylsiloxane (PDMS).

Dow projects that by recycling silicone waste streams, the company will be able to reduce the carbon footprint of PDMS by more than half when compared to virgin production. Recycling circumvents the production of silicon metal, which represents 55-65% of the traditional process for making silicones. Recycling can also reduce Scope 1 emissions (directly attributable to the company) and Scope 3 emissions (downstream from company operations) associated with incineration or landfilling of silicone materials at end-of-life. These results are pending critical review of life cycle analysis by an independent third party (per ISO 14040/44).

Dow expects the new facility in Paris, Kentucky, will enable its customers to: reduce the carbon footprint associated with disposal of silicone waste, meet growing demand for silicone polymers with recycled content, and accelerate progress toward sustainability objectives.

“Our partnership with Circusil LLC to establish silicone recycling capabilities in North America marks a major stride forward in our pursuit of circularity. It reflects our ambition to lead silicone recycling at scale,” says Eric Peeters, vice president for Dow Performance Materials & Coatings. “As a global silicone manufacturer, we are actively delivering on our commitment to drive circularity aiming to achieve a closed-loop system on this extremely valuable material, while lowering the carbon footprint of silicones.”

Related Content

-

How to Optimize Color Evaluation of Recycled Plastics

The right color measurement instrument and good working methods will minimize variability in color evaluation of PCR.

-

Evolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

-

BASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.