Film Structure Designs Formulated with PCR Debuted by Nova Chemicals

Nova’s new series of customizable film structure designs formulated with post-consumer resin.

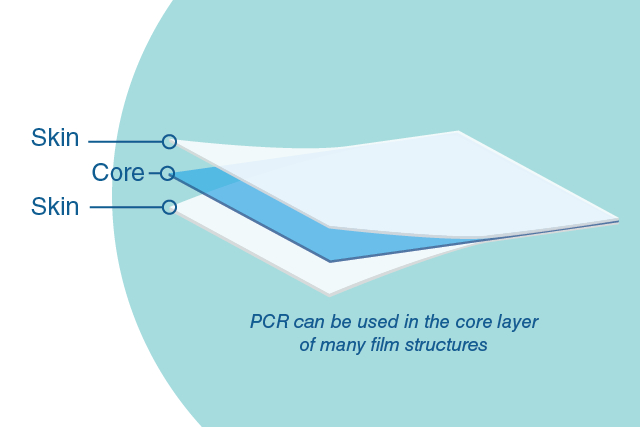

A new series of customizable polyethylene film structure designs formulated with post-consumer resin (PCR) has been developed by Nova Chemicals, Pittsburgh, Penn. The film structures, which incorporate rLDPE and rLLDPE can be tailored to meet the demands of film applications including heavy-duty sacks, collation shrink, stretch film, agricultural film, trash bags and liners, food packaging and protective packaging for e-commerce, such as bubble wrap and air pillows.

Noting that the new film structure designs further advance the company’s commitment to supporting industry-wide adoption of PCR, v.p. of PE marketing Greg DeKunder said, “The introduction of these film structure designs is one of several initiatives we are pursuing to make it easier and more practical for the industry and our customers to incorporate PCR into new packaging and products. The addition of our portfolio of PCR will allow Nova Chemicals to be a one-stop supplier for our customers’ virgin and recycled polyethylene needs.”

The film structure designs also are a vital step in helping consumer brands meet their ambitious sustainability goals, according circular economy market manager Monika Kleczek, “The PCR teams at our Innovation Centres are working closely with film producers, converters and brand owners to design high-performance PCR-content consumer packaging. Together, they are accelerating commercialization of these packages and advancing the circular economy.”

Last year, Nova entered into agreements with Merlin Plastics and Revolution to supply PCR that Nova Chemicals will sell to its customers. The company also introduced a suite of ready-to-recycle resins in 2019, which, in their virgin state, are designed to compensate for the potentially degraded physical performance of recycled content in film structures. Customers seeking to incorporate PCR into their film designs also are supported by Nova Chemicals’ Innovation Centres, which are staffed by a dedicated team of PCR experts and equipped with industry-leading production, conversion and testing equipment.

Related Content

-

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.