Glass-Reinforced Nylon 66 Compounds Selected for Water Pumps

Domo’s Technyl nylon compound selected by manufacturer of pumps for building services, water management and industrial applications.

A 30% glass-reinforced nylon 66 injection molding compound which is also heat stabilized and glycol resistant, and said to grant stable performance in permanent contact with water, has been selected by Wilo (U.S. office in Rosemont, Ill.), for its premium pump and pump systems for building services, water management and industrial applications. The material is part of the advanced Technyl nylon compounds produced by Belgium’sDomo Chemicals (U.S. office in Buford, Ga.)

The two companies say they have common goals in contributing to urbanization megatrends: both are aiming to make complex technologies user-friendly, simple to use, energy-efficient and high-performance. Wilo products are said to combine top-rated performance, German engineering and world-class materials. They are designed to provide maximum efficiency for heating and cooling systems.

Within the heating subsegment, Domo Chemicals offers several options especially developed for applications in circulation pumps. The material of choice for Wilo is Technyl A218 V30 Black 34NG, used for the production of Wilo Para MSL/6-43/SC circulation pump, for heating systems, according to Domo account manager Manuel Rossi.

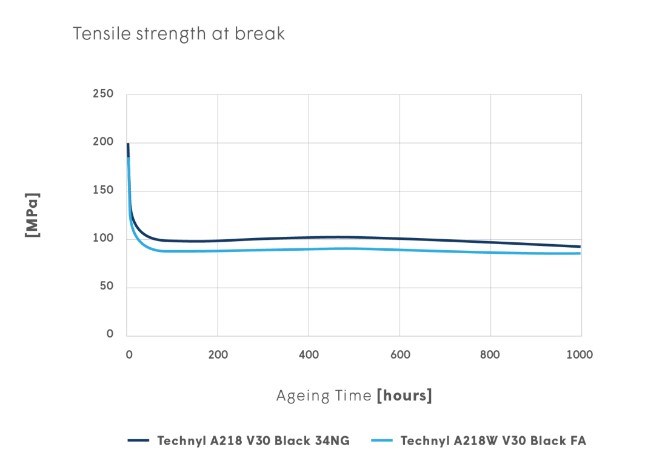

A second grade, approved for drinking water-contact applications, is Technyl A218W V30 BLACK FA. The two grades show very similar performance in glycol aging, with Technyl A218 V30 Black 34NG marginally superior.

The APT (Application Part Testing) laboratory in Domo’s Engineered Materials division is well equipped to test specimens and final parts for water management applications. Key properties can be evaluated under even the most extreme conditions on specimen and final parts. Water temperature, pressure, flow rate, concentration of different substances (chlorine, oxygen, for example), pH, and other parameters can all be modified and controlled. Results from the tests make it possible to forecast performance over entire envisaged product lifetimes.

Says sales director for Domo’s C&E market Lorenzo Tellini, “In the past couple of years, we have developed several successful solutions for the water management market. Our technical team has a deep understanding of its needs as well as the know-how on how to meet them. This is all at the service of end users to optimize and boost the efficiency of their production and their products.”

Related Content

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Lanxess and DSM Engineering Materials Venture Launched as ‘Envalior’

This new global engineering materials contender combines Lanxess’ high-performance materials business with DSM’s engineering materials business.