Foster is Now Exclusive Distributor for SK Functional Polymer

The new partnership allows Foster to offer Orevac 18300M functional engineering PE tie layer to the medical device industry.

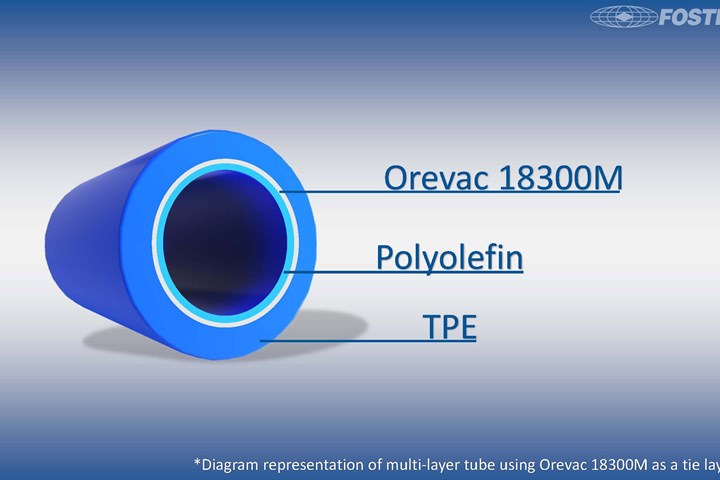

Foster Corporation has entered into an exclusive sales agreement with SK Functional Polymer (SKFP), a subsidiary of SK Global Chemical, a leader in functional polymers. The agreement allows Foster Corporation to exclusively service the North American medical device market with Orevac 18300M, a functional engineering PE-based tie layer. Such a tie layer polymer is specifically designed to bond together two or more incompatible materials that are used in an extruded or injection molded medical component.

Foster currently provides highly engineered materials and compounds that are used in specialty medical and life science applications. Said Laurent Cartier, business manager for SK Functional Polymer - North America. “This partnership will allow SKFP to promote their Orevac brand into medical device applications and extend its position in multi-layer medical film, sheet, and tubing products. The company will increase its visibility and presence into medical device market while Foster will be able to provide a complete materials solution - including the tie layer - to their customers.”

Foster’s v.p. of business development Larry Johnson noted that the Orevac brand has been a quality brand for years in the industrial market. “Now, Orevac 18300M will be available to medical OEM’s as a material tool to solve difficult extrusion and injection molding adhesion, and joining issues more effectively than what has been available.”

Related Content

-

Fundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

-

Prices Flat-to-Down for All Volume Resins

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

-

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.